Menu

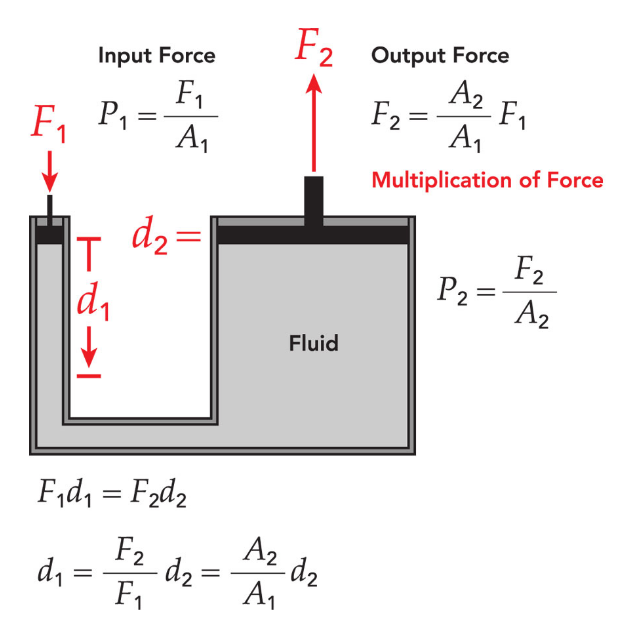

Compared with mechanical transmission, hydraulic transmission has many advantages, therefore, hydraulic transmission is widely used in mechanical engineering. With the development of hydraulic transmission technology, it has become an indispensable part of modern mechanical engineering. Hydraulic transmission is a form of transmission that uses liquid as the working medium to transfer energy. Through energy conversion devices (such as hydraulic pumps), it converts the mechanical energy of the prime mover (such as an electric motor) into the pressure energy of the liquid, and then through closed pipelines, control elements, etc., another energy device (such as hydraulic cylinders, hydraulic motors) converts the pressure energy of the liquid into mechanical energy to drive the load and achieve the linear or rotary motion required by the actuator. This working principle and composition form the foundation of hydraulic transmission systems, which are represented by standardized graphic symbols in engineering drawings for clear communication and design purposes. The advantages and disadvantages of hydraulic transmission determine its wide range of applications in various fields of mechanical engineering.