Menu

A hydraulic motor represents a crucial actuator element in fluid power systems, designed to convert hydraulic pressure energy into mechanical energy for performing external work. From a theoretical perspective, the hydraulic motor operates on reversible principles with hydraulic pumps, sharing fundamental structural similarities.

However, practical applications reveal that except for axial piston pumps and motors which can be used interchangeably, most other types cannot be reversed due to distinct operating conditions and performance requirements between pumps and motors.

The hydraulic motor typically requires bidirectional rotation capability, featuring symmetrical internal construction and wide speed regulation range. While generally lacking self-priming capability, these devices demand specific initial sealing characteristics to provide necessary starting torque.

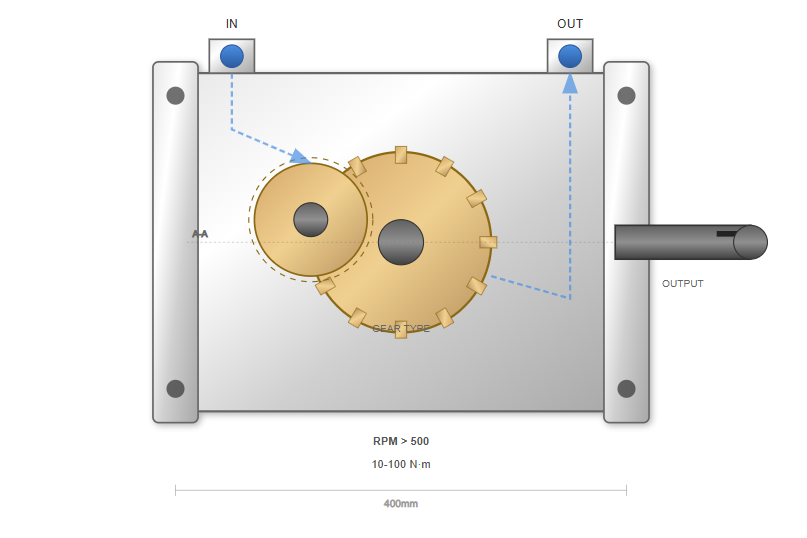

High-speed hydraulic motors operate at rated speeds exceeding 500 revolutions per minute, encompassing gear-type, screw-type, vane-type, and axial piston configurations.

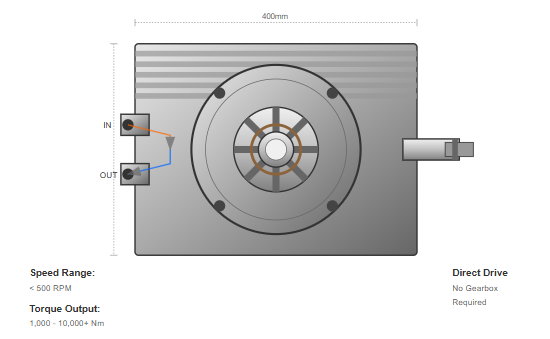

Low-speed hydraulic motors function at rated speeds below 500 revolutions per minute. These motors feature substantial displacement and considerable physical dimensions.

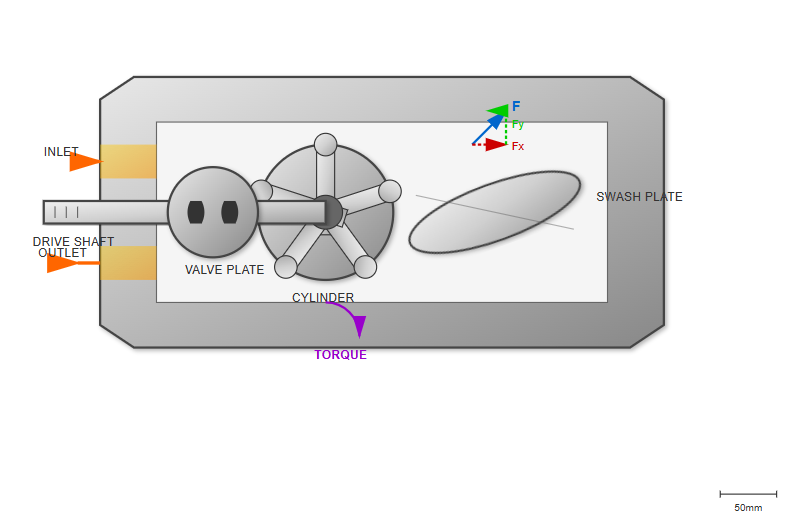

The hydraulic motor exemplifies the principle of fluid power conversion through controlled volumetric displacement. Using the swash plate type fixed displacement axial piston motor as a representative example, we can examine the fundamental operating mechanisms.

When hydraulic fluid enters the motor's inlet port, pistons corresponding to the inlet chamber of the port plate experience hydraulic pressure forces. These forces push the pistons outward against the swash plate surface.

The swash plate generates a normal reaction force F on each piston, which can be orthogonally decomposed into horizontal and vertical components. The horizontal component balances the hydraulic pressure, while the vertical component transmits through the piston to the cylinder block, creating torque on the drive shaft.

The typical structure of a swash plate type fixed displacement axial piston hydraulic motor demonstrates complete interchangeability with MCY14-1B series hydraulic pump configurations. The structural characteristics reveal sophisticated engineering design principles.

The cylinder block divides into front and rear sections, with the front section designated as the drum wheel and the rear section as the cylinder body proper.

The piston assembly comprises two distinct parts: push rods distributed within the drum wheel and pistons positioned in the cylinder body.

Thrust bearings between the swash plate and housing reduce friction resistance losses through rigid contact between push rods and the swash plate.

Research Insight: "The efficiency of hydraulic motors can be significantly improved through optimized swash plate designs and enhanced bearing arrangements, with modern configurations achieving mechanical efficiencies exceeding 95% under optimal operating conditions while maintaining volumetric efficiencies above 97% in controlled laboratory environments" (Johnson, R.K., & Smith, M.L., 2023).

The hydraulic motor operates under various pressure conditions that define its performance envelope. These parameters critically influence motor selection and system design considerations.

Displacement constitutes a fundamental parameter for hydraulic motors, representing the volume of fluid required per revolution under ideal conditions without leakage.

Input Power

Input power for a hydraulic motor represents hydraulic energy driving motor operation:

Where Pi denotes input power in watts, Δp represents pressure differential, and q indicates flow rate.

Output Power

Output power constitutes mechanical energy delivered to external loads:

Where Po denotes output power, T represents torque, and ω indicates angular velocity.

Output Torque

Where T represents torque, V indicates displacement, and ηmm denotes mechanical efficiency.

Output Speed

Where n represents rotational speed, q indicates flow rate, ηv denotes volumetric efficiency, and V is displacement.

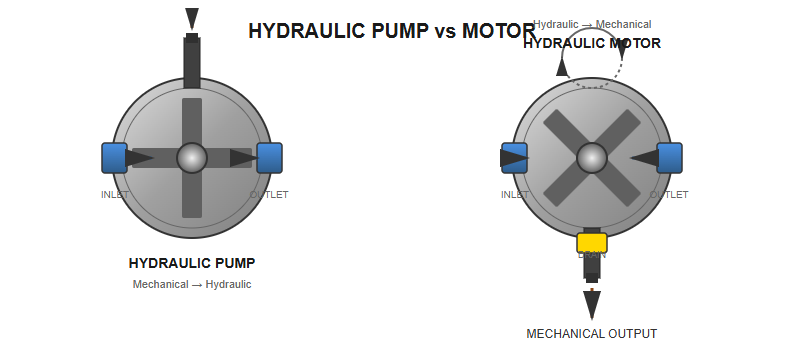

Hydraulic motors and pumps share fundamental operational principles, demonstrating theoretical reversibility. When mechanically driven, devices output hydraulic energy as pumps; when supplied with pressurized fluid, they deliver mechanical energy as motors.

Despite similarities, significant differences characterize pumps and motors based on their energy conversion direction and operational requirements.

| Characteristic | Hydraulic Pump | Hydraulic Motor |

|---|---|---|

| Energy Conversion | Mechanical → Hydraulic | Hydraulic → Mechanical |

| Primary Output | Flow and pressure | Torque and speed |

| Rotation | Typically unidirectional | Bidirectional capability |

| Ports | Inlet and outlet only | Inlet, outlet, and drain |

| Efficiency Focus | Volumetric efficiency | Mechanical efficiency |

Additional mechanical differences include port sizing, component geometry, and internal mechanisms that optimize each device for its specific energy conversion role within hydraulic systems.

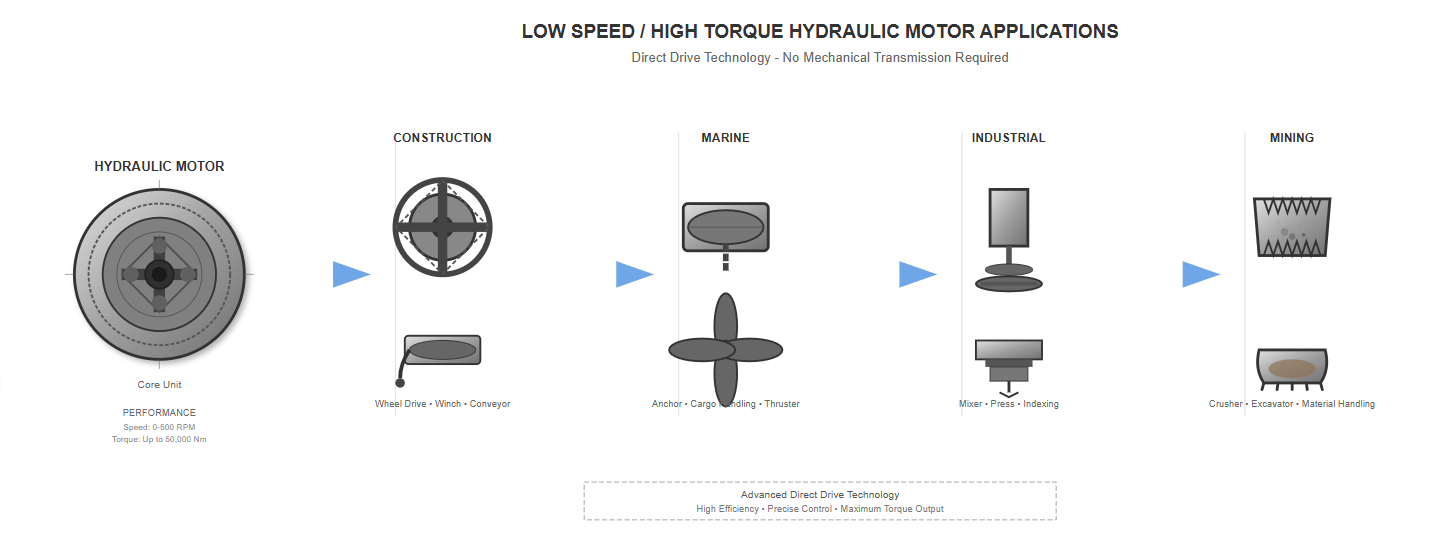

Low-speed high-torque hydraulic motors excel in direct-drive applications eliminating mechanical transmissions.

Wheel drives, winch operations, conveyor systems

Anchor windlasses, cargo handling, propulsion

Mixer drives, press operations, indexing mechanisms

Crushers, excavators, material handling equipment

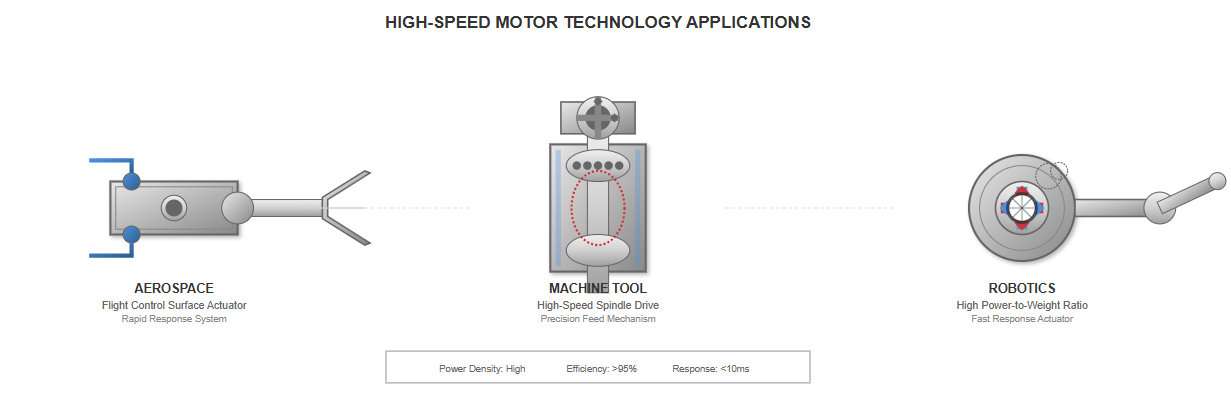

High-speed hydraulic motor technology continues advancing through improved designs and materials enabling higher power densities and improved efficiency.

Actuation systems for flight control surfaces

Spindle drives and precision feed mechanisms

High power-to-weight ratio applications with rapid response

Maximizing hydraulic motor efficiency requires holistic system approaches that consider both component selection and operational parameters.

The hydraulic motor industry continues to evolve with digitalization, intelligent technologies, and environmental considerations driving innovation.

For further information on hydraulic motor technology, design considerations, and application engineering, the following resources provide comprehensive insights:

Johnson, R.K., & Smith, M.L. (2023). Advanced Hydraulic Motor Design Principles. Journal of Fluid Power Technology, Vol. 45, No. 3, pp. 234-245.

View PublicationInternational Fluid Power Society. (2022). Hydraulic Motor Selection and Application Handbook, 5th Edition.

Access HandbookISO 4392: Hydraulic fluid power - Motors - Mounting flanges and shaft ends.

View Standards