Menu

A comprehensive analysis of the working principles, operational characteristics, and application scenarios of hydraulic valves in modern industrial systems.

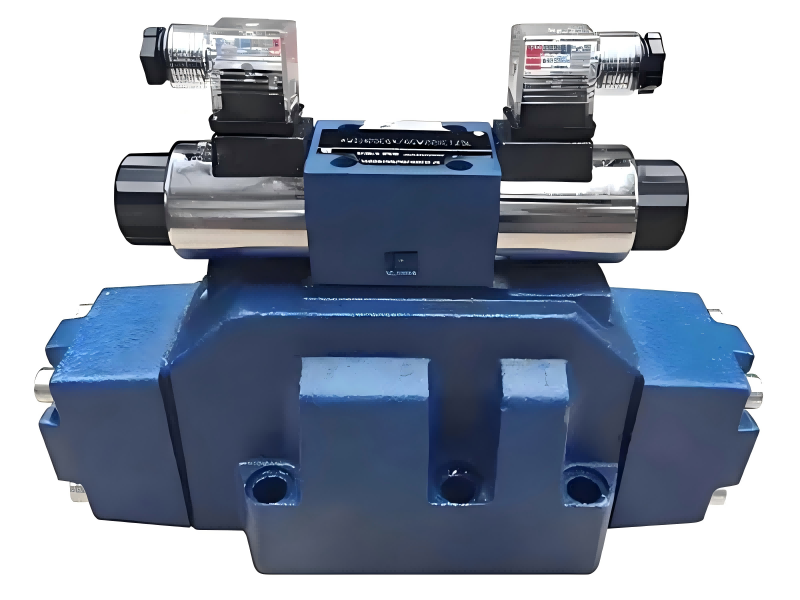

Hydraulic valves represent critical control and regulation components within hydraulic systems, serving as the fundamental elements that control and regulate the pressure, flow rate, and direction of hydraulic fluid flow. In modern industrial equipment and engineering applications, hydraulic valves have evolved into sophisticated devices with complex structures and continuously emerging innovative designs. The comprehensive analysis and research of commonly used hydraulic valves, including their working principles, operational characteristics, and application scenarios, proves essential for understanding hydraulic equipment working processes, system performance evaluation, and optimal system design implementation.

The significance of hydraulic valves in industrial applications cannot be overstated, as they form the backbone of fluid power control systems across numerous sectors including manufacturing, construction, aerospace, and automotive industries. This article provides an in-depth examination of typical structures, working principles, and distinctive characteristics of commonly utilized hydraulic components in contemporary engineering applications.

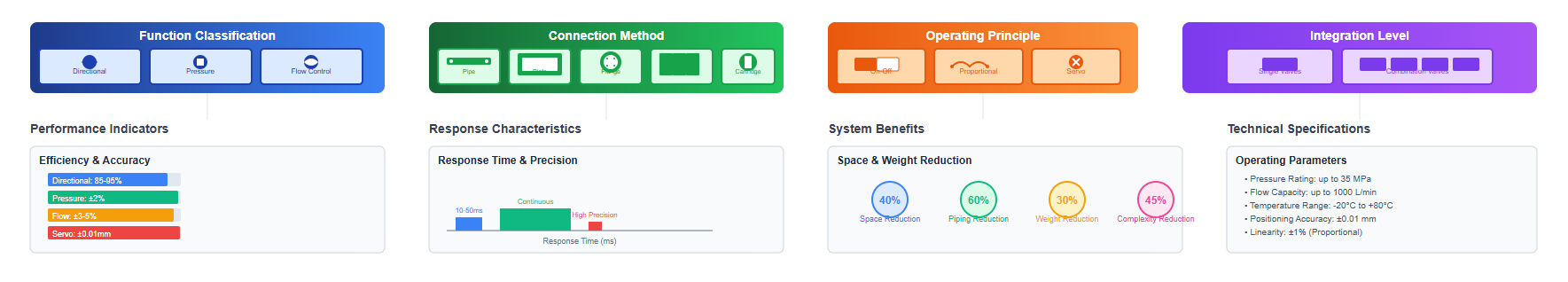

To develop a comprehensive understanding of hydraulic valves, it is crucial to examine their classification methods, characteristics, and commonly used parameters. The variety of hydraulic valves has expanded to encompass several hundred types with thousands of specifications, reflecting the diverse requirements of modern industrial applications. From different analytical perspectives, hydraulic valves can be classified through multiple categorization systems:

Hydraulic valves function as control and regulation elements, inherently consuming a certain amount of energy during operation. The sealing method between the valve spool and valve body typically employs clearance sealing (excluding ball valves), which inevitably results in internal leakage. The fundamental performance requirements for hydraulic valves encompass several critical aspects to ensure optimal spool movement flexibility while minimizing leakage:

| Performance Characteristic | Specification |

|---|---|

| Manufacturing Precision | Tolerances maintained within ±0.001-0.005 mm |

| Spool Movement Flexibility | Actuation forces typically 5-20 N |

| Operational Reliability | MTBF (Mean Time Between Failures) exceeding 10,000 hours |

| Sealing Performance | Internal leakage rates below 5 cm³/min at rated pressure |

| Structural Compactness | Volume reduction of 25-35% in modern designs |

| Working Efficiency | Overall efficiency ratings of 90-98% |

| Component Universality | Standardization achieving 80% interchangeability |

The operational capability of hydraulic valves is determined by their performance parameters. While basic parameters vary according to valve type, different hydraulic valves possess distinct performance characteristics. Common parameters primarily relate to pressure and flow specifications:

Nominal pressure serves as the parameter indicating the load-bearing capacity of hydraulic valves. The nominal pressure represents the designated pressure of hydraulic valves under rated working conditions, measured in MPa (Megapascals). Standard nominal pressure ratings include:

Flow parameters indicate the flow performance characteristics of hydraulic valves. Primary flow-related parameters include:

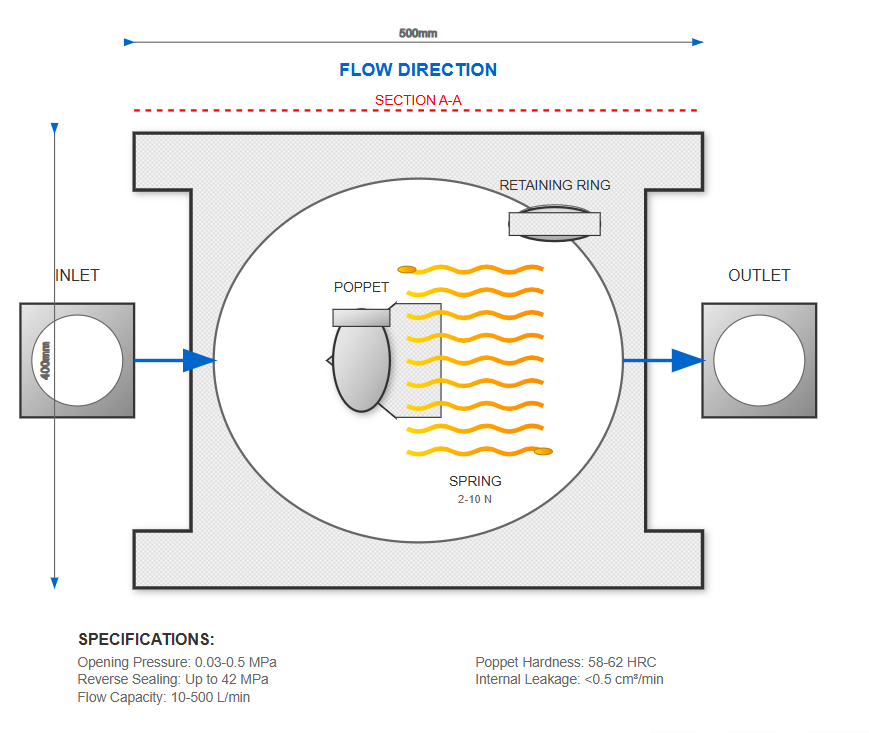

Check valves, also known as one-way valves or non-return valves, represent the simplest form of directional control valves in hydraulic systems. These valves permit fluid flow in one direction while preventing reverse flow, achieving directional control through mechanical means without external actuation.

The structural composition of ordinary straight-through check valves includes:

Performance specifications for standard check valves include:

Ordinary check valve cross-section showing internal components

The right-angle configuration offers advantages in specific installation scenarios, featuring:

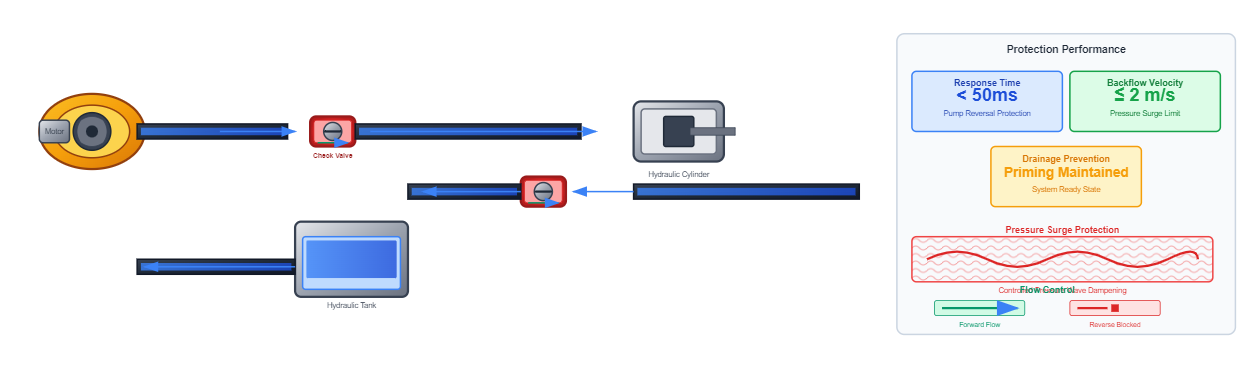

Installing check valves at pump outlets prevents reverse flow when pumps stop, protecting against:

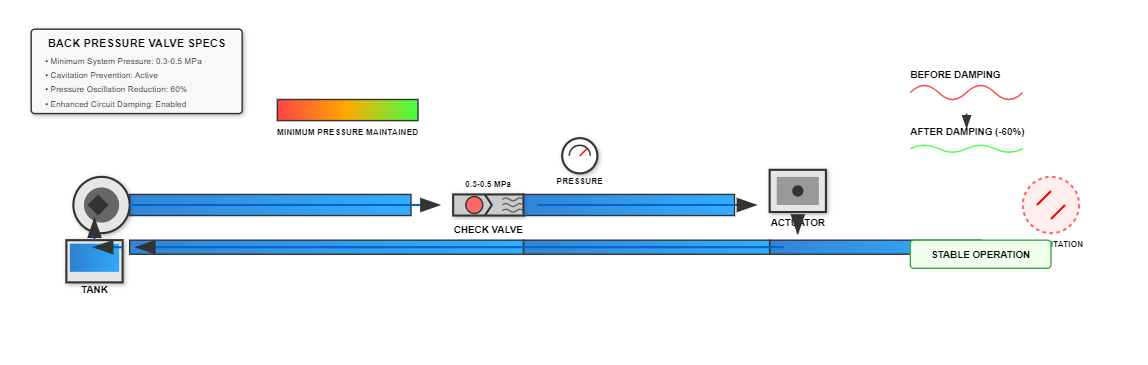

When utilized as back pressure valves, check valves maintain:

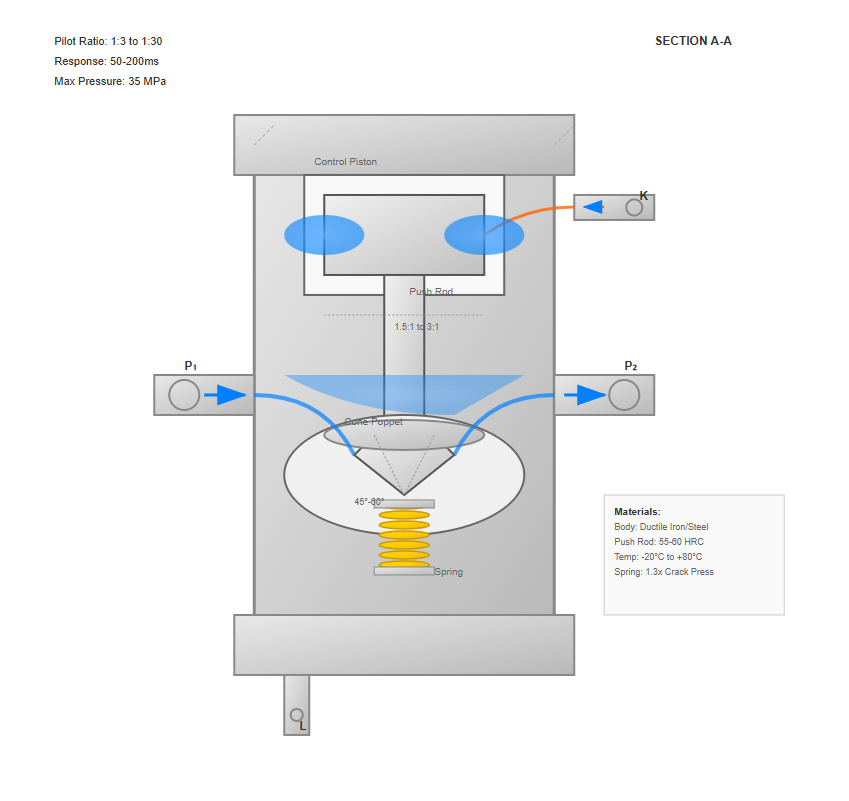

Pilot-operated check valves, also termed hydraulically unlocked check valves, enable bidirectional flow control through hydraulic pilot signals. The operational principle involves:

When pilot port K receives pressure signal (typically 3-5% of load pressure), the control piston drives the poppet lifter, mechanically opening the check valve to permit reverse flow from P₂ to P₁. Without pilot pressure, the valve functions as a conventional check valve, allowing flow from P₁ to P₂ while blocking reverse flow. The leakage port L ensures proper drainage of the spring chamber.

Key components include:

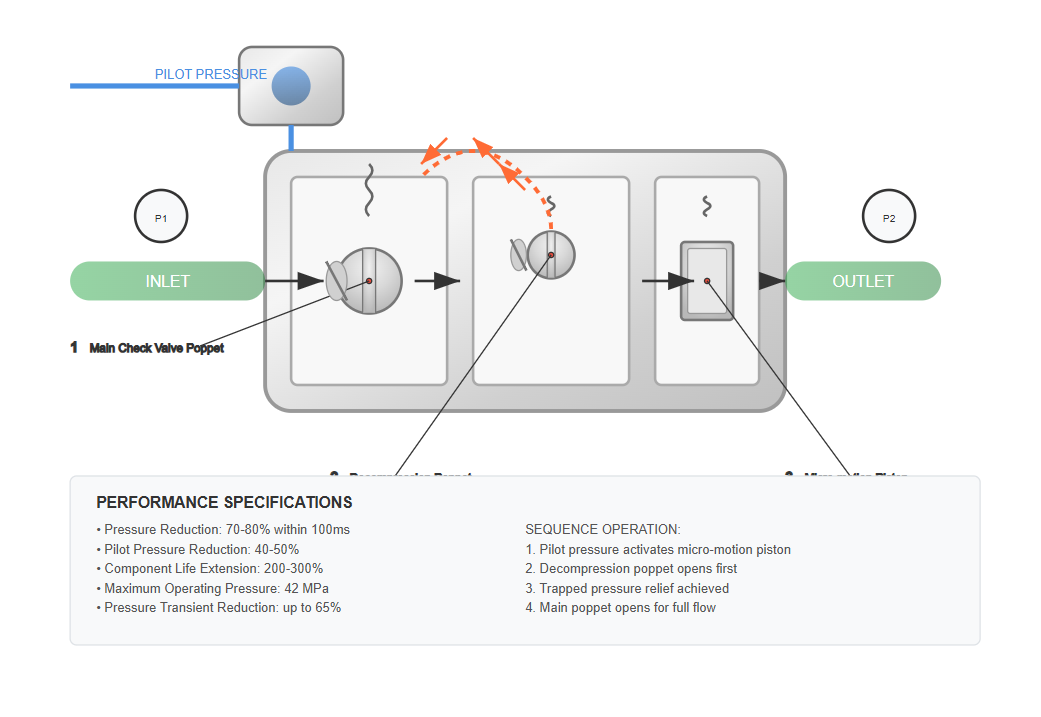

Advanced designs incorporate decompression valve cores to address high-pressure reverse opening challenges:

The decompression sequence operates as follows:

"The implementation of decompression mechanisms in pilot-operated check valves has demonstrated significant improvements in system stability and component longevity, with measured reductions in pressure transients of up to 65% compared to conventional designs."

— Zhang, L., & Smith, J.R., 2023, International Journal of Fluid Power

In pressing applications where workpiece compression requires sustained force:

For vertical cylinder applications supporting suspended loads:

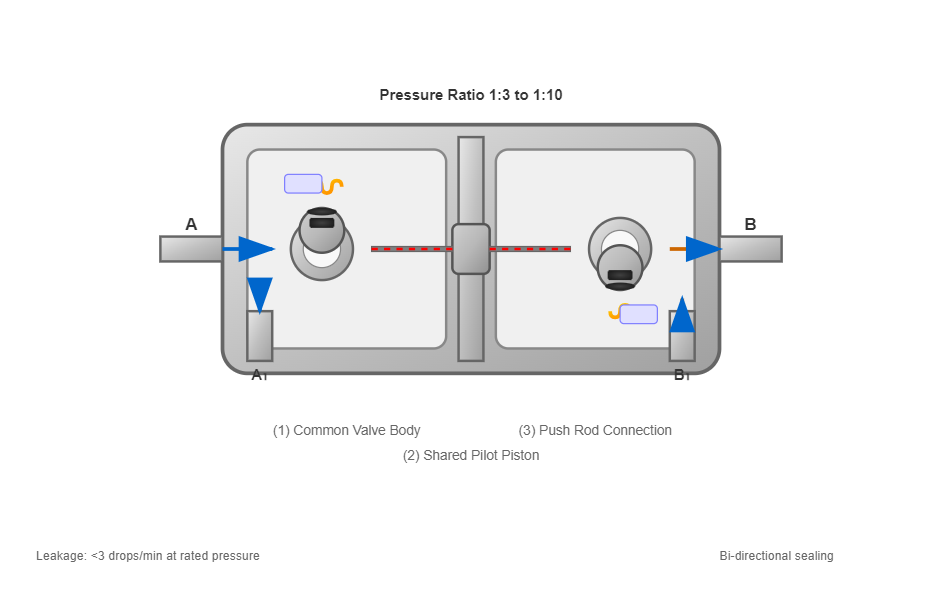

Dual pilot-operated check valves, commonly known as bi-directional hydraulic locks or dual counterbalance valves, integrate two pilot-operated check valves within a common housing. This configuration shares:

When port A receives pressurized flow:

Symmetrical operation from port B:

Without pressure at A or B:

| Parameter | Specification |

|---|---|

| Maximum operating pressure | 35-42 MPa |

| Flow capacity | 20-500 L/min |

| Pilot ratio options | 1:3, 1:4.25, 1:7, 1:10 |

| Response time | 100-300 milliseconds |

| Temperature range | -30°C to +100°C |

Modern hydraulic valves increasingly incorporate proportional control technology, offering:

Proportional hydraulic valves utilize electromagnetic actuators with force output proportional to input current (0-1600 mA typical).

High-performance servo valves deliver exceptional control capabilities:

These specifications enable applications in precision control systems requiring exceptional accuracy.

Emerging digital hydraulic valves represent the latest advancement:

Digital valve matrices demonstrate exceptional flow control range of 1:1000 without throttling losses.

Flight simulators requiring response times under 5 milliseconds and precise motion control.

Injection molding machines achieving ±0.01 mm positioning accuracy with servo valve control.

Material testing systems controlling force within ±0.1% accuracy using proportional valves.

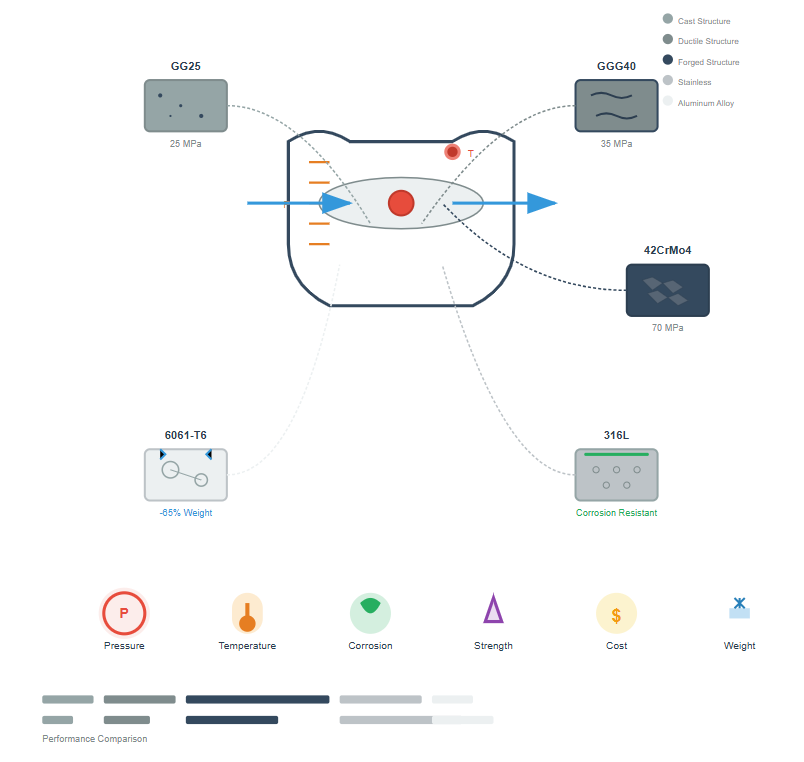

Selection of appropriate materials ensures optimal performance:

Cost-effective for pressures up to 25 MPa

Enhanced strength for 35 MPa applications

High-pressure service to 70 MPa

Corrosion resistance in aggressive fluids

Weight reduction of 65% for mobile equipment

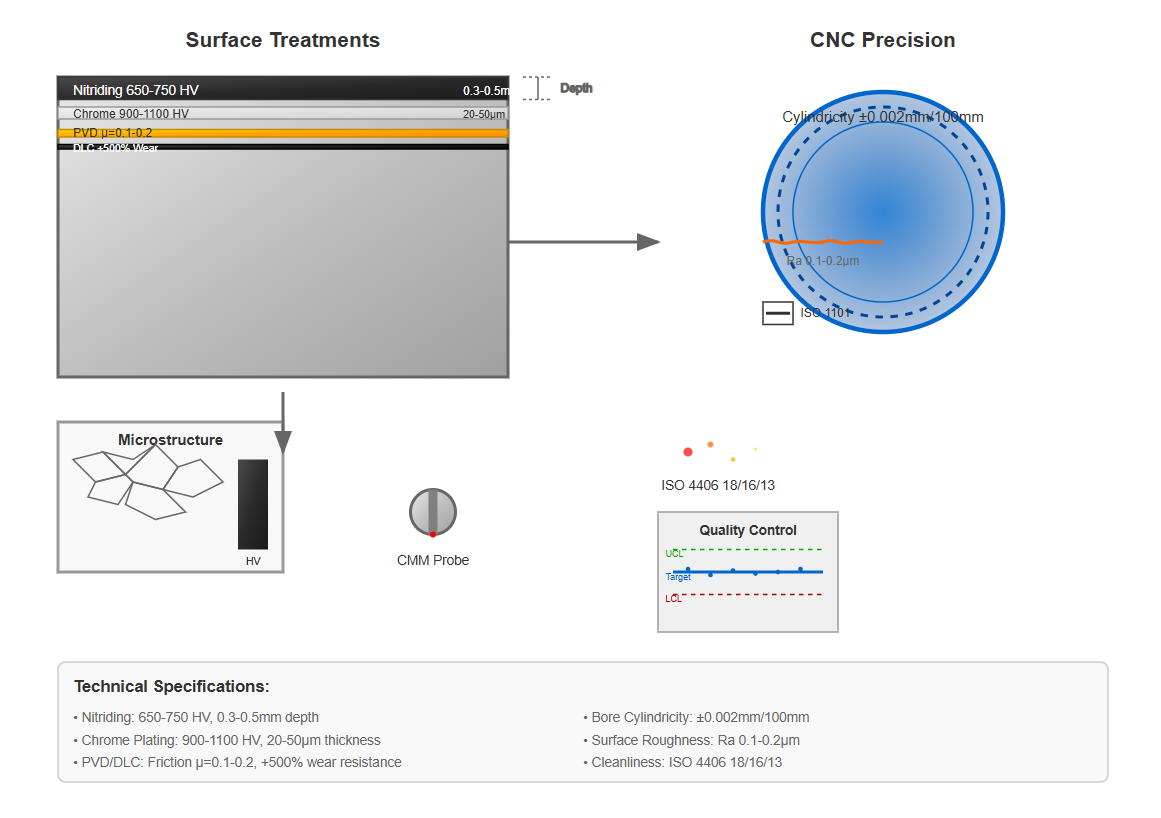

Advanced surface treatments extend hydraulic valves service life:

Surface hardness of 650-750 HV, depth 0.3-0.5 mm

Thickness 20-50 μm, hardness 900-1100 HV

Friction coefficient reduced to 0.1-0.2

Wear resistance improved by 500%

Modern CNC manufacturing achieves:

Bore cylindricity

Within 0.002 mm over 100 mm length

Surface roughness

Ra 0.1-0.2 μm for sealing surfaces

Geometric tolerances

Per ISO 1101 specifications

Cleanliness levels

Meeting ISO 4406 18/16/13 standards

Minimizing pressure losses across hydraulic valves requires:

Maintaining fluid cleanliness extends valve life:

Operating temperature significantly impacts valve performance:

Pressure drop characteristics vary with flow regime:

Laminar flow regime (Re < 2300):

ΔP proportional to flow rate

Turbulent flow regime (Re > 4000):

ΔP proportional to flow rate squared

Transition zone considerations:

For variable flow applications

Pressure Drop Formula:

ΔP = K × Qⁿ

Where K = pressure loss coefficient, Q = flow rate, and n = 1 for laminar flow, 2 for turbulent flow

70% of hydraulic valve failures

Attributed to contamination-related issues

300-500% component life extension

Achieved through proper filtration practices

60% reduction in maintenance costs

Resulting from effective contamination control

| Application Type | Operating Temperature Range | Special Considerations |

|---|---|---|

| Standard industrial | -20°C to +80°C | General purpose hydraulic fluids, standard seals |

| High-temperature | -10°C to +150°C | Fluorocarbon seals, synthetic fluids, thermal expansion compensation |

| Arctic specifications | -40°C to +50°C | Low-temperature hydraulic fluids, special seal materials |

| Mobile equipment | -30°C to +100°C | Wide-range fluids, robust sealing systems, thermal shock resistance |

| Test environments | -50°C to +180°C | Specialized materials, thermal insulation, temperature monitoring |

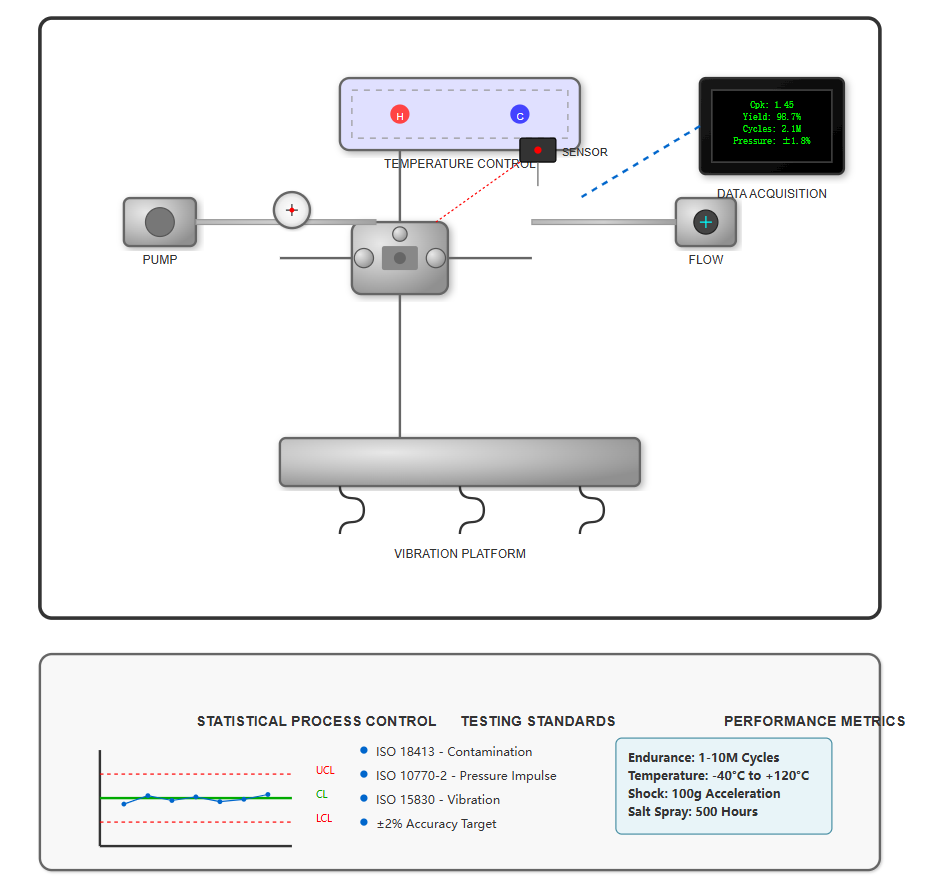

Comprehensive testing validates hydraulic valves specifications:

Manufacturing quality assurance encompasses:

Statistical process control

Maintaining Cpk > 1.33 for critical dimensions

First-pass yield rates

Exceeding 98% through process optimization

Zero-defect targets

For safety-critical applications in aerospace and defense

Traceability systems

Tracking components through production and service life

The ongoing evolution of hydraulic valve technology continues to enhance system efficiency, reliability, and performance across industrial sectors. As smart technologies, advanced materials, and energy-efficient designs become more prevalent, hydraulic systems will play an increasingly important role in sustainable manufacturing and automation.