Menu

Understanding Hydraulic Spare Parts

A comprehensive guide to the components, manufacturing, and engineering principles behind hydraulic systems

Introduction to Hydraulic Systems

Hydraulic systems are integral to countless industrial applications, providing power transmission through the use of pressurized fluid. At the heart of these systems lies a complex network of components working in harmony to convert mechanical energy into fluid energy and back again. The reliability and efficiency of any hydraulic system depend heavily on the quality and precision of its individual parts, collectively known as hydraulic spare parts.

Learn the fundamentals, manufacturing processes, and technical considerations of hydraulic spare parts. From the largest component to the smallest seal, every part plays a vital role in the overall performance and life of hydraulic systems in a variety of industries, including construction, agriculture, manufacturing, and aerospace.

Understanding the engineering behind hydraulic spare parts provides valuable insight into system maintenance, troubleshooting, and optimization. This knowledge helps technicians, engineers, and enthusiasts alike make informed decisions about component selection, installation, and care.

Fundamental Principles of Hydraulics

Pascal's Law and Hydraulic Power

All hydraulic systems operate on Pascal's Law, which states that pressure exerted anywhere in a confined incompressible fluid is transmitted equally in all directions throughout the fluid. This principle enables the multiplication of force, allowing hydraulic systems to generate significant power relative to their size.

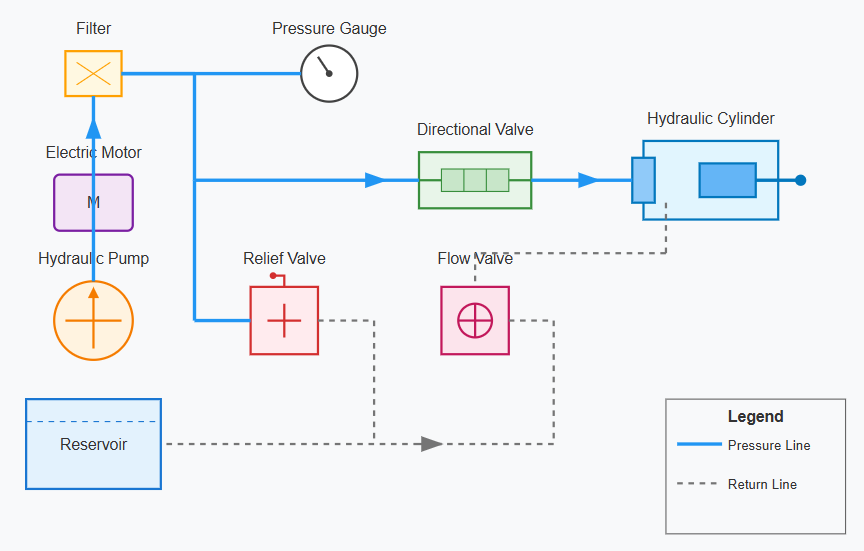

The basic hydraulic circuit consists of a pump that creates flow, valves that control direction and pressure, actuators that convert fluid energy back to mechanical energy, and the hydraulic spare parts that connect and seal these components. The efficiency of this energy transfer depends on precise tolerances and proper material selection in all hydraulic spare parts.

Fluid Dynamics in Hydraulic Systems

Fluid dynamics plays a crucial role in hydraulic system performance. Factors such as flow rate, pressure drop, and fluid viscosity directly impact how hydraulic spare parts function together. The design of components must account for laminar and turbulent flow conditions to minimize energy loss and maximize efficiency.

Temperature also significantly affects hydraulic fluid properties, influencing the selection of materials for seals and other hydraulic spare parts. Understanding these thermal dynamics is essential for designing systems that operate reliably across various environmental conditions.

Main Movement Components

The main movement components form the operational core of hydraulic systems, responsible for converting energy and facilitating motion. These hydraulic spare parts must withstand significant forces, pressures, and wear while maintaining precise operation.

Cylinder Block Assembly

The cylinder block assembly serves as the housing for pistons in hydraulic pumps and motors, forming the primary pressure chamber.

- High-precision machined blocks

- Integral port designs

- Hardened internal surfaces

Piston

Pistons convert fluid pressure into linear motion, moving within the cylinder block to create flow or pressure.

- Plunger pistons

- Barrel pistons

- Coated precision pistons

- Hollow pistons

Swash Plate Assembly

The swash plate assembly controls piston stroke length in axial piston pumps and motors, regulating flow output.

- Variable angle plates

- Fixed displacement plates

- Bearing-supported designs

- Wear-resistant coatings

Main Shaft

Transmitting rotational power through the hydraulic system, the main shaft connects prime movers to hydraulic pumps or motors.

- Keyed shafts

- Spline shafts

- Hollow through-shafts

- Hardened and ground shafts

Drive Shaft

The drive shaft transfers power between components, often connecting the main shaft to other system elements.

- Cardan shafts

- Telescoping drive shafts

- Flanged drive shafts

- Quick-disconnect shafts

Universal Joint

Allowing angular misalignment between connected shafts, universal joints accommodate movement while transmitting torque.

- Single u-joints

- Double cardan joints

- Constant velocity joints

- High-angle universal joints

Distribution and Control Systems

These components manage the flow and direction of hydraulic fluid within the system, ensuring precise control and operation of all hydraulic functions.

Valve Plate

Directs fluid flow between the pump inlet and outlet ports while preventing backflow and ensuring efficient operation.

- Hydraulically balanced designs

- Hardened surface plates

- Pattern-optimized porting

- Anti-cavitation features

Port Plate

Manages fluid distribution between the cylinder block and system lines in axial piston pumps and motors.

- Pressure-balanced port plates

- Wear-resistant materials

- Precision-machined sealing surfaces

- Directional control plates

Pump Housing

Encloses and protects internal components while providing mounting points and fluid passageways.

- Cast iron housings

- Aluminum alloy casings

- Integral cooling fins

- Flanged mounting designs

Bearing and Support Systems

These components provide structural support and reduce friction between moving parts, ensuring smooth operation and extended service life.

Tapered Roller Bearings

Handle both radial and axial loads efficiently, ideal for high-pressure hydraulic applications.

Ball Bearings

Provide low friction operation for high-speed rotational components with primarily radial loads.

Thrust Bearings

Designed specifically to handle axial loads, maintaining proper spacing between components.

Bearing Races

Hardened outer and inner rings that guide rolling elements while distributing loads evenly.

Bearing Housings

Provide secure mounting and alignment for bearings while absorbing and distributing forces.

Thrust Plates

Distribute axial forces across bearing surfaces, preventing premature wear in high-pressure areas.

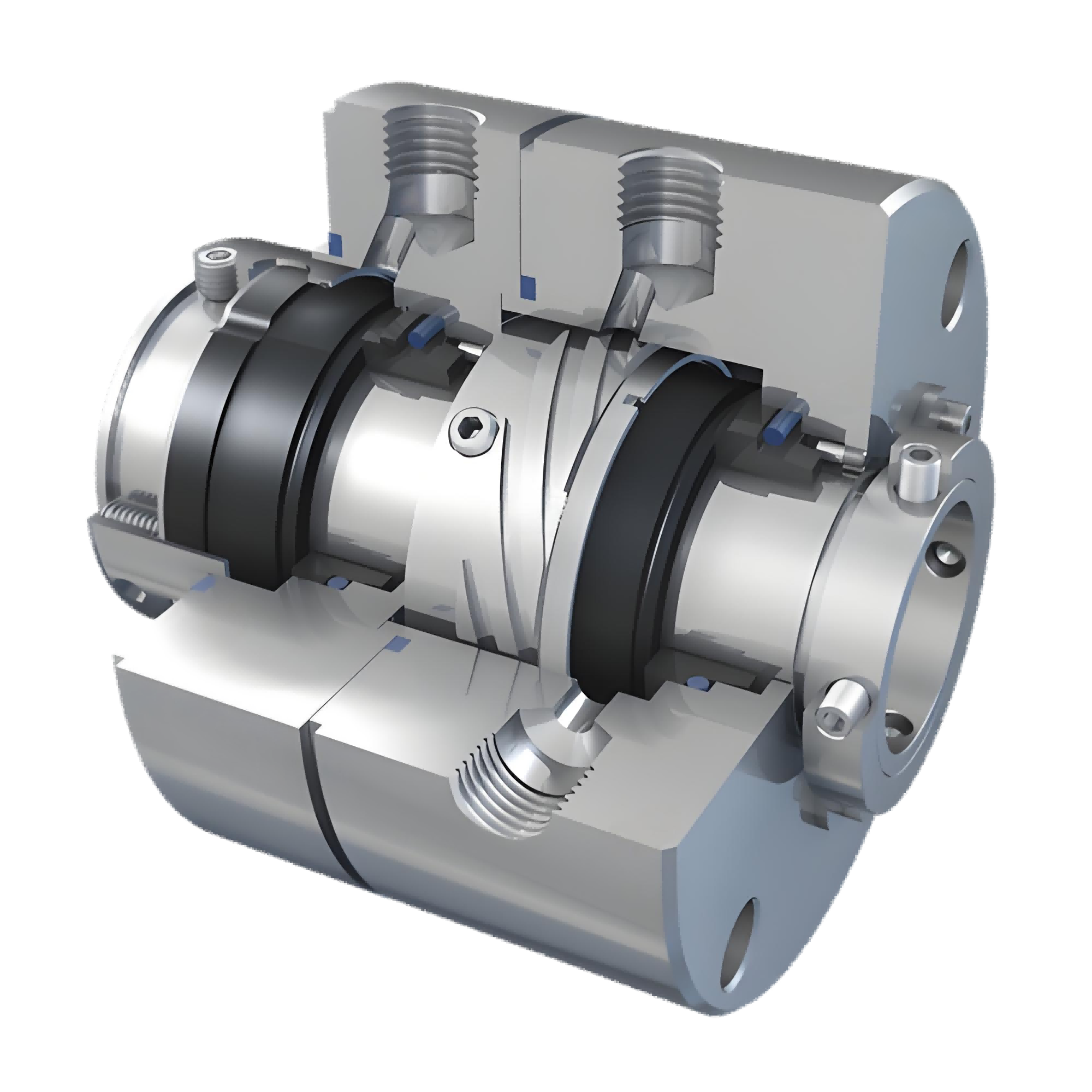

Sealing Systems

These critical components prevent fluid leakage, maintain system pressure, and protect internal parts from contamination.

O-Rings

Elastic circular seals used in static and dynamic applications to prevent fluid leakage between mating surfaces.

- Nitrile (NBR) compounds

- Viton (FKM) for high temperatures

- PTFE encapsulated o-rings

- Metric and imperial sizes

Various Seals

Specialized sealing components designed for specific applications and pressure conditions.

- Piston seals and wipers

- Rod seals and scrapers

- Gasket sets and kits

- U-cups and V-packings

- Back-up rings and anti-extrusion rings

Connection and Fastening Components

These components secure and connect various parts of the hydraulic system, ensuring structural integrity and proper alignment.

Connecting Rod Assemblies

Link moving components, transmitting force while allowing pivotal movement between parts.

Adjusting Bolts

Precision fasteners used to set and maintain critical clearances and positions within assemblies.

Long Bolts

High-strength fasteners for securing large components or assemblies requiring through-bolting.

Retaining Ring Sets

Circular fasteners that secure components on shafts or in bores without threading.

Gaskets/Washers

Flat components that seal joints or distribute fastener loads across surfaces.

Auxiliary Movement Components

These supporting components enhance system performance, reduce wear, and ensure proper operation of primary hydraulic elements.

Copper Shoes

Wear-resistant sliding components that reduce friction between moving parts, often used with pistons.

Piston Guides

Precision components that maintain proper alignment of pistons within cylinder bores during operation.

Spring Sets

Elastic components that provide restoring force, maintain contact between parts, or control pressure.

- Return springs

- Pressure springs

- Wave springs

- Disc spring assemblies

Manufacturing Processes for Hydraulic Spare Parts

The production of hydraulic spare parts demands exceptional precision and consistency to ensure proper functionality under extreme conditions. Manufacturers employ various advanced techniques to create components that meet strict tolerances, material specifications, and performance requirements.

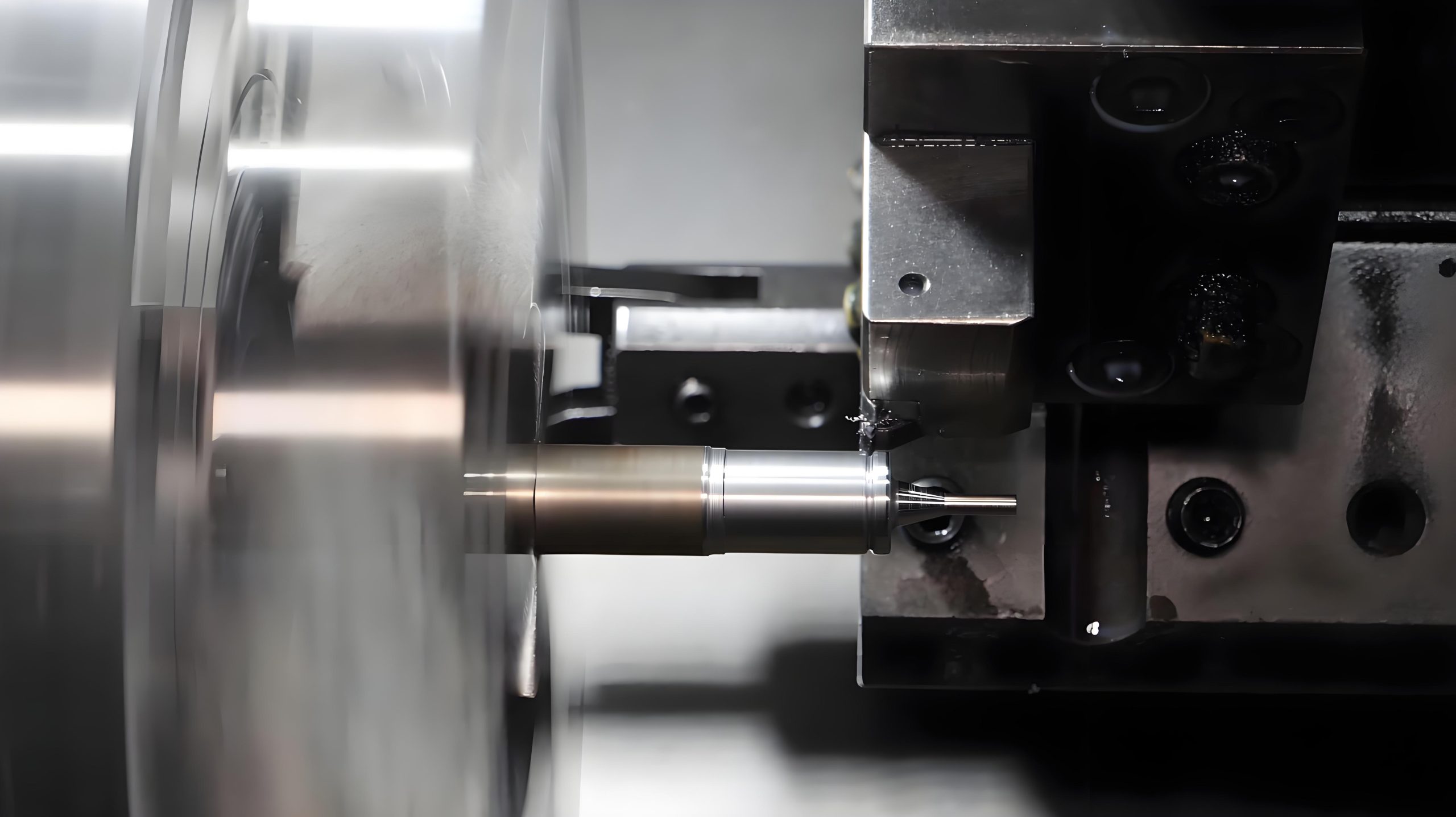

Precision Machining

Computer Numerical Control (CNC) machining forms the backbone of hydraulic spare parts manufacturing. CNC turning centers produce cylindrical components like shafts and pistons with diameters held to tolerances as tight as ±0.001mm. Milling operations create complex shapes in valve bodies and pump housings, ensuring precise mating surfaces.

Grinding processes further refine critical surfaces, achieving mirror-like finishes that reduce friction and improve sealing capabilities. These precision techniques ensure that hydraulic spare parts fit together perfectly, minimizing leakage and maximizing efficiency.

Heat Treatment

Many hydraulic spare parts undergo heat treatment to enhance mechanical properties. Processes like carburizing, quenching, and tempering create hard, wear-resistant surfaces while maintaining tough cores in components like gears and shafts. This balance prevents premature failure under cyclic loading and contact stresses.

Surface Coating

Various coating technologies improve the performance of hydraulic spare parts. Chrome plating provides corrosion resistance and a low-friction surface for pistons and rods. Thermal spray coatings apply wear-resistant materials to critical surfaces, extending component life in abrasive environments.

Assembly and Testing

Final assembly of hydraulic spare parts involves careful cleaning and inspection to prevent contamination. Testing procedures verify pressure resistance, flow characteristics, and leakage rates. Advanced systems use computerized testing to simulate operating conditions and ensure performance meets specifications.

Material Selection for Hydraulic Spare Parts

The choice of materials significantly impacts the performance and durability of hydraulic spare parts. Carbon and alloy steels form the foundation for structural components requiring strength and toughness. Stainless steels provide corrosion resistance in harsh environments, while aluminum alloys offer lightweight alternatives for specific applications.

For specialized applications, manufacturers may use high-performance materials such as titanium alloys for weight-sensitive aerospace components or nickel-based superalloys for extreme temperature environments. The selection process balances factors including strength, wear resistance, corrosion resistance, and cost to create optimal hydraulic spare parts for each application.

Valve and Control Systems

Valve and control systems regulate the flow, pressure, and direction of hydraulic fluid within a system, ensuring precise operation and safety. These hydraulic spare parts act as the "brain" of the hydraulic system, directing power where it's needed and preventing overload conditions.

Valve Plate

The valve plate controls fluid distribution between the inlet and outlet ports in hydraulic pumps and motors. This critical hydraulic spare part ensures proper timing of fluid flow into and out of piston chambers, maximizing efficiency and minimizing pressure fluctuations.

Manifold Block

Serving as a central hub for fluid distribution, the manifold block contains internal passages that direct flow between components. This hydraulic spare part simplifies system design by eliminating multiple hoses and fittings, reducing potential leakage points.

Pump Housing

The pump housing encloses and protects internal components while providing mounting points for other system elements. This robust hydraulic spare part must withstand system pressure while maintaining precise alignment of internal moving parts.

Control Principles in Hydraulic Systems

Hydraulic control systems operate on feedback principles, using sensors and valves to maintain desired operating parameters. Pressure-compensated flow control valves automatically adjust to maintain constant flow regardless of pressure changes, ensuring consistent actuator speed.

Modern systems increasingly incorporate electronic controls with proportional valves, allowing for precise adjustment and integration with computerized systems. These advanced hydraulic spare parts enable programmable motion profiles, remote monitoring, and adaptive control strategies that optimize performance across varying operating conditions.

Bearing and Support Systems

Bearing and support systems play a critical role in maintaining alignment, reducing friction, and absorbing loads in hydraulic machinery. These hydraulic spare parts ensure smooth operation while protecting components from excessive wear and premature failure.

Tapered Roller Bearings

These hydraulic spare parts handle both radial and axial loads, providing high capacity in a compact design. Their conical rollers and races distribute loads evenly, making them ideal for applications with combined forces.

Ball Bearings

Offering low friction and high precision, ball bearings are common hydraulic spare parts for high-speed applications. Their point contact design minimizes friction while accommodating moderate radial and axial loads.

Thrust Bearings

Designed specifically to handle axial loads, thrust bearings are essential hydraulic spare parts in applications where components experience significant end-to-end forces, such as in axial piston pumps.

Bearing Races

These precision-machined hydraulic spare parts provide smooth surfaces for bearing elements to roll against. Properly hardened and ground races ensure even load distribution and long bearing life.

Bearing Housings

These structural hydraulic spare parts position and secure bearings within the system, maintaining proper alignment and supporting applied loads. They often incorporate lubrication passages and seals.

Thrust Plates

Thrust plates absorb axial forces in rotating assemblies, protecting other hydraulic spare parts from excessive wear. They often work in conjunction with thrust bearings to distribute loads over larger surfaces.

Bearing Technology and Lubrication

Proper lubrication is critical for maximizing the service life of bearing hydraulic spare parts. Most hydraulic systems use the hydraulic fluid itself for bearing lubrication, requiring careful consideration of viscosity, additive packages, and filtration.

Modern bearing designs for hydraulic applications often incorporate cage structures that optimize lubricant flow while maintaining proper spacing between rolling elements. Sealed bearing units provide maintenance-free operation in contaminated environments, protecting internal components from debris that could accelerate wear.

Sealing Systems

Sealing systems are essential for maintaining pressure, preventing fluid leakage, and protecting hydraulic components from contamination. These hydraulic spare parts must function reliably across wide ranges of pressure, temperature, and fluid types while accommodating component movement.

O-Rings and Their Applications

O-rings are versatile hydraulic spare parts used in static and dynamic sealing applications. Their simple design—typically a circular cross-section elastomer ring—provides effective sealing through deformation under pressure, creating a barrier between surfaces.

The performance of O-rings depends on material selection, with various elastomers offering different resistance to temperature, chemicals, and wear. Common materials include nitrile rubber (NBR) for general applications, fluorocarbon (FKM) for high temperatures and chemical resistance, and ethylene propylene (EPDM) for excellent weathering resistance.

Proper groove design is critical for maximizing O-ring performance. The groove dimensions must allow sufficient compression to ensure a tight seal while preventing excessive deformation that could lead to extrusion or premature failure.

Other Critical Sealing Components

Beyond O-rings, various specialized hydraulic spare parts provide sealing solutions for specific applications. Piston seals prevent fluid leakage between the piston and cylinder bore in hydraulic actuators, typically using U-cup or V-ring designs that energize under pressure.

Rod seals prevent fluid leakage around the piston rod as it extends and retracts from the cylinder, combining a primary sealing element with a wiper to remove contaminants. Static seals, including gaskets and flat seals, provide reliable sealing between stationary components.

All these hydraulic spare parts must maintain their sealing properties throughout the system's operating range. Factors such as surface finish, installation technique, and compatibility with system fluids directly impact seal performance and service life.

Connection and Fastening Components

Connection and fastening components provide the structural integrity and fluid pathways that make hydraulic systems functional. These hydraulic spare parts must securely join components while maintaining pressure integrity and alignment.

Connecting Rod Assemblies

These hydraulic spare parts transmit motion between components in hydraulic pumps and motors, converting rotational motion to linear motion and vice versa. Precision manufacturing ensures proper alignment and minimizes dynamic imbalance.

Adjustment Bolts

Critical for setting clearances and preloads in hydraulic assemblies, these hydraulic spare parts allow fine-tuning of system parameters. They often feature locking mechanisms to maintain settings under vibration and thermal cycling.

Long Bolts

These high-strength hydraulic spare parts fasten major components together, such as pump housings and cylinder heads. They must maintain clamping force under pressure cycling and temperature variations to prevent leakage.

Snap Ring Assemblies

These retaining hydraulic spare parts secure components on shafts or in bores, providing a simple yet effective solution for axial positioning. They come in various designs including internal, external, and constant-section types to accommodate different applications.

Gaskets/Washers

These hydraulic spare parts provide sealing between flange connections and distribute clamping forces evenly. Gaskets are typically made from compressible materials that conform to surface irregularities, while washers protect surfaces and prevent fastener loosening.

Fastening Technology in Hydraulic Systems

The selection of appropriate fastening hydraulic spare parts involves consideration of multiple factors including clamping force requirements, vibration resistance, and environmental conditions. Hydraulic systems often utilize preload techniques to ensure joint integrity under pressure cycling.

Threaded fasteners for hydraulic applications typically feature fine threads to provide better vibration resistance and more precise adjustment. Many critical connections use thread-locking compounds or mechanical locking devices to prevent loosening during operation. Proper torque application is essential to achieve the correct preload without damaging threads or components.

Auxiliary Movement Components

Auxiliary movement components enhance the performance, reliability, and functionality of primary hydraulic system elements. These specialized hydraulic spare parts often operate in challenging conditions, requiring precise design and material selection.

Copper Shoe Plates

These hydraulic spare parts provide a low-friction interface between moving components, typically in axial piston pumps and motors. The copper material offers excellent thermal conductivity, helping dissipate heat generated by friction while maintaining a lubricating film under high pressures.

Piston Guides

Piston guides maintain proper alignment of pistons within their cylinders, preventing metal-to-metal contact and reducing wear. These hydraulic spare parts often incorporate bearing materials or coatings that minimize friction while withstanding lateral forces.

Spring Assemblies

Springs are versatile hydraulic spare parts used for various functions including returning components to their neutral position, maintaining contact between moving parts, and providing damping. They must deliver consistent force over millions of cycles while resisting fatigue and corrosion.

Design Considerations for Auxiliary Components

Auxiliary hydraulic spare parts often operate in environments with limited lubrication, high temperatures, and significant wear. Designers must carefully select materials that balance friction, wear resistance, and cost-effectiveness.

For example, copper shoe plates frequently use a combination of copper alloys with embedded lubricants to maintain performance under boundary lubrication conditions. Piston guides may incorporate self-lubricating materials or porous metal structures that retain lubricant for extended periods.

Spring design involves careful calculation of wire diameter, coil geometry, and material selection to achieve the required force characteristics while ensuring sufficient fatigue life. Many hydraulic spring assemblies use corrosion-resistant materials or coatings to withstand exposure to hydraulic fluids and environmental contaminants.

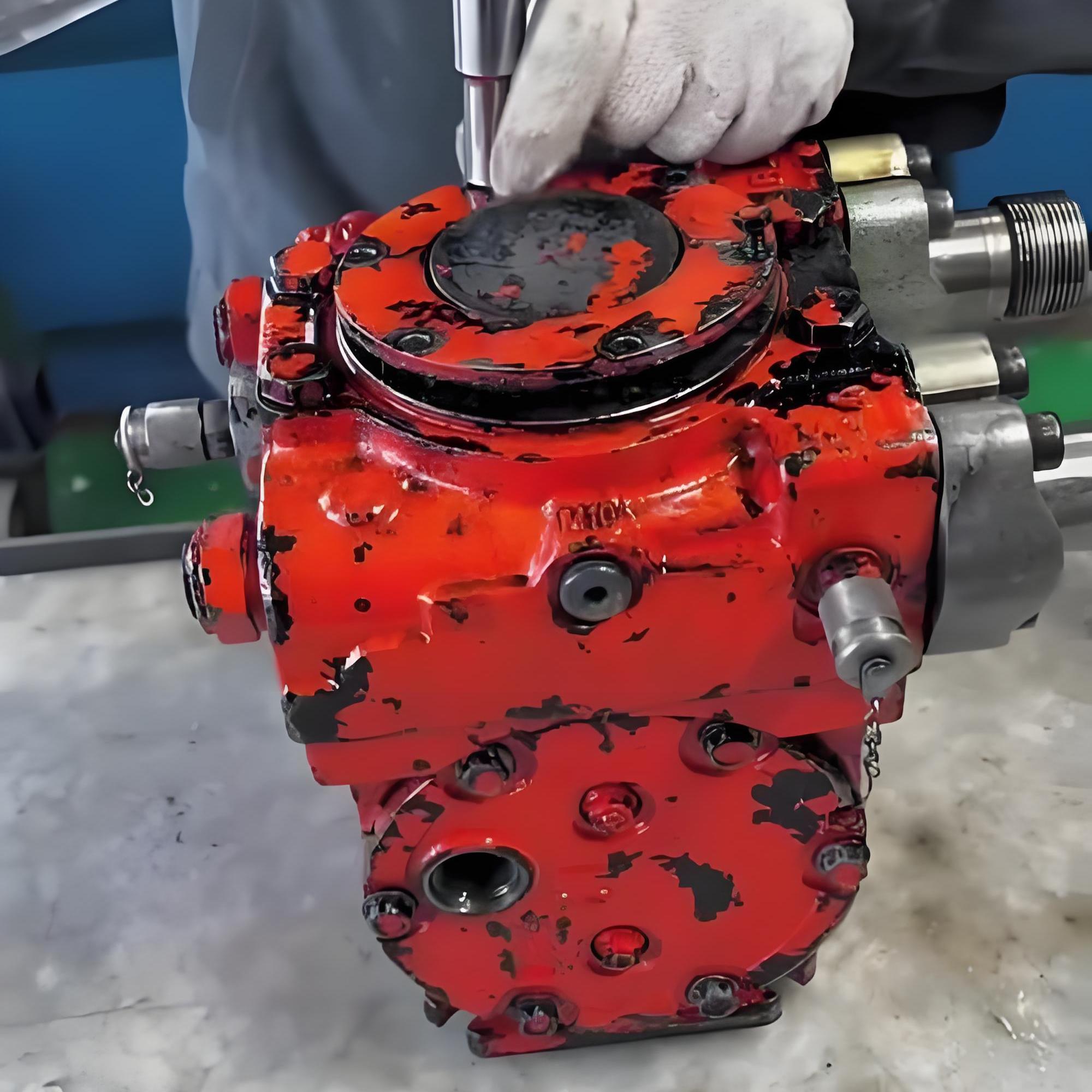

Maintenance and Troubleshooting of Hydraulic Spare Parts

Preventive Maintenance Practices

Proper maintenance extends the life of hydraulic spare parts and ensures system reliability. Regular inspection of seals and gaskets can identify potential leaks before they cause significant issues. Monitoring fluid condition through regular sampling helps detect contamination or degradation that could damage components.

Scheduled replacement of wear items such as bearings and seals prevents unexpected failures. When servicing hydraulic systems, proper cleaning procedures are essential to prevent contamination, as even small particles can cause premature wear of hydraulic spare parts.

Common Failure Modes and Analysis

Understanding why hydraulic spare parts fail is key to preventing future issues. Common failure modes include:

- Wear due to contamination or insufficient lubrication

- Corrosion from fluid incompatibility or moisture ingress

- Fatigue failure in springs and rotating components

- Seal degradation from temperature extremes or chemical incompatibility

- Overload failure from excessive pressure or torque

Failure analysis often involves examining wear patterns, measuring clearances, and testing fluid samples to identify root causes. This information can guide improvements in maintenance practices or component selection for specific applications.

Best Practices for Hydraulic Spare Parts Handling

Proper handling and storage of hydraulic spare parts prevent damage before installation. Components should be stored in clean, dry environments away from direct sunlight and temperature extremes. Seals and elastomeric parts require special care, including protection from ozone sources and compatibility with storage materials.

When installing new hydraulic spare parts, technicians should follow proper procedures including cleaning mating surfaces, using correct torque values, and ensuring proper alignment. Improper installation is a leading cause of premature component failure, even with high-quality parts.

Future Developments in Hydraulic Spare Parts

The hydraulic industry continues to evolve, driven by demands for greater efficiency, durability, and environmental responsibility. These trends are shaping the development of next-generation hydraulic spare parts with enhanced performance characteristics.

Advanced Materials

New materials are being developed for hydraulic spare parts, including high-strength composites that reduce weight while maintaining performance. Advanced ceramics offer superior wear resistance in high-pressure applications, while nanocomposite materials provide enhanced tribological properties.

Smart Components

The integration of sensors into hydraulic spare parts enables condition monitoring and predictive maintenance. Smart bearings can detect wear and temperature changes, while intelligent seals monitor leakage and degradation, providing real-time data to optimize maintenance schedules.

Sustainable Technologies

Environmental concerns are driving the development of more sustainable hydraulic spare parts. This includes biodegradable seal materials, recycled metal components, and manufacturing processes that minimize energy consumption and waste generation.

Digitalization and Hydraulic Component Design

Advanced simulation tools are revolutionizing the design of hydraulic spare parts. Finite element analysis (FEA) allows engineers to optimize component shapes for strength and weight, while computational fluid dynamics (CFD) models fluid flow through valves and passages to minimize pressure losses.

Additive manufacturing, or 3D printing, is enabling the production of complex hydraulic spare parts with internal geometries that would be impossible with traditional manufacturing methods. This technology allows for topology optimization, creating components that use material only where necessary, reducing weight and improving performance.

Hydraulic spare parts form the building blocks of reliable, efficient hydraulic systems that power modern industry. From the precision-machined main components to the smallest seals and fasteners, each part plays a vital role in system performance.

Understanding the design principles, manufacturing processes, and material science behind these components provides valuable insight into hydraulic system operation and maintenance. This knowledge helps ensure proper selection, installation, and care of hydraulic spare parts, maximizing system uptime and reducing lifecycle costs.

As technology advances, hydraulic spare parts will continue to evolve, incorporating new materials, smart technologies, and sustainable manufacturing practices. These innovations will further enhance the performance, efficiency, and environmental compatibility of hydraulic systems across countless applications.