Menu

Understanding Hydraulic Pumps

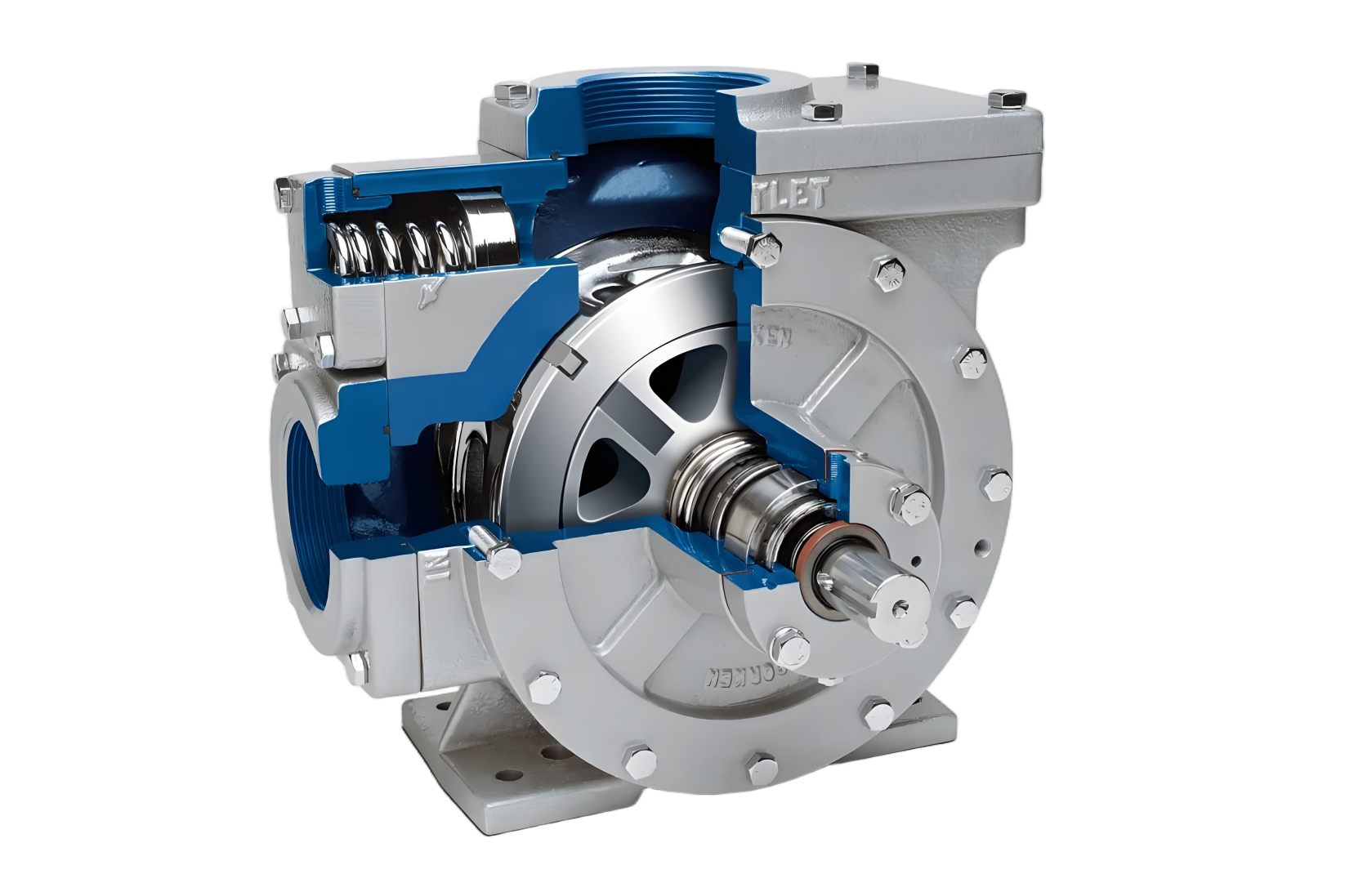

Hydraulic pumps are the heart of any hydraulic system, converting mechanical energy into hydraulic energy (fluid pressure). These essential components power machinery across countless industries, delivering precise control and immense power in compact designs. At Pozoom Hydraulic, we specialize in providing high-quality Hydraulic pumps tailored to meet the most demanding applications.

Power Transmission

Hydraulic pumps efficiently transmit power through fluid mechanics, enabling precise control over force and speed in machinery operations. This makes them indispensable in applications requiring both power and precision.

Mechanical Advantage

By utilizing Pascal's principle, Hydraulic pumps multiply force, allowing small mechanical inputs to generate massive output forces, essential for heavy lifting and machinery operation.

Industrial Versatility

From construction equipment to manufacturing lines, Hydraulic pumps provide reliable power in diverse environments, adapting to varying pressure requirements and operational conditions.

The Evolution of Hydraulic Pumps

The history of Hydraulic pumps dates back to ancient civilizations, with early water pumps utilizing basic hydraulic principles. However, modern Hydraulic pumps as we know them emerged during the Industrial Revolution, with significant advancements in the 20th century.

Today, Hydraulic pumps incorporate advanced materials, precision engineering, and computer-aided design to deliver unprecedented efficiency, durability, and performance across industrial applications.

Types of Hydraulic Pumps

Pozoom Hydraulic offers a comprehensive range of Hydraulic pumps, each designed for specific applications and performance requirements. Understanding the differences helps in selecting the optimal solution for your needs.

TYPE 01

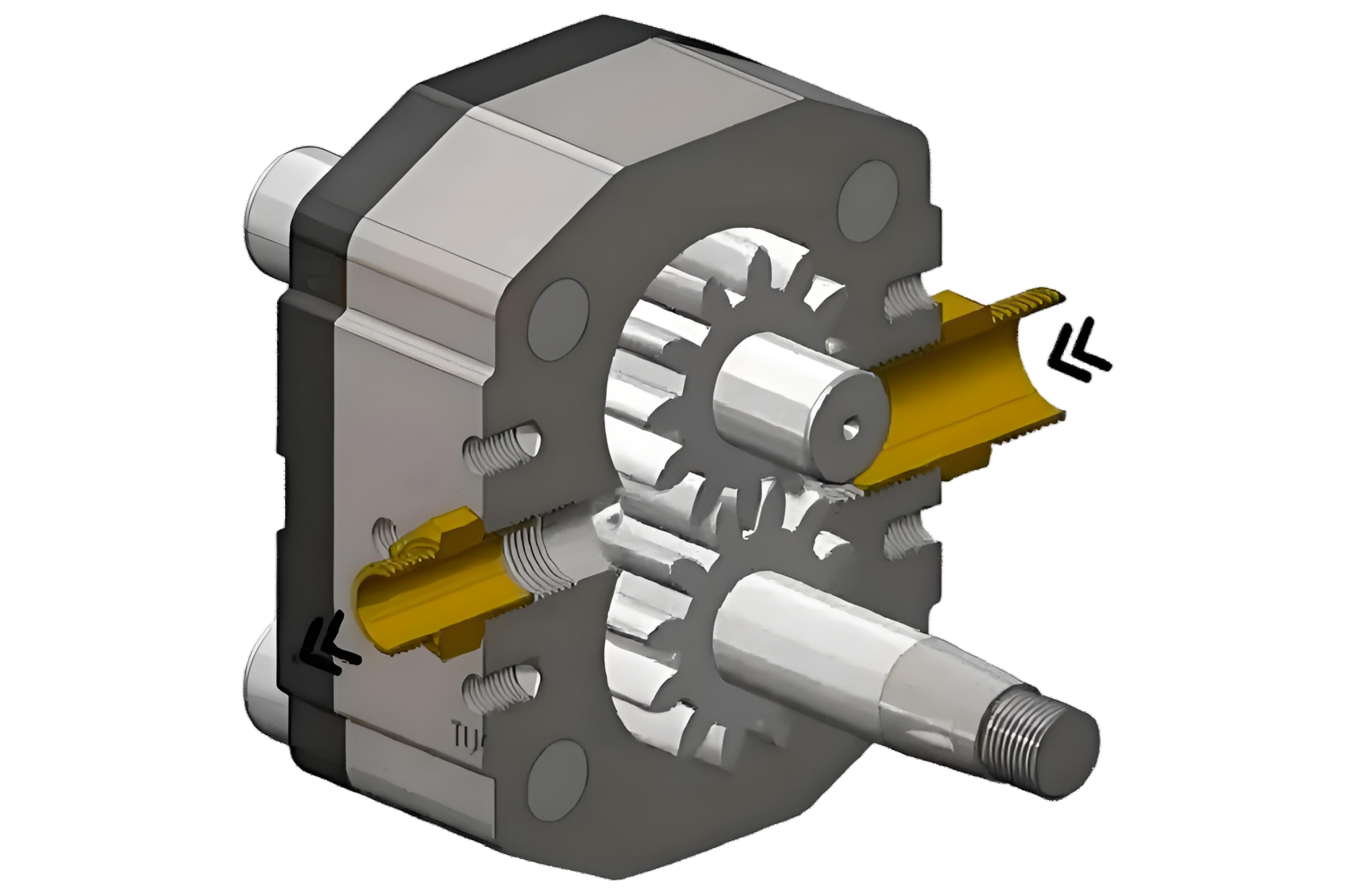

Gear Pumps

Gear pumps are one of the most common types of Hydraulic pumps, valued for their simplicity, cost-effectiveness, and reliability. They operate through the meshing of two gears that displace fluid as they rotate.

Simple design with few moving parts

Cost-effective manufacturing

Compact size for space-constrained applications

Continuous, pulse-free flow

These Hydraulic pumps are ideal for low to medium pressure applications (up to 250 bar) and are commonly used in machine tools, plastic injection molding machines, and mobile hydraulic systems where cost and simplicity are priorities.

Learn more about our gear pumps

TYPE 02

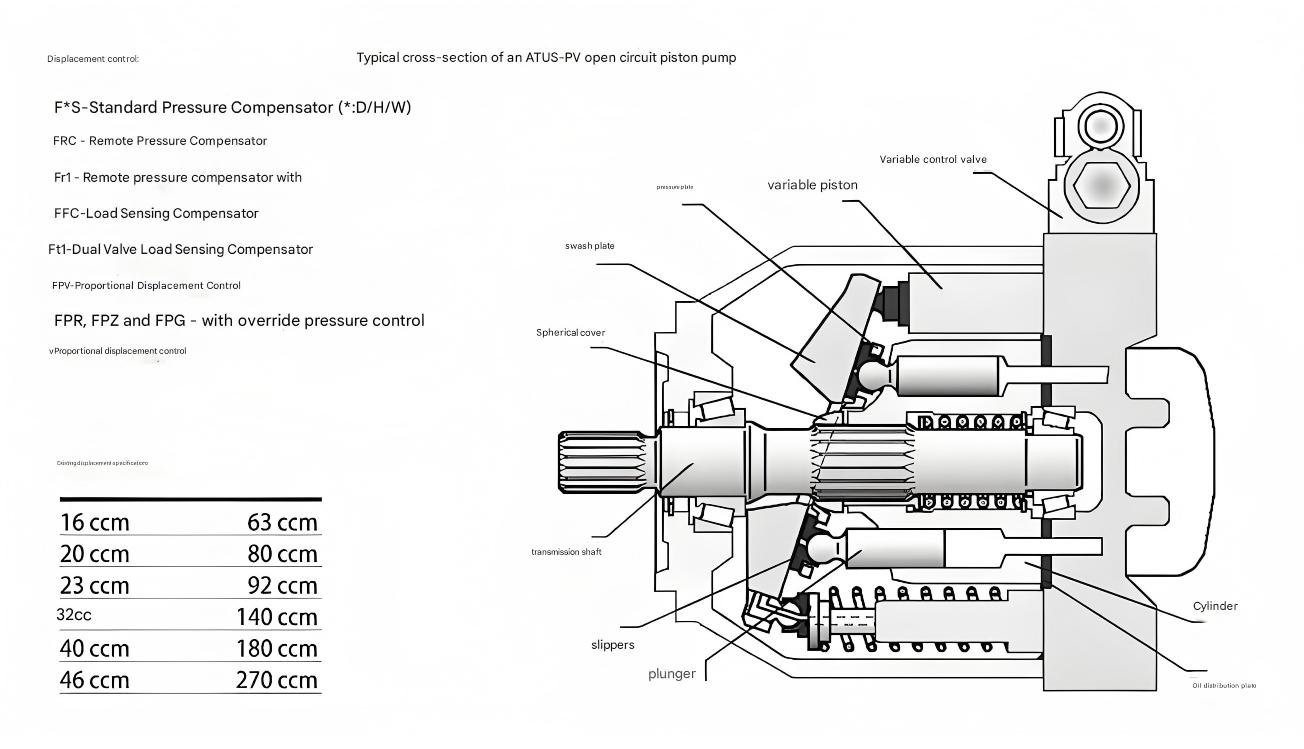

Piston Pumps

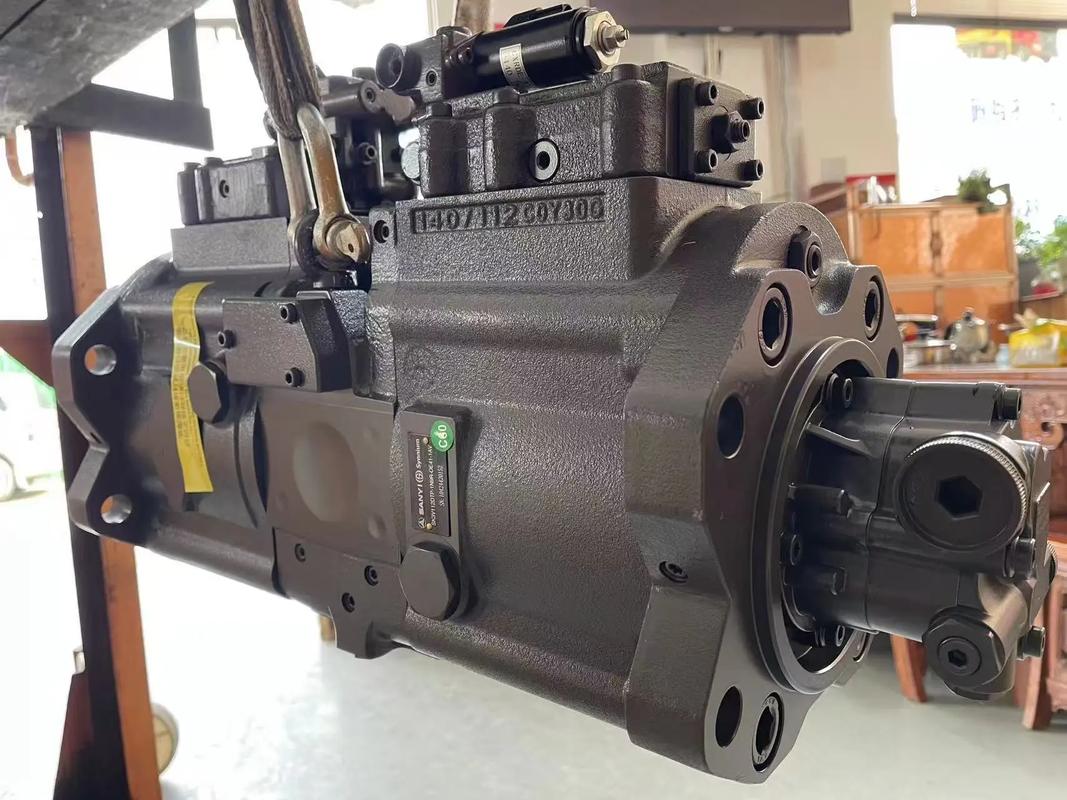

Piston pumps represent the high-performance category of Hydraulic pumps, capable of delivering high pressure and precise flow control. They operate through reciprocating pistons within a cylinder block.

High pressure capability (up to 700 bar)

Excellent efficiency (up to 95%)

Variable displacement options

Precise flow control

These Hydraulic pumps are preferred for heavy-duty applications requiring high power density, such as construction equipment, mining machinery, and industrial presses. Their ability to vary displacement makes them highly efficient for applications with varying load demands.

Learn more about our piston pumps

TYPE 03

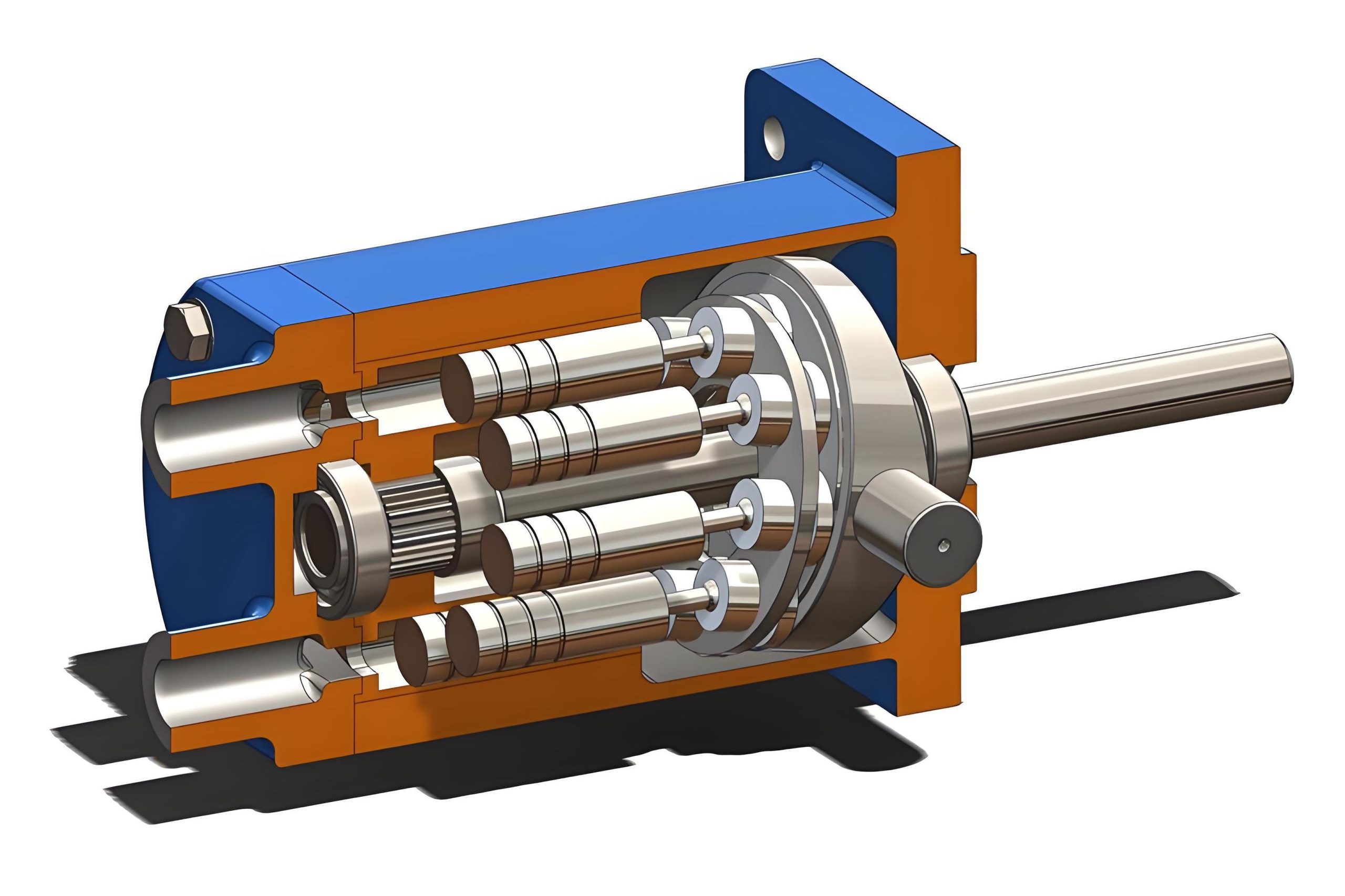

Vane Pumps

Vane pumps offer a balance between the simplicity of gear pumps and the performance of piston pumps. These Hydraulic pumps use sliding vanes in a rotor to create vacuum and pressure zones that move fluid through the pump.

Smooth operation with low noise

Good efficiency across varying speeds

Self-priming capabilities

Medium pressure range (up to 175 bar)

Vane-type Hydraulic pumps are commonly used in automotive applications, machine tools, and industrial systems where quiet operation and consistent performance are important. Their design allows for better efficiency than gear pumps while maintaining relatively simple construction.

Learn more about our vane pumpsHydraulic Pumps Comparison

| Parameter | Gear Pumps | Piston Pumps | Vane Pumps |

|---|---|---|---|

| Pressure Range | Up to 250 bar | Up to 700 bar | Up to 175 bar |

| Efficiency | 60-80% | 85-95% | 70-85% |

| Cost | Low | High | Medium |

| Noise Level | Moderate | Higher | Low |

| Maintenance | Low | Higher | Moderate |

| Fluid Cleanliness | Moderate tolerance | Highly sensitive | Moderate sensitivity |

How Hydraulic Pumps Work

Understanding the fundamental principles behind Hydraulic pumps is essential for selecting the right pump and maintaining optimal system performance. All Hydraulic pumps operate on basic fluid dynamics principles.

Pascal's Law: The Foundation of Hydraulics

The operation of all Hydraulic pumps is based on Pascal's Law, which states that pressure applied to an enclosed fluid is transmitted undiminished to every part of the fluid and the walls of its container. This principle allows Hydraulic pumps to multiply force through fluid pressure.

Mathematically, this is expressed as pressure (P) equals force (F) divided by area (A): P = F/A. When a small force is applied to a small area, it creates pressure that can generate a larger force over a larger area, enabling the impressive power multiplication seen in hydraulic systems.

Hydraulic pumps create flow that generates this pressure when met with resistance in the system, providing the power needed for various mechanical operations.

Basic Pump Operation

All Hydraulic pumps operate through a basic cycle of creating a vacuum to draw fluid in and then applying pressure to force the fluid out. This two-stage process—intake and discharge—is fundamental to pump operation.

- The pump creates a low-pressure area at the inlet port

- Atmospheric pressure pushes fluid from the reservoir into this area

- Mechanical action moves the fluid to the discharge side

- The fluid is forced out at high pressure through the outlet port

- This flow generates pressure when met with system resistance

Flow and Pressure Relationship

Understanding the relationship between flow and pressure is crucial for proper Hydraulic pumps selection. Flow rate determines the speed of hydraulic actuators, while pressure determines the force they can exert.

Hydraulic pumps produce flow, and system resistance creates pressure. A pump's maximum pressure rating indicates the highest resistance it can overcome, while flow rate (typically measured in gallons per minute or liters per minute) determines how quickly fluid is moved.

The power output of Hydraulic pumps is calculated as the product of flow and pressure, making both parameters critical for matching pump performance to application requirements.

Hydraulic Pump Working Principles by Type

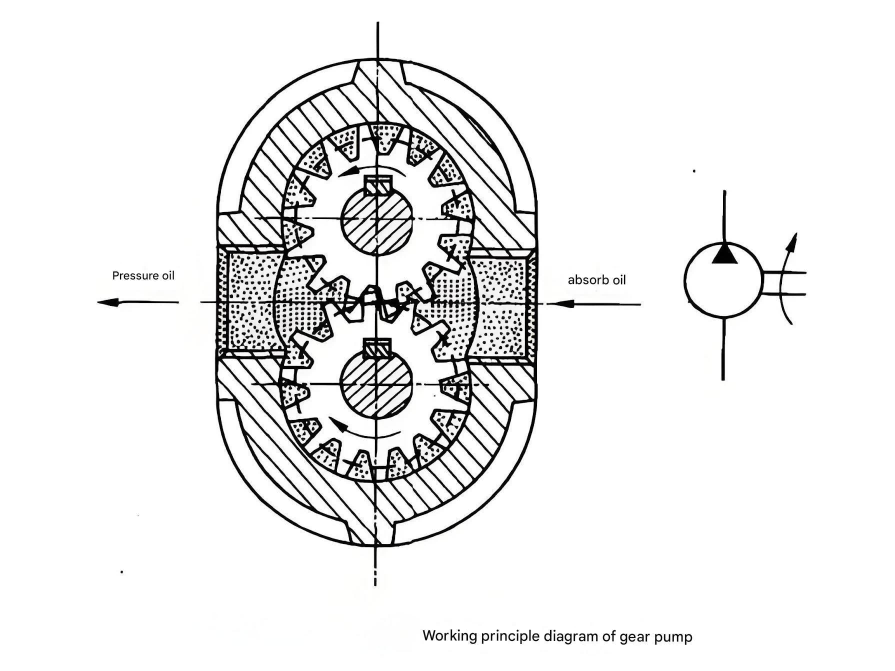

Gear Pump Operation

Gear pumps operate through the meshing of two gears within a housing. As the gears rotate, fluid is trapped between the gear teeth and the housing, carried around the circumference, and then forced out as the teeth mesh together.

This simple design creates a continuous flow, with flow rate determined by gear size, speed, and tooth geometry. Gear pumps are fixed displacement Hydraulic pumps, meaning they deliver a constant volume of fluid per revolution.

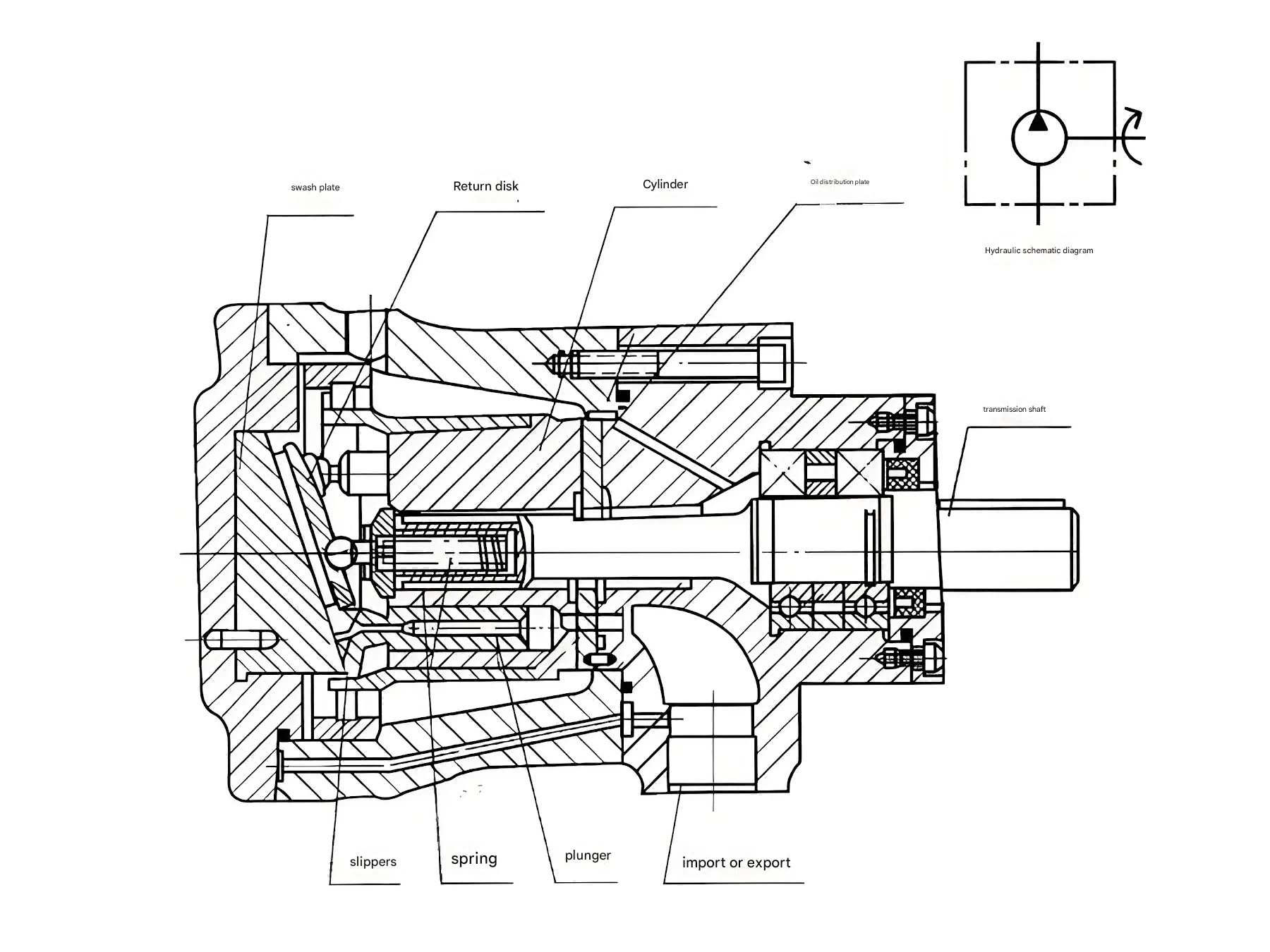

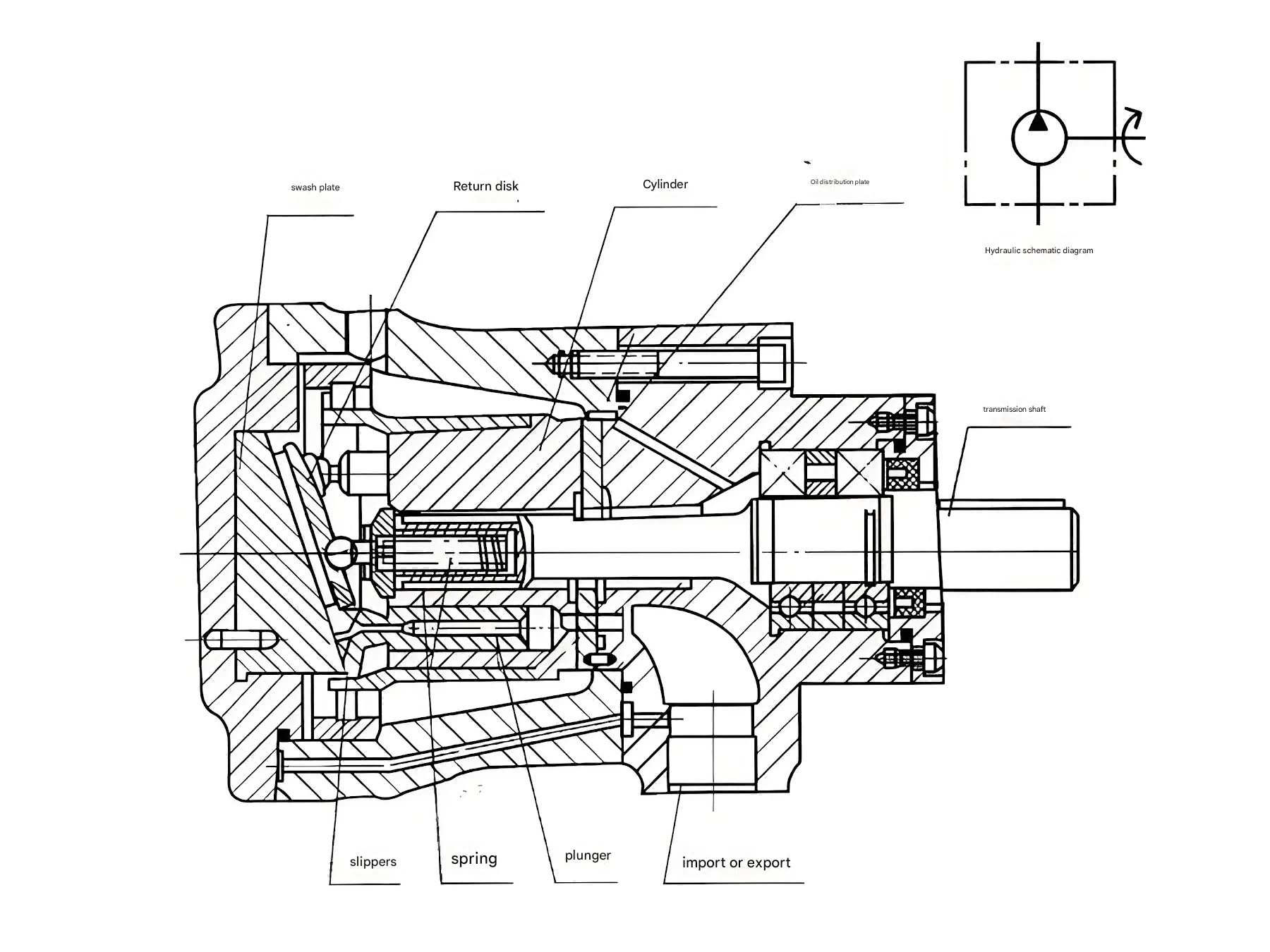

Piston Pump Operation

Piston pumps use reciprocating pistons within a rotating cylinder block. As the cylinder block rotates, pistons move in and out due to an angled swash plate or variable displacement mechanism.

This motion creates alternating vacuum and pressure in each cylinder, drawing fluid in during the intake stroke and forcing it out during the compression stroke. Many piston Hydraulic pumps feature variable displacement, allowing flow rate adjustment to match system demand.

Vane Pump Operation

Vane pumps feature a slotted rotor with rectangular vanes that slide in and out as the rotor spins off-center within the pump housing. Centrifugal force and/or spring pressure keep the vanes in contact with the housing.

As the rotor turns, the space between vanes expands at the inlet, drawing fluid in, then contracts at the outlet, forcing fluid out under pressure. This design provides smooth flow with minimal pulsation compared to some other Hydraulic pumps.

Hydraulic Pumps Manufacturing Process

The production of high-quality Hydraulic pumps requires precision engineering, advanced materials, and rigorous quality control. At Pozoom Hydraulic, we employ state-of-the-art manufacturing processes to ensure exceptional performance and durability.

Material Selection & Preparation

The manufacturing process begins with careful material selection based on the specific Hydraulic pumps design and performance requirements. Materials must withstand high pressures, resist wear, and maintain dimensional stability under varying temperatures.

Common materials include high-grade alloy steels for pump housings and internal components, cast iron for certain structural parts, and specialized coatings for wear resistance. All materials undergo rigorous testing for quality and consistency.

01

02

Heat Treatment

Critical components of Hydraulic pumps undergo specialized heat treatment processes to achieve the optimal balance of hardness, toughness, and wear resistance. This step is essential for withstanding the extreme pressures and mechanical stresses encountered in operation.

Processes include carburizing, quenching, tempering, and nitriding, each tailored to specific materials and component requirements. Strict temperature control and cooling rates ensure consistent material properties throughout each batch.

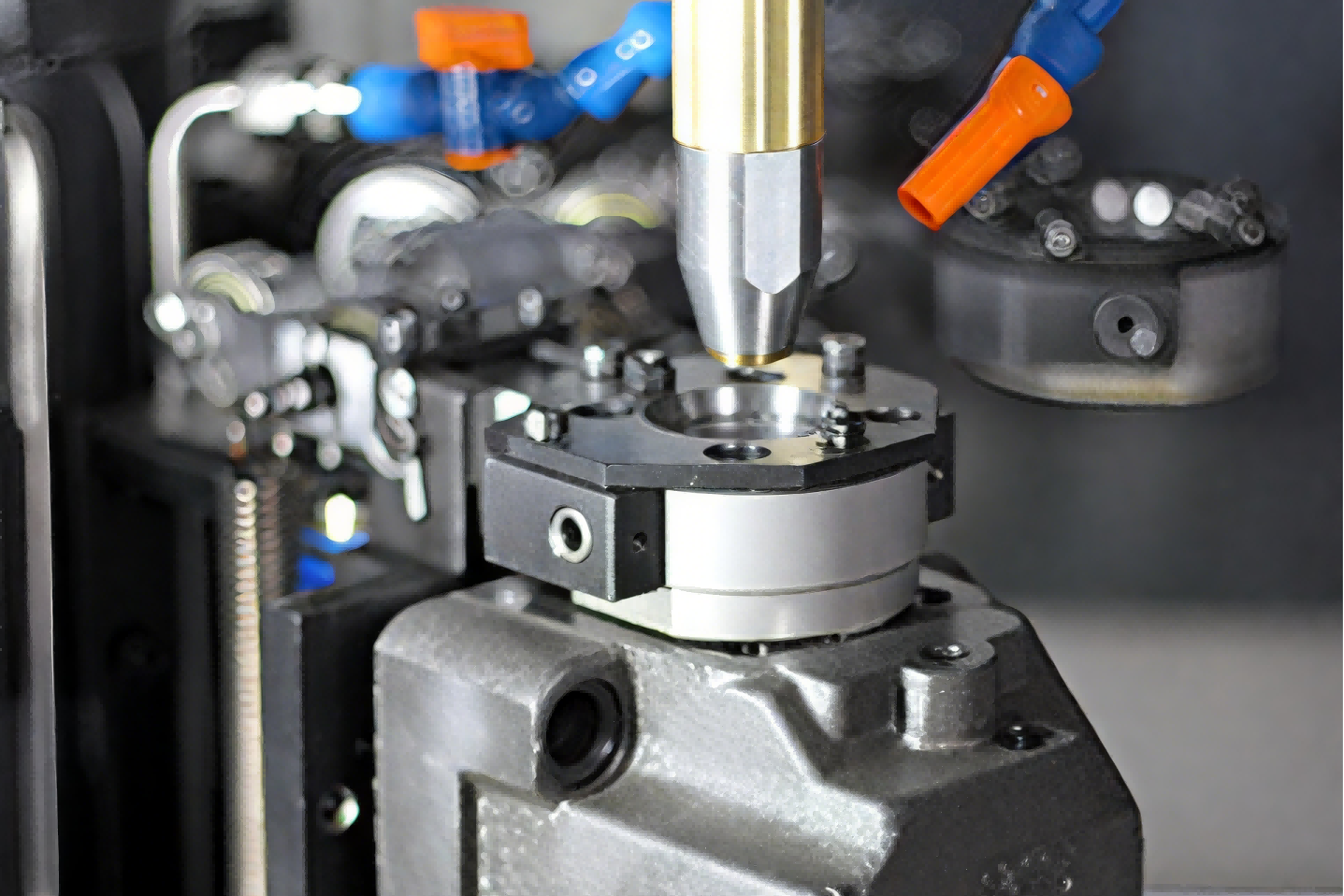

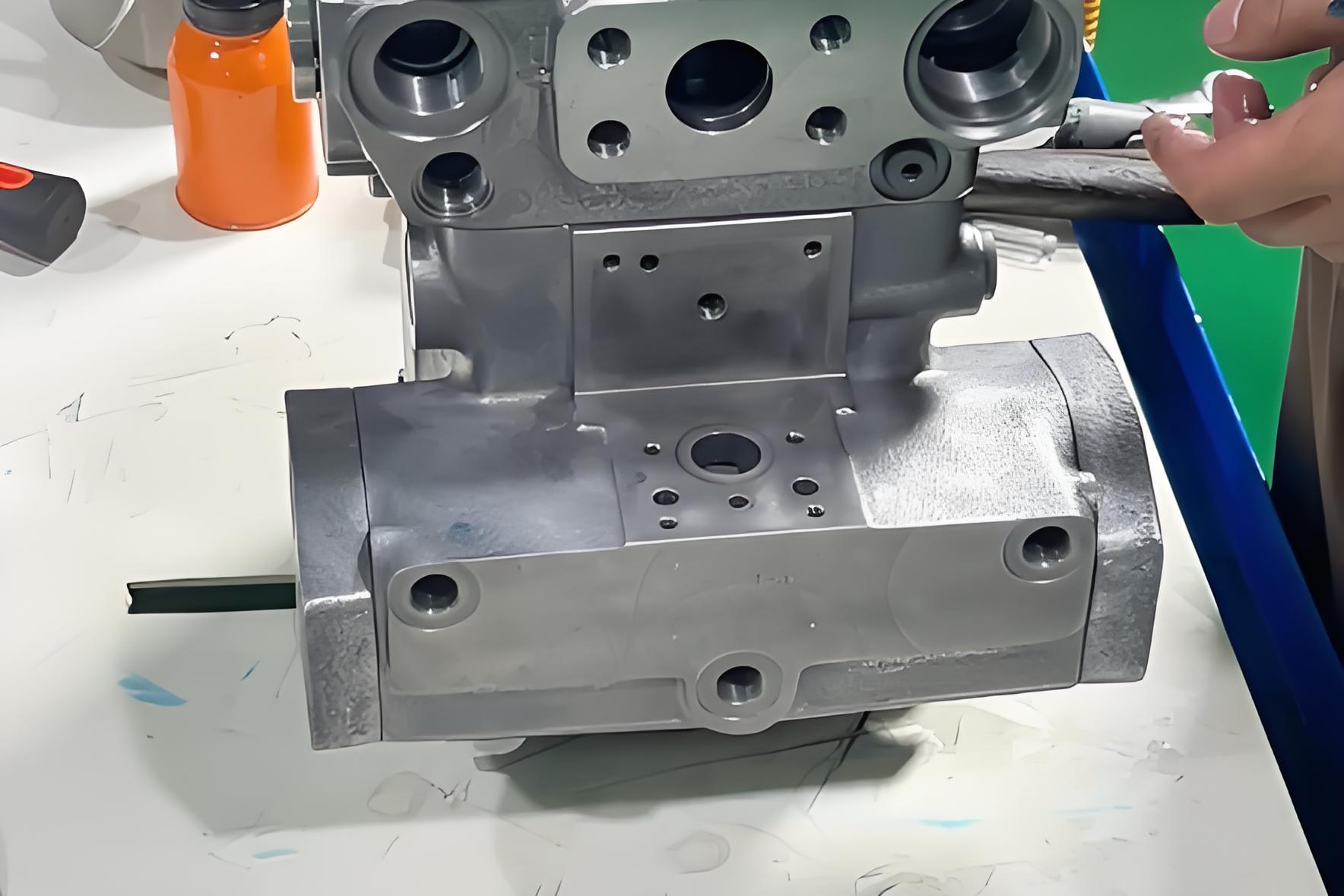

Precision Machining

Precision machining is critical for Hydraulic pumps performance, as even minute tolerances can affect efficiency and reliability. Computer Numerical Control (CNC) machines achieve the required precision, typically holding tolerances within 0.001mm.

Key processes include turning, milling, grinding, and honing of components like housings, rotors, gears, pistons, and vanes. Advanced multi-axis machining centers produce complex geometries with exceptional accuracy, ensuring proper fit and function of all parts.

03

04

Assembly

Hydraulic pumps assembly takes place in controlled environments to prevent contamination, which can severely impact performance and longevity. Skilled technicians, often assisted by automated systems, carefully fit precision components together.

Torque-controlled fastening ensures proper sealing and component alignment. Critical assembly steps include installing bearings, seals, and internal components with exacting precision. Cleanroom conditions may be used for high-performance Hydraulic pumps to ensure absolute cleanliness.

Testing & Quality Control

Every Hydraulic pump undergoes rigorous testing before leaving the factory. Testing protocols include pressure testing, flow rate measurement, efficiency analysis, noise level assessment, and leakage detection.

Advanced test benches simulate real-world operating conditions, cycling pumps through various pressure and flow scenarios. Statistical process control monitors key performance indicators, ensuring consistency across production runs. Any pumps failing to meet strict specifications are rejected or reworked.

05

Advanced Manufacturing Technologies

3D Printing

Additive manufacturing techniques create complex components with internal geometries that would be impossible with traditional machining. This technology enables lighter, more efficient Hydraulic pumps designs and rapid prototyping.

Smart Manufacturing

Industry 4.0 technologies, including IoT sensors and data analytics, monitor production processes in real-time. This ensures consistent quality in Hydraulic pumps manufacturing and enables predictive maintenance of production equipment.

Automated Inspection

Machine vision systems and laser scanning perform dimensional checks with micron-level precision. This automated inspection ensures every component meets exact specifications, critical for reliable Hydraulic pumps performance.

Hydraulic Pumps Applications

Hydraulic pumps power essential machinery across virtually every industry, delivering the power, precision, and reliability needed for critical operations. Pozoom Hydraulic provides tailored solutions for diverse application requirements.

Construction

Hydraulic pumps power excavators, bulldozers, cranes, and concrete pumps, providing the immense force needed for lifting, digging, and material handling in construction applications.

High pressure

Heavy duty

Variable flow

Agriculture

Agricultural machinery relies on Hydraulic pumps for functions like raising and lowering implements, steering, and powering attachments on tractors, harvesters, and irrigation systems.

Reliable

Low maintenance

Dust resistant

Manufacturing

In manufacturing, Hydraulic pumps power presses, injection molding machines, material handling systems, and robotic equipment, providing precise control and repeatable performance.

Precision control

High efficiency

Continuous operation

Mining

Mining operations depend on rugged Hydraulic pumps for heavy equipment like loaders, haul trucks, and drilling machinery, operating under extreme conditions with high reliability requirements.

Extreme duty

Abrasion resistant

High pressure

Aerospace

Aerospace applications utilize specialized Hydraulic pumps for flight control systems, landing gear, and cargo handling, requiring lightweight designs with exceptional reliability and performance.

Lightweight

High reliability

Precision

Marine

Marine applications use corrosion-resistant Hydraulic pumps for steering systems, winches, cranes, and hatch operations, designed to withstand harsh saltwater environments.

Corrosion resistant

Shock resistant

Reliable

Case Study: Hydraulic Pumps in Heavy Construction

Challenge

A major construction company was experiencing frequent failures with standard Hydraulic pumps in their large excavators operating in a demanding mining construction project. The extreme dust, temperature variations, and continuous heavy loading were causing premature pump wear and system downtime.

Solution

Pozoom Hydraulic engineers collaborated with the client to develop a customized piston pump solution with enhanced filtration, specialized bearing systems, and hardened internal components. The modified Hydraulic pumps featured improved cooling passages and dust-resistant seals specifically designed for the harsh environment.

Results

- 300% increase in pump service life

- 92% reduction in unplanned downtime

- 15% improvement in overall system efficiency

- Significant reduction in maintenance costs

Hydraulic Pumps Maintenance & Troubleshooting

Proper maintenance is essential for maximizing the lifespan and performance of Hydraulic pumps. Regular inspection and preventive maintenance can prevent costly downtime and extend pump service life significantly.

Preventive Maintenance Schedule

Daily Inspections

- Check fluid levels and condition

- Inspect for leaks around pump connections

- Monitor operating temperature

- Listen for unusual noises

- Check pressure gauge readings

Weekly Maintenance

- Inspect and clean suction strainers

- Check for loose mounting bolts

- Verify proper alignment between pump and drive

- Check for oil contamination using test kits

Monthly Maintenance

- Replace return line filters

- Test pump performance against specifications

- Inspect shaft seals for wear

- Check for excessive vibration

Annual Maintenance

- Complete fluid analysis and replacement

- Inspect internal components for wear

- Replace worn bearings and seals

- Calibrate pressure relief valves

- Perform pump efficiency testing

Common Issues & Troubleshooting

Excessive Noise

Possible causes and solutions:

- Low fluid level: Check reservoir and refill to proper level

- Air in system: Bleed air from system and check for suction leaks

- Clogged filter: Replace filter element

- Misalignment: Realign pump and drive

- Worn bearings: Replace bearings

Low Pressure

Possible causes and solutions:

- Relief valve stuck open: Clean or replace relief valve

- Internal leakage: Inspect and replace worn components

- Worn pump elements: Repair or replace worn parts

- Suction line restriction: Check and clear restrictions

Overheating

Possible causes and solutions:

- Low fluid level: Add fluid to proper level

- Contaminated fluid: Replace fluid and clean system

- Cooling system failure: Repair or replace cooler

- Excessive load: Reduce load or upgrade pump capacity

- Internal leakage: Repair worn components

Leakage

Possible causes and solutions:

- Loose fittings: Tighten to proper torque specification

- Worn seals: Replace shaft seals and O-rings

- Cracked housing: Replace pump housing

- Excessive pressure: Adjust pressure to recommended levels

Hydraulic Fluid Maintenance

Proper hydraulic fluid maintenance is critical for Hydraulic pumps performance and longevity. The fluid serves as a lubricant, heat transfer medium, and power transmission medium, making its condition essential to system health.

Fluid Selection Criteria

- Viscosity: Must match pump requirements for operating temperature range

- VI Index: High viscosity index for stability across temperature variations

- Additive Package: Contains anti-wear, anti-oxidation, and anti-foaming additives

- Compatibility: Compatible with pump materials and seals

- Operating Environment: Special formulations for extreme temperatures or contamination risks

Fluid Contamination Control

Contamination is the leading cause of Hydraulic pumps failure. Even microscopic particles can cause significant wear to precision components.

Contamination Sources

Manufacturing residue

Ingress during maintenance

Atmospheric dust

Internal wear particles

Water condensation

Cross-contamination

Prevention Methods

- High-efficiency filtration systems (Beta ≥ 200)

- Desiccant breathers on reservoirs

- Proper fluid handling procedures

- Regular fluid analysis testing

The Impact of Proper Maintenance on Hydraulic Pumps Lifespan

Data shows that proper maintenance can extend Hydraulic pumps service life by up to 300% compared to minimal or reactive maintenance approaches.