Menu

An comprehensive guide to hydraulic pump technology, applications, and selection criteria for industrial and mobile equipment.

Hydraulic pumps serve as the heart of hydraulic systems, converting mechanical energy into hydraulic energy through the pressurization of hydraulic fluid. These essential components have become indispensable across numerous sectors of the global economy, from manufacturing facilities to mobile equipment applications.

The selection and implementation of appropriate hydraulic pumps significantly impact system efficiency, operational costs, and overall equipment performance.

In contemporary industrial applications, hydraulic pumps operate across diverse environments and conditions, necessitating careful consideration of multiple factors during the selection process. The fundamental principle underlying all hydraulic pumps involves creating flow through mechanical action, though the specific mechanisms vary considerably among different pump types.

Cutaway view of a hydraulic pump showing internal components and fluid flow paths

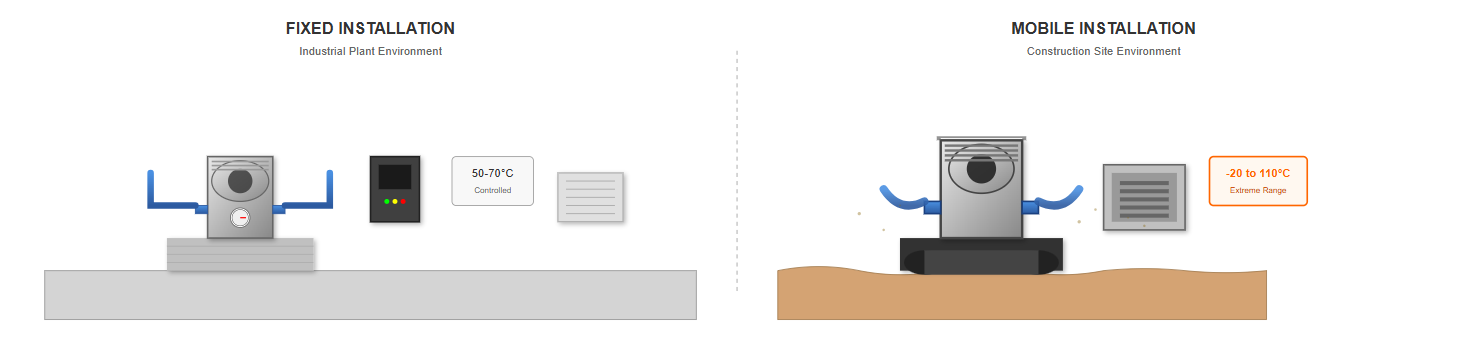

The application spectrum for hydraulic pumps can be systematically categorized into two primary classifications, each presenting distinct operational requirements and environmental considerations.

These systems are predominantly found in stationary industrial installations. They typically include various machine tools, hydraulic presses, injection molding machines, and steel rolling mills.

Mobile applications include construction equipment such as cranes and excavators, transportation vehicles, aircraft hydraulic systems, and agricultural machinery.

Fixed equipment installations utilizing hydraulic pumps typically operate within climate-controlled environments, maintaining relatively stable temperature ranges between 50-70°C. These controlled conditions contribute to consistent fluid viscosity, predictable thermal expansion characteristics, and reduced contamination risks.

The indoor operating environment also facilitates regular maintenance schedules and allows for more sophisticated monitoring systems.

Conversely, mobile equipment hydraulic pumps must function reliably across extreme temperature variations, often ranging from -20°C to 110°C. This broad temperature spectrum necessitates careful selection of hydraulic fluids, enhanced sealing systems, and robust component designs capable of maintaining performance despite thermal cycling.

Additionally, mobile hydraulic pumps encounter significantly higher contamination levels from airborne particles, requiring superior filtration systems and more frequent maintenance intervals.

Comparison of operating environments: industrial plant with fixed hydraulic systems (left) and construction site with mobile hydraulic equipment (right)

Fixed installations predominantly utilize electric motors as prime movers, typically operating at stable speeds around 1450 rpm. This consistency enables optimization of pump design for specific operating points, maximizing efficiency and minimizing wear.

Electric motor drives also facilitate precise control strategies, including variable frequency drives for enhanced system flexibility.

Mobile equipment hydraulic pumps must accommodate internal combustion engines with highly variable operating speeds, typically ranging from 500 to 4000 rpm. This variability demands pumps capable of maintaining acceptable performance across the entire speed range.

The intermittent loading patterns common in mobile applications further complicate pump selection and system design.

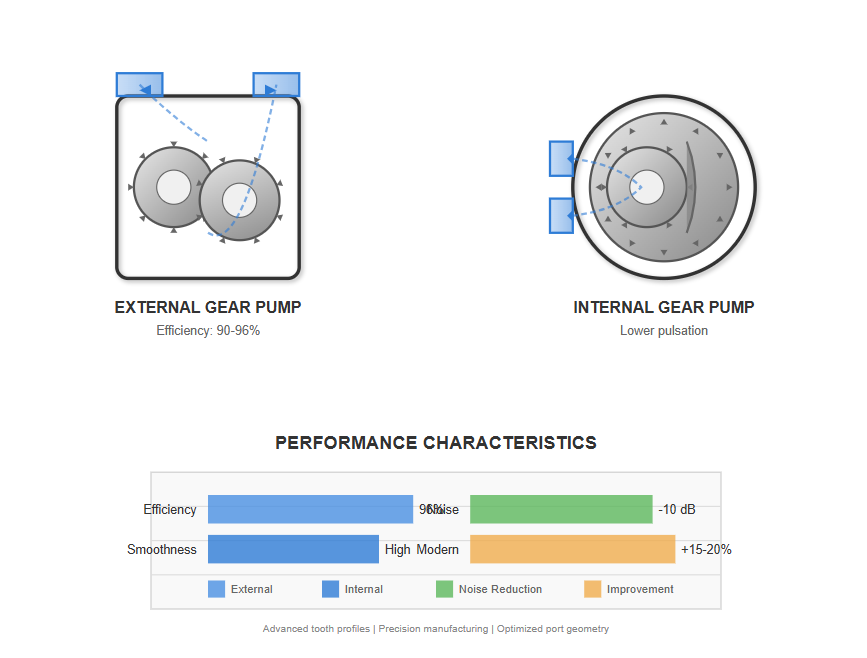

External and internal gear pump designs showing gear configurations and fluid flow paths

External gear hydraulic pumps represent one of the most widely utilized pump designs due to their simplicity, reliability, and cost-effectiveness. These pumps typically achieve volumetric efficiencies up to 96% in optimal conditions, with total efficiencies reaching 90%.

Internal gear pumps, including both involute and cycloidal (gerotor) designs, offer distinct advantages in specific applications. Involute internal gear hydraulic pumps provide smoother flow characteristics with reduced pulsation compared to external gear designs.

"Modern gear pump designs incorporating advanced tooth profiles and precision manufacturing techniques have demonstrated efficiency improvements of 15-20% compared to conventional designs, while simultaneously reducing noise emissions by up to 10 dB through optimized porting geometry and reduced cavitation tendencies."

Johnson, R.K., et al., "Advanced Gear Pump Technologies for Industrial Applications," Journal of Fluid Power Systems, Vol. 45, No. 3, 2023

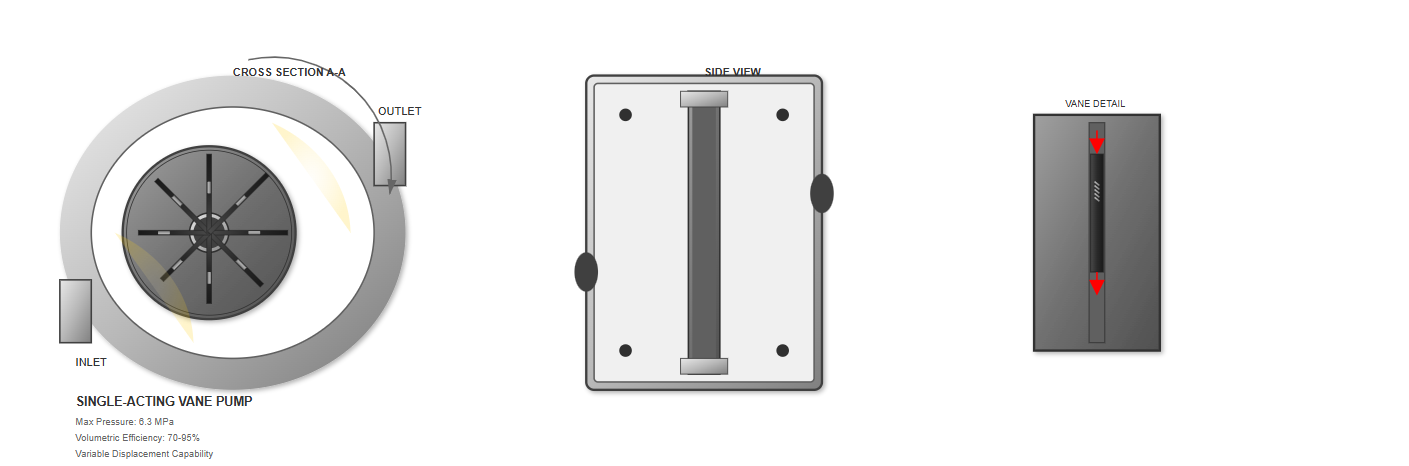

Single-acting vane hydraulic pumps utilize spring-loaded or hydraulically actuated vanes that maintain contact with the cam ring throughout rotation. These pumps typically operate at pressures up to 6.3 MPa, with volumetric efficiencies ranging from 70-95%.

The inherent unbalanced radial forces in single-acting designs limit their application to lower pressure ranges but enable variable displacement capability through cam ring adjustment.

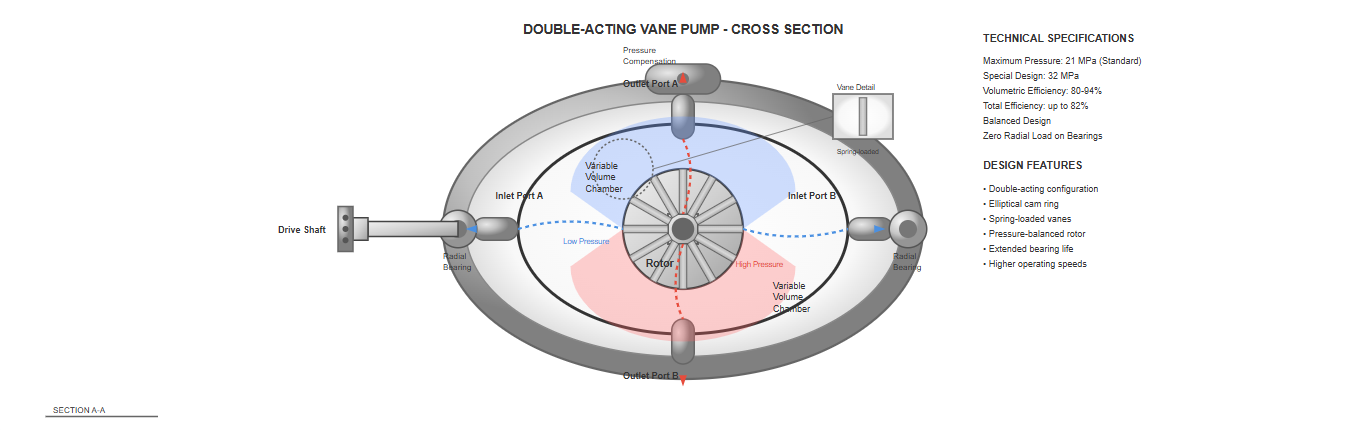

Double-acting vane pumps employ a balanced design that eliminates radial bearing loads, enabling higher pressure operation up to 21 MPa in standard configurations and 32 MPa in specialized designs.

These hydraulic pumps demonstrate excellent volumetric efficiency characteristics, typically 80-94%, with total efficiencies reaching 82%. The balanced design extends bearing life and enables higher speed operation.

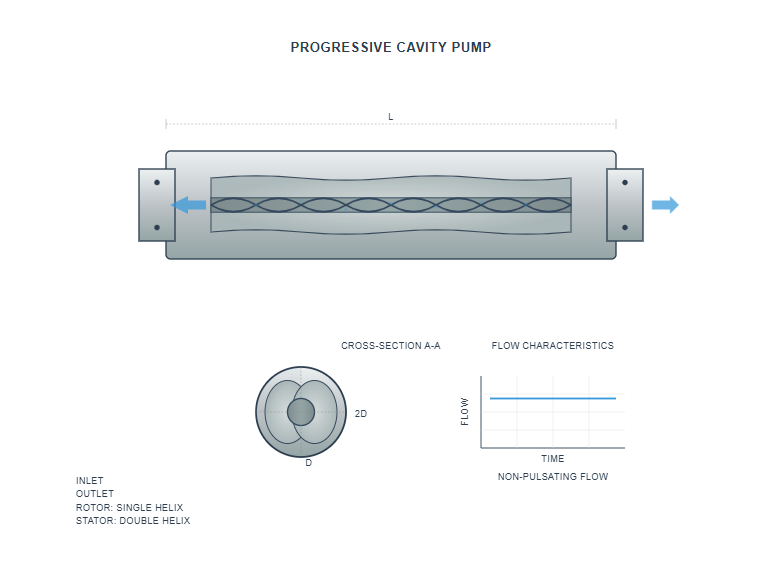

Screw pump design showing helical rotors that produce smooth, pulsation-free flow

Screw hydraulic pumps provide exceptionally smooth, pulsation-free flow characteristics, making them ideal for precision applications requiring minimal pressure ripple. Operating pressure capabilities reach 10 MPa for standard designs, with volumetric efficiencies ranging from 70-95%.

The continuous, non-pulsating flow produced by screw pumps proves particularly valuable in applications such as precision machine tools, food processing equipment, and chemical processing systems.

The low noise characteristics of screw pumps, combined with their ability to handle fluids with varying viscosities, expand their application range beyond traditional hydraulic systems. Displacement ranges from 0.5 to 480 mL/rev accommodate diverse flow requirements.

Piston pumps represent the high-performance category of hydraulic pumps, offering superior pressure capabilities and efficiency for demanding applications across both fixed and mobile equipment.

| Piston Pump Type | Max Pressure (MPa) | Volumetric Efficiency (%) | Total Efficiency (%) | Displacement Range (mL/rev) | Key Applications |

|---|---|---|---|---|---|

| Axial (Swashplate) | 40 (70 specialized) | 88-93 | 81-88 | 0.2-5600 | Industrial machinery, mobile equipment |

| Bent-axis Axial | 40 | 87-92 | 80-87 | 0.5-1000 | Mobile equipment, aerospace |

| Radial | 70+ | 90-95 | 83-86 | 1-2000 | High-pressure test stands, specialized machinery |

Swashplate designs achieve exceptional pressure capabilities while offering variable displacement for precise flow control in both industrial and mobile applications.

Offer superior performance at high speeds with improved starting torque, making them ideal for mobile equipment with variable speed requirements.

Provide exceptional pressure capabilities with inherent balance that minimizes bearing loads, suitable for high-pressure industrial applications.

Acoustic considerations significantly influence hydraulic pump selection, particularly in fixed equipment installations. Indoor industrial environments typically mandate noise levels below 80 dB to ensure operator comfort and regulatory compliance.

Requires noise levels below 80 dB. Internal gear and screw hydraulic pumps excel in low-noise applications, while external gear pumps may require additional acoustic treatment.

Generally tolerates higher noise levels, up to 90 dB. Advanced piston pump designs incorporating pre-compression volumes and optimized valve plate geometry significantly reduce fluid-borne noise.

The sensitivity of different hydraulic pumps to fluid contamination varies considerably among pump types and influences both selection decisions and maintenance strategies.

Available primarily in vane and piston configurations, these pumps enable precise flow control through mechanical, hydraulic, or electronic displacement adjustment.

These capabilities prove essential in applications requiring load-sensing control, pressure compensation, or power limitation.

Include most gear and screw designs, requiring external flow control methods such as bypass valves or variable speed drives.

While adding complexity, these approaches offer flexibility in system design and can achieve comparable efficiency when properly implemented.

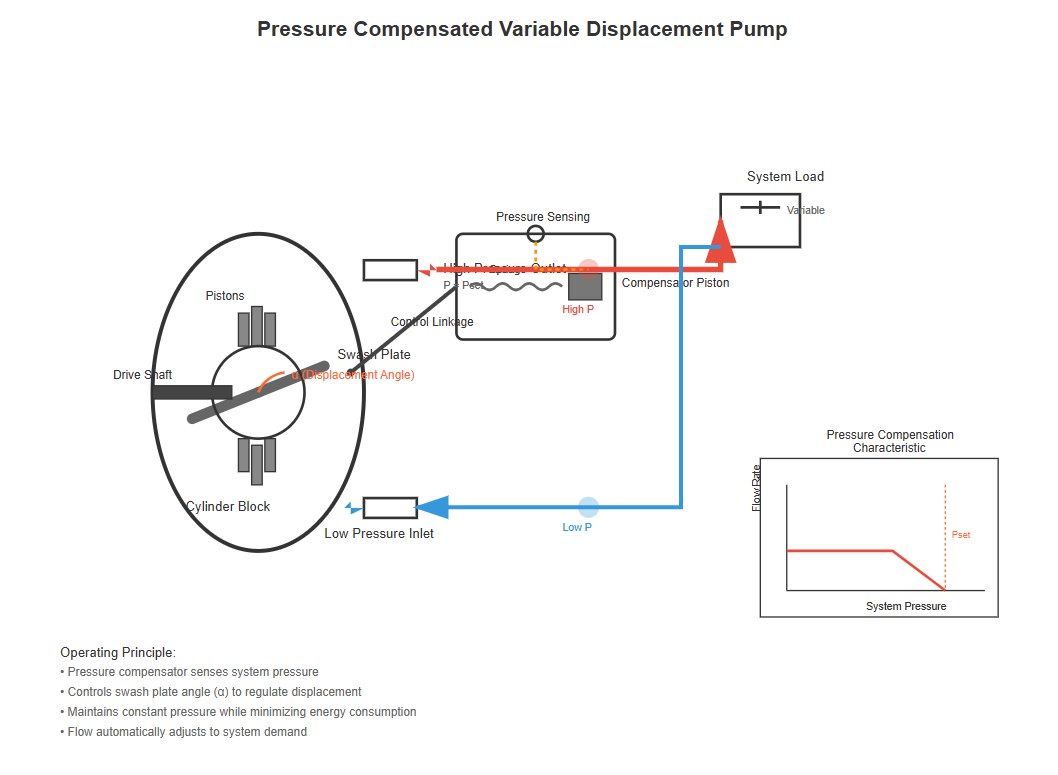

Pressure compensated variable displacement hydraulic pumps automatically adjust their displacement to maintain system pressure at a predetermined setpoint. This sophisticated control mechanism involves a pressure-sensing element, typically a spring-loaded spool or piston, that modulates pump displacement in response to system pressure variations.

When system pressure approaches the setpoint, the compensator reduces pump displacement, maintaining pressure while minimizing energy consumption. The control dynamics require careful consideration of system requirements and stability criteria.

Pressure compensated pump operation showing displacement adjustment in response to system pressure changes

Benefit from energy efficiency during clamping and holding operations, where traditional fixed displacement pumps would waste energy through relief valves.

Varying flow requirements during approach, pressing, and return strokes align perfectly with pressure compensated capabilities, achieving 30-50% energy savings.

Optimize engine loading and fuel consumption by matching pump output to actual demand, eliminating excess flow and associated losses.

5-35 MPa

50-350 bar

1-2 bar

Precision control capability

50-200 ms

Depending on pump size

2-5%

Of setting pressure

Proportional and servo controls enable precise displacement modulation based on complex algorithms. Digital communication protocols facilitate integration with broader machine control systems, enabling coordinated multi-pump operations and advanced diagnostics.

Variable speed drives combined with fixed displacement pumps offer alternatives to traditional designs, potentially achieving superior part-load efficiency. Hybrid systems with energy storage enable energy recovery during deceleration or lowering operations.

Ceramic and composite materials enable operation at higher pressures and temperatures. Additive manufacturing facilitates complex internal geometries that optimize flow patterns. Precision techniques achieve tighter tolerances improving efficiency.

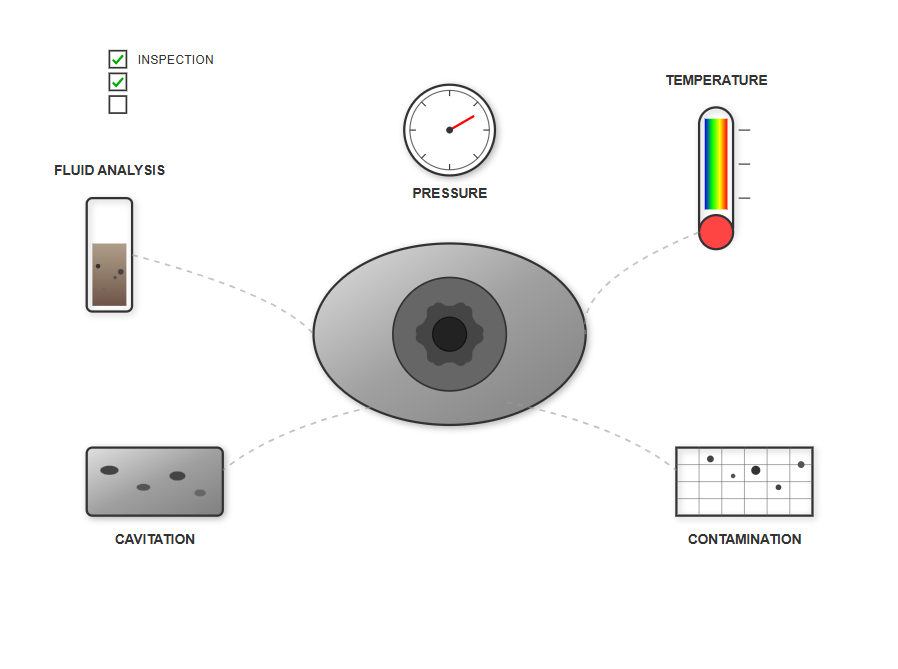

Regular fluid analysis identifies contamination trends and degradation patterns before they impact pump performance. Key parameters include:

Temperature monitoring provides valuable insights into pump condition and system operation. Excessive temperatures indicate potential problems including cavitation, excessive internal leakage, or system restrictions. Continuous monitoring with alarm capabilities prevents catastrophic failures due to overheating.

Hydraulic pump maintenance inspection revealing contamination-related wear patterns

Caused by insufficient inlet pressure, resulting in erosion damage and reduced performance. Proper system design including adequate reservoir sizing, appropriate inlet line dimensions, and controlled fluid temperature prevents cavitation-related failures.

Particulate contamination accelerates wear of precision surfaces, reducing efficiency and eventually causing failure. Implementing appropriate filtration strategies, maintaining proper fluid cleanliness levels, and preventing contamination ingression significantly extend pump life.