Menu

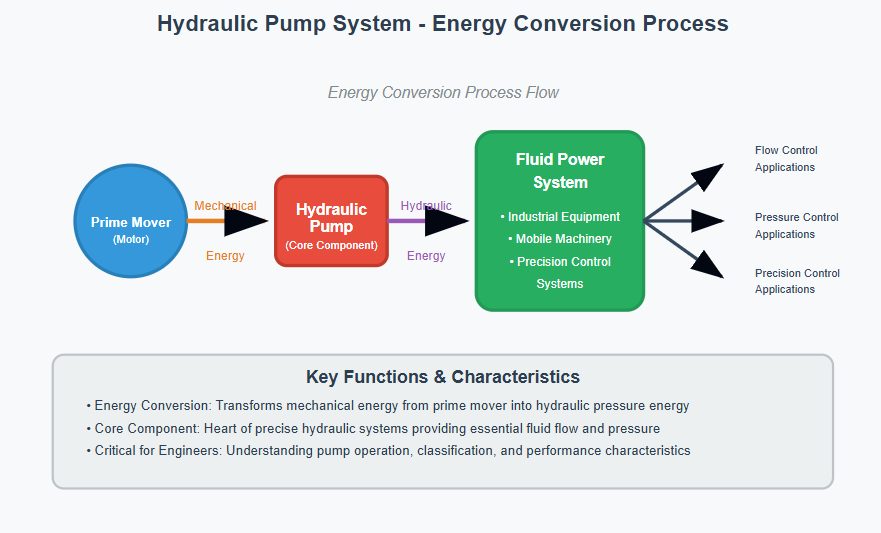

Hydraulics pumps are essential energy conversion devices that transform mechanical energy from prime movers (typically electric motors) into hydraulic pressure energy within fluid power systems. These sophisticated machines serve as the heart of hydraulic systems, providing the necessary flow and pressure to operate various industrial equipment, mobile machinery, and precision control systems.

Understanding the working principles, classifications, and performance characteristics of hydraulics pumps is crucial for engineers and technicians working in fluid power applications.

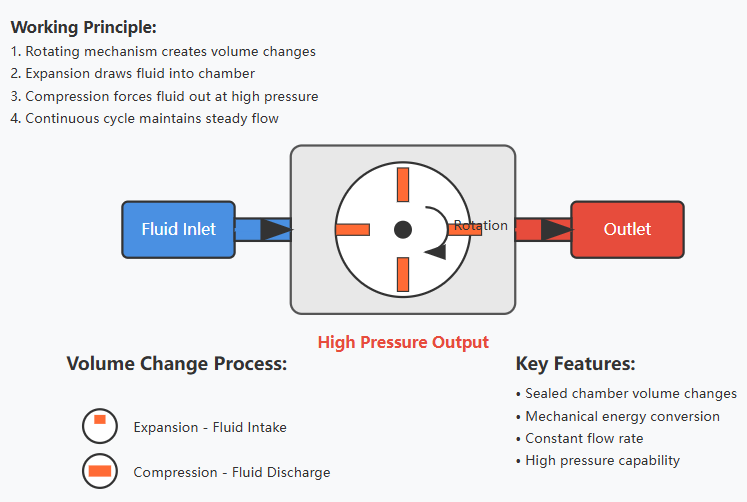

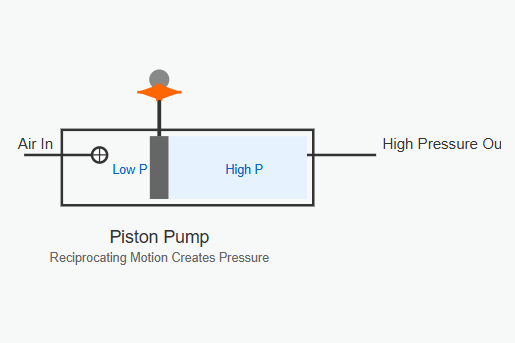

The fundamental operation of hydraulics pumps relies on the positive displacement principle, where sealed working chambers undergo cyclic volume changes to create fluid flow. When cam 1 rotates, plunger 2 moves reciprocally within cylinder body 4 under the combined action of the cam and spring 3. During rightward plunger movement, the oil chamber volume increases, creating a vacuum that draws fluid through suction valve 5. Conversely, leftward plunger movement decreases chamber volume, forcing the trapped fluid through discharge valve 6 into the system.

This volumetric principle demonstrates that hydraulics pumps operate through controlled volume variations in sealed working chambers, with output flow rate determined by the magnitude of these volume changes. The relationship between mechanical input and hydraulic output defines the energy conversion efficiency of these devices.

Hydraulic motors operate on the reverse principle, converting hydraulic pressure energy back into mechanical rotational energy. When pressurized fluid enters a positive displacement pump, it can drive the shaft rotation, effectively functioning as a hydraulic motor. While most positive displacement hydraulics pumps can theoretically operate as motors, practical implementations often require structural modifications to optimize performance in each mode of operation.

The classification of hydraulics pumps follows two primary criteria: displacement adjustability and structural design. Each classification offers distinct advantages for specific applications and operating conditions.

Deliver a constant volume per revolution, providing consistent flow output proportional to rotational speed. These pumps offer simplicity, reliability, and lower cost for applications with stable flow requirements.

Allow adjustment of output volume through mechanical or hydraulic controls, enabling flow regulation without changing rotational speed. This flexibility improves energy efficiency in systems with varying flow demands.

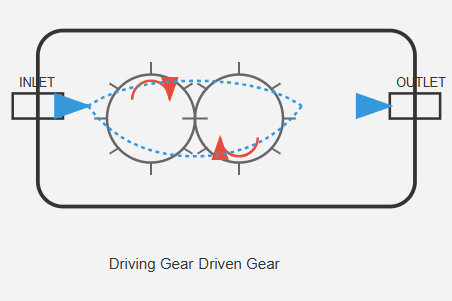

Simple, robust construction ideal for moderate pressure applications with good tolerance for contamination.

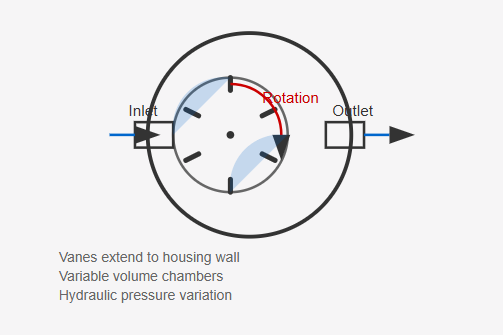

Offer smooth flow characteristics and moderate efficiency with better performance at higher speeds.

Achieve the highest pressures and efficiencies, suitable for demanding industrial and mobile applications.

Simple design with two meshing gears that displace fluid through the pump housing.

Utilize sliding vanes in a rotor to create variable volume chambers during rotation.

Employ reciprocating pistons in a cylinder block to generate flow with high pressure capability.

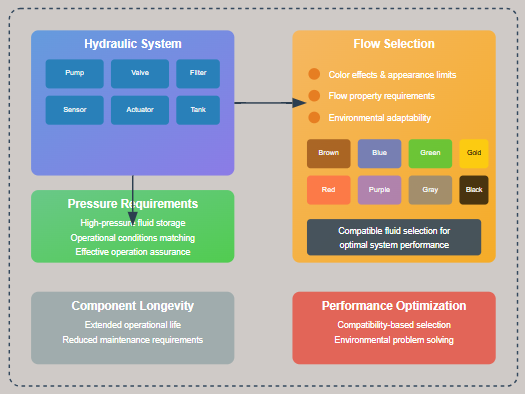

Working pressure represents the actual output pressure of hydraulics pumps during operation, corresponding to the resistance that must be overcome in the hydraulic circuit. For hydraulic motors, working pressure refers to the input pressure required for operation. This parameter directly influences system design, component selection, and overall performance.

Rated pressure defines the maximum continuous operating pressure that hydraulics pumps or motors can sustain under standard conditions without experiencing accelerated wear or failure. Operating beyond rated pressure constitutes overload conditions that may compromise reliability and service life.

Suction pressure, specific to hydraulics pumps, indicates the pressure condition at the pump inlet. Proper suction conditions are critical for preventing cavitation and ensuring optimal pump performance. Insufficient suction pressure can lead to incomplete chamber filling, reduced volumetric efficiency, and potential damage from cavitation erosion.

| Pressure Level | Pressure Range (MPa) | Common Applications |

|---|---|---|

| Low Pressure | ≤2.5 | Agricultural equipment, small tools, lubrication systems |

| Medium Pressure | >2.5-8 | Industrial machinery, material handling, automotive systems |

| Medium-High Pressure | >8-16 | Hydraulic presses, construction equipment, injection molding |

| High Pressure | >16-32 | Heavy machinery, mining equipment, metal forming |

| Ultra-High Pressure | >32 | Water jet cutting, specialized industrial forming processes |

Displacement (V) represents the theoretical volume of fluid that hydraulics pumps can deliver (or motors require) per complete shaft revolution, assuming no internal leakage. This fundamental parameter determines the size and capacity of hydraulic machines and directly influences system design calculations.

Indicates the volumetric output (or input for motors) per unit time without considering leakage losses. For hydraulics pumps operating at rotational speed n, the theoretical flow rate equals:

Accounts for internal leakage inherent in all hydraulics pumps and motors. For pumps, actual flow rate is less than theoretical flow rate due to internal leakage from high-pressure regions to low-pressure regions.

Specifies the flow rate of hydraulics pumps or motors operating at rated speed and pressure. This standardized parameter facilitates component selection and system design by providing a consistent performance reference point.

The power conversion process in hydraulics pumps involves transforming mechanical input (torque and rotational speed) into hydraulic output (pressure and flow rate). Hydraulic motors reverse this process, converting hydraulic power into mechanical output. Understanding these power relationships is essential for system design and efficiency optimization.

The theoretical power relationship for hydraulics pumps and motors, assuming no energy losses, is expressed as:

Practical hydraulics pumps and motors experience energy losses during conversion, resulting in output power less than input power. These losses comprise:

Result from internal leakage between high and low-pressure regions, increasing with pressure

Arise from friction between moving components, bearings, and seals

Combines both effects: η = ηVηm

ηV = q/qt = 1 - q1/qt

ηm = Tt/T (pumps) or ηm = T/Tt (motors)

η = ηV × ηm

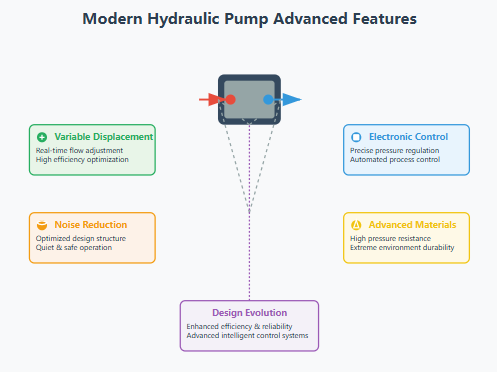

Contemporary hydraulics pumps have evolved significantly from their early predecessors, incorporating advanced materials, precision manufacturing, and intelligent control systems. These advancements have resulted in dramatic improvements in efficiency, reliability, and performance across all pressure ranges.

Allows real-time adjustment of flow output without speed changes, improving system efficiency and reducing energy consumption. Advanced control algorithms optimize displacement based on load requirements.

Enables precise pressure and flow regulation, supporting advanced automation and process control applications. Smart pumps can communicate with system controllers for optimized performance.

Address environmental and workplace concerns through optimized porting, reduced pressure pulsations, and improved mechanical tolerances, contributing to quieter operation without sacrificing performance.

Extend operating envelopes into extreme pressure and temperature ranges. High-strength alloys, advanced surface treatments, and engineered polymers enable operation in demanding environments.

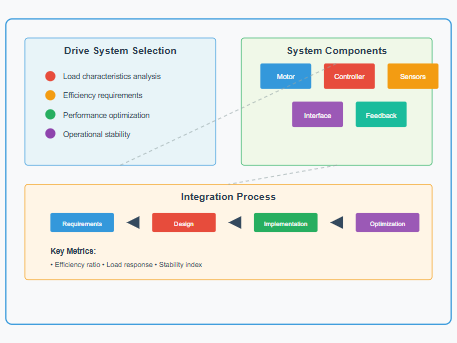

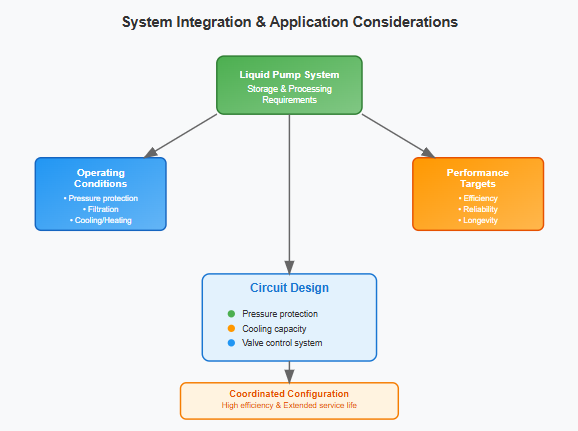

Successful application of hydraulics pumps requires careful consideration of system requirements, operating conditions, and performance objectives. Matching pump characteristics to load requirements ensures efficient operation and extended component life.

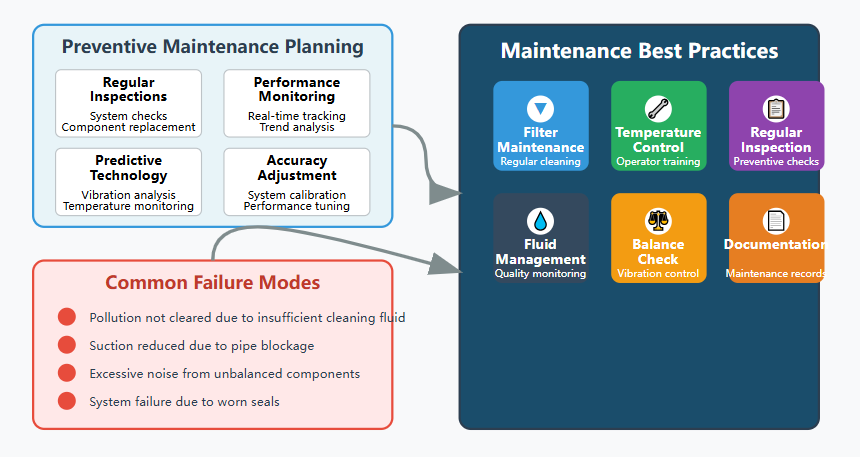

Maximize the service life and reliability of hydraulics pumps through systematic inspection, testing, and component replacement. These programs are essential for avoiding unplanned downtime and reducing lifecycle costs.

Detects contamination and degradation before significant damage occurs. Provides early warning of potential issues with wear particles or fluid breakdown.

Identifies developing problems enabling corrective action before failure. Tracks efficiency trends and performance degradation over time.

Vibration analysis, thermography, and oil analysis enable condition-based maintenance optimizing reliability and maintenance costs.

Initial system flushing removes construction contamination. Gradual break-in allows optimal running clearances to develop.

Regular filter replacement prevents contamination

Maintain optimal operating temperatures

Prevent minor issues becoming major failures

Follow manufacturer recommendations

Ensure proper shaft alignment

Maintain service records for trend analysis

The evolution of hydraulics pumps continues driven by demands for improved efficiency, reduced environmental impact, and enhanced functionality. These advancements position hydraulics pumps as key components in sustainable fluid power systems meeting future energy and environmental challenges.

Promise step-change improvements in controllability and efficiency through discrete flow control and intelligent algorithms.

Integration of sensors and communication capabilities supports Industry 4.0 initiatives through real-time performance monitoring.

Water-based hydraulics address environmental concerns in specific applications with innovative material solutions.

Systems incorporating hydraulics pumps as motors during deceleration improve overall system efficiency.

Hydraulics pumps remain fundamental components in fluid power systems across diverse industrial, mobile, and aerospace applications. Understanding their operating principles, performance characteristics, and application requirements enables optimal selection and application supporting efficient, reliable system operation.

Continued technological advancement ensures hydraulics pumps will maintain their critical role in power transmission and control applications while meeting evolving performance, efficiency, and environmental requirements. The comprehensive knowledge of pressure relationships, flow characteristics, efficiency factors, and system integration considerations presented here provides the foundation for successful application of these essential fluid power components in current and future hydraulic systems.