Menu

Hydraulic systems are found across virtually every major industry, from construction equipment and aircraft to hospital beds and office chairs. These systems operate in environments ranging from underground mines to commercial jetliners, anywhere precise control and powerful force transmission are needed through pressurized fluid.

Manufacturing facilities rely heavily on hydraulic systems for core production processes. Hydraulic presses shape metal components with forces exceeding thousands of tons, while injection molding machines use hydraulic pressure to form plastic parts with exact specifications. Assembly lines incorporate hydraulic robots that position components within fractions of a millimeter.

Metal stamping operations depend on hydraulic servo presses that deliver full tonnage evenly throughout the stroke. Press brakes use synchronized hydraulic cylinders to bend metal sheets into precise angles for aerospace and automotive parts. The global hydraulics market reached $38.38 billion in 2024, driven largely by industrial automation and manufacturing expansion.

Material handling systems throughout warehouses and factories operate on hydraulic power. Forklifts lift pallets weighing several tons using compact hydraulic cylinders. Conveyor systems adjust height and angle through hydraulic actuators. Industrial cranes generate the force needed to move heavy machinery across factory floors, with some systems capable of lifting loads exceeding 100 tons.

Construction sites showcase some of the most visible applications of hydraulic technology. Excavators use hydraulic cylinders to power their digging arms, buckets, and swing mechanisms. A typical 20-ton excavator like the Volvo EC210 relies on hydraulic pressure around 3,000 psi to break through rock and move earth efficiently.

Bulldozers push massive amounts of material using hydraulic blade control systems. The operator adjusts blade angle and height through hydraulic cylinders that respond instantly to control inputs. Dump trucks utilize hydraulic lift cylinders to raise beds loaded with 20-30 tons of material, with the lifting occurring in under 30 seconds.

Concrete pumps transport mixed concrete to heights of 200 feet or more through hydraulic pressure. Pile drivers use hydraulic force to drive foundation pilings deep into the ground. Tower cranes depend on hydraulic systems for hoisting heavy loads and positioning them with precision at extreme heights.

The construction segment dominates the hydraulic equipment market with approximately 19% market share in 2024, reflecting the sector’s massive infrastructure investments globally. In 2024 alone, U.S. construction spending exceeded $2 trillion, creating sustained demand for hydraulic-powered machinery.

Aircraft hydraulic systems control critical flight functions that determine safety and performance. Commercial airliners operate hydraulic systems at pressures between 3,000 and 5,000 psi to power flight control surfaces, landing gear, and braking systems. The Boeing 747 introduced in 1968 featured a centralized hydraulic system design that remains fundamentally unchanged in modern aircraft.

Flight control surfaces including ailerons, elevators, and rudders respond to pilot inputs through hydraulic actuators. These systems provide the power-to-weight ratio necessary to move large control surfaces against significant aerodynamic forces. A commercial jet’s hydraulic system can generate enough force to deflect wing flaps weighing hundreds of pounds in seconds.

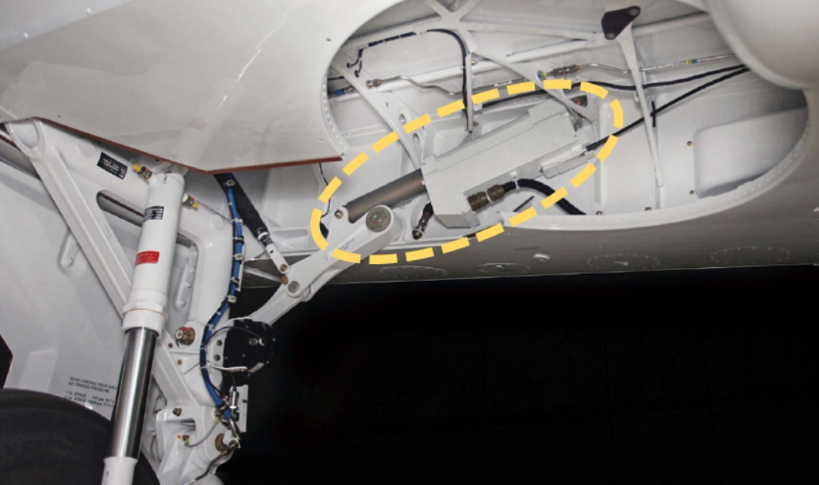

Landing gear operations rely entirely on hydraulic pressure for extension and retraction. The complex mechanism must deploy reliably every flight, with hydraulic systems providing the force to lower gear assemblies weighing thousands of pounds against wind resistance. Backup systems ensure redundancy in case of primary system failure.

Aircraft brakes convert hydraulic pressure into stopping force through multiple disc assemblies. Modern commercial aircraft feature anti-skid systems that modulate hydraulic pressure to each wheel independently, preventing tire damage during landing. The Airbus A320 employs three independent hydraulic systems (Green, Yellow, and Blue) operating at 3,000 psi under normal conditions, with the Ram Air Turbine providing emergency hydraulic power at 2,500 psi.

Cargo doors on large freight aircraft open and close through hydraulic cylinders capable of moving doors weighing several tons. Military aircraft use hydraulic systems for weapons bay doors, arresting hooks, and specialized equipment. The reliability of aviation hydraulics contributed significantly to modern aviation’s safety record, with proper maintenance ensuring consistent performance across millions of flight hours.

Modern farming depends on hydraulic systems to increase productivity and reduce manual labor. Tractors incorporate hydraulics for three-point hitch systems that raise and lower implements weighing thousands of pounds. Hydraulic remotes allow operators to control additional equipment like front-end loaders, backhoes, and post hole diggers from the tractor seat.

Combine harvesters use hydraulic drives for header height adjustment, reel speed control, and unloading augers. The ability to adjust settings hydraulically while harvesting allows operators to adapt quickly to changing field conditions. India recorded sales of over 900,000 tractors in 2023, many integrating advanced hydraulic systems for implements.

Hydraulic sales in agriculture are experiencing rapid growth, with the sector expected to become the second-largest mobile hydraulics market after construction equipment by 2026. Variable-rate technology and autonomous agricultural machinery require responsive hydraulic actuation systems, driving demand for sophisticated components.

Irrigation systems employ hydraulic pumps to deliver water across vast acreages. Sprinkler systems adjust spray patterns through hydraulic controls. Modern precision agriculture equipment uses hydraulic pressure to operate seed planters, fertilizer spreaders, and pesticide applicators with exact control over application rates.

Vehicles of all types integrate hydraulic technology for essential functions. Brake systems convert pedal pressure into stopping force through hydraulic fluid transmission. When a driver presses the brake pedal, hydraulic pressure distributes evenly to all wheels, following Pascal’s Law principles. Modern anti-lock braking systems modulate this pressure hundreds of times per second.

Power steering systems use hydraulic assistance to reduce the effort needed to turn wheels. A hydraulic pump driven by the engine pressurizes fluid that helps move the steering rack. Electric vehicles are increasingly adopting electro-hydraulic steering systems that provide similar assistance with improved efficiency.

Suspension systems in luxury and performance vehicles employ hydraulic or hydro-pneumatic setups that adjust ride height and damping. These systems can raise vehicles for off-road clearance or lower them for improved aerodynamics at highway speeds. Convertible tops operate through hydraulic cylinders that fold and stow roof panels in seconds.

Automotive manufacturing relies extensively on hydraulic presses for stamping body panels, forming chassis components, and assembling powertrains. The precision and repeatability of hydraulic systems enable mass production with consistent quality. Tenneco introduced a hydraulic rebound stop system in June 2024 specifically designed to reduce energy and noise in electric vehicles.

Healthcare facilities use hydraulic systems in equipment that directly impacts patient care and safety. Hospital beds adjust height, backrest angle, and leg position through electro-hydraulic actuators. These systems allow caregivers to position patients ergonomically while ensuring patient comfort. Modern hospital beds can adjust smoothly under loads exceeding 500 pounds.

Operating tables require precise positioning capabilities during surgical procedures. Hydraulic lifting columns enable height adjustment, Trendelenburg and anti-Trendelenburg positioning, and lateral tilt functions. HAWE Micro Fluid’s systems are certified to medical device standards (DIN EN ISO 13485) and power operating tables used in hospitals worldwide.

Patient transport equipment depends on hydraulic technology for safety and efficiency. Emergency stretchers use electro-hydraulic systems to raise and lower patients, significantly reducing musculoskeletal injuries among paramedics. Powered stretchers can lift patients from ground level to ambulance height with minimal physical effort from emergency responders.

Medical imaging equipment including CT scanners and MRI machines uses hydraulic actuators to position patient tables with millimeter-level accuracy. Physical therapy tables adjust through hydraulic controls to accommodate different treatment positions. Dental chairs rely on hydraulic mechanisms for smooth height adjustment and patient positioning.

Surgical robotics systems incorporate precision hydraulic components for tool manipulation. These systems require contamination-resistant designs that operate reliably in sterile environments. The medical hydraulics market continues expanding as global population aging increases healthcare equipment demand.

Mining environments subject equipment to extreme conditions where hydraulic systems provide the durability and power needed. Excavators and shovels used in surface mining rely on hydraulic cylinders to move tons of earth with each scoop. These machines operate continuously in environments with high dust, vibration, and temperature variations.

Drilling equipment uses hydraulic pressure to rotate drill bits and advance them into rock layers. Hydraulic pumps generate the force needed for penetration, while hydraulic motors ensure consistent speed. Hydraulic cylinders adjust drill angle and pressure to adapt to varying rock hardness.

Underground mining equipment depends on hydraulic systems for roof support installation, material transport, and ventilation control. Hydraulic jacks provide the lifting force needed to position roof bolts precisely. The harsh underground environment requires hydraulic components with metal guard rings to minimize contamination.

Haul trucks transport extracted materials using hydraulic lift systems capable of raising beds loaded with 100+ tons. These trucks can complete a lift cycle in under a minute, maximizing operational efficiency. Mining conveyors adjust to terrain changes through hydraulic positioning systems.

The mining industry benefits from hydraulics’ ability to generate massive force for lifting extremely heavy loads. Equipment can multiply input forces to deliver outputs sufficient for moving boulders and drilling through solid rock. Fire-resistant hydraulic fluids specially formulated for mining environments include oxidation inhibitors and anti-wear additives that protect pumps and motors.

Ships and vessels incorporate hydraulic systems throughout their operations. Cargo handling equipment uses hydraulics to lift containers weighing up to 40 tons onto and off vessels. Deck cranes on industrial ships operate through hydraulic power, enabling precise load positioning even in rough seas.

Engine rooms contain hydraulic automatic control systems that regulate valve positions and pneumatic air pressure. These systems ensure efficient engine operation across varying sea conditions. Ship stabilizers prevent rolling through hydraulically-controlled fins that extend from the hull, counteracting wave motion to provide smooth passage.

Steering systems on large vessels require significant force to turn rudders against water resistance. Hydraulic steering gear provides the power needed while allowing responsive control from the bridge. Naval vessels rely on hydraulic systems for critical functions, with components meeting stringent military specifications.

Anchor handling and mooring operations use hydraulic winches capable of managing chains and ropes under tremendous tension. Hydraulic bow thrusters enable ships to maneuver in tight spaces without tug assistance. Submarine systems employ hydraulics for periscope operation, torpedo tube doors, and ballast control.

Theme parks wouldn’t exist in their current form without hydraulic technology. Roller coasters reaching extreme heights use hydraulic systems to ensure safe operation and precise control. Hydraulic cylinders switch track paths, brake cars, and align rides with loading platforms. The accuracy of these systems protects millions of visitors annually.

Theatrical stages employ hydraulics to create dramatic effects during performances. Hydraulic platforms raise and lower stage sections, enabling scene changes and special effects. Cirque du Soleil’s Ka stage features one of the most complex hydraulic configurations ever built for theater, with platforms that move in multiple axes simultaneously.

Simulation rides combine hydraulics with digital controls to create immersive experiences. Motion platforms respond to video content by tilting, rotating, and translating in real-time. These systems must reproduce movements accurately while maintaining passenger safety under varying loads.

Snow removal equipment uses hydraulics to angle plow blades and control salt spreaders. Ski lifts employ hydraulic braking systems for emergency stops. Stadium seating in modern sports venues adjusts through hydraulic mechanisms, allowing venue reconfiguration for different events.

Hydraulic systems appear in unexpected places throughout daily life. Office chairs adjust height through gas springs that function on hydraulic principles. The smooth operation allows users to find comfortable working positions quickly. Barber chairs use hydraulic foot pumps to raise and lower clients during haircuts.

Automotive service centers depend on hydraulic lifts that raise entire vehicles for maintenance access. These lifts can elevate cars weighing 4,000+ pounds to comfortable working height in seconds. The safety locks on hydraulic lifts prevent accidental lowering during service work.

Dishwashers in commercial kitchens incorporate hydraulic systems to increase water pressure for better cleaning performance. These systems operate more quietly than traditional designs while delivering stronger spray action. Hydraulic mechanisms in bakeries lift dough, flip products, and transport goods along conveyor systems for packaging.

Bicycle disc brakes, particularly on mountain bikes, use hydraulic fluid to transmit braking force from levers to calipers. This provides consistent stopping power and better modulation compared to cable-actuated systems. Hydraulic brakes maintain performance even in wet and muddy conditions.

Exercise equipment including leg presses and cable machines often use hydraulic resistance cylinders. These provide smooth, adjustable resistance throughout the full range of motion. Rehabilitation equipment uses hydraulics to create controlled movement patterns for physical therapy.

Petroleum extraction and processing rely extensively on hydraulic systems. Drilling rigs use hydraulic power to rotate drill strings, control drilling mud circulation, and position pipe sections. The precision required for directional drilling depends on hydraulic systems that can adjust drill bit angle while thousands of feet underground.

Hydraulic fracturing operations pump fluid at extreme pressures to fracture rock formations and release trapped hydrocarbons. These systems must generate and sustain pressures exceeding 10,000 psi while pumping millions of gallons of fluid. The equipment operates continuously in remote locations with minimal maintenance opportunities.

Pipeline valves controlling oil and gas flow operate through hydraulic actuators. These valves must respond quickly in emergency situations while handling fluids at high pressure and temperature. Offshore platforms use hydraulic systems for drilling, production equipment, and safety systems including blowout preventers.

Refineries incorporate hydraulics throughout their processes for valve control, material handling, and equipment positioning. The reliability of hydraulic systems in hazardous environments makes them suitable for areas where electrical systems might create ignition risks.

Garbage trucks compress collected waste using hydraulic rams that generate crushing forces exceeding 30 tons. The compaction increases truck capacity by reducing waste volume up to 5:1. Hydraulic lift mechanisms raise bins weighing hundreds of pounds and dump contents automatically.

Recycling facilities use hydraulic balers to compress materials into dense bundles for efficient transport. Aluminum, cardboard, plastic, and paper all undergo hydraulic compression before shipment to processing centers. A single baler can process tons of material per hour through hydraulic pressure.

Waste transfer stations employ hydraulic compactors that push refuse into transport containers. These systems handle diverse materials while maintaining worker safety through enclosed designs. Demolition sites use hydraulic crushing attachments on excavators to reduce concrete and metal structures to recyclable sizes.

Landfill equipment including compactors relies on hydraulic systems to pack waste densely, maximizing site capacity. The heavy-duty hydraulic components withstand the harsh environment filled with abrasive materials and corrosive substances.

The integration of IoT and smart sensors is transforming hydraulic systems into predictive maintenance platforms. Sensors monitor pressure, temperature, and flow in real-time, identifying potential failures before they occur. This connectivity enables remote diagnostics and reduces unexpected downtime across industries.

Electro-hydraulic systems are gaining adoption for their improved efficiency and lower energy consumption. These systems merge hydraulic power with electronic precision, offering superior performance in industrial applications. The global hydraulics market is projected to reach $44.26 billion by 2030, growing at a 2.4% CAGR from 2025.

Biodegradable hydraulic fluids reduce environmental risks in applications where leaks could contaminate soil or water. Synthetic formulations provide better performance across temperature ranges while meeting increasingly strict environmental regulations. California’s Advanced Clean Truck regulation is driving development of hydraulic systems compatible with zero-emission vehicles.

Miniaturization trends enable smaller, more agile hydraulic components without performance sacrifice. These advancements benefit medical devices, robotics, and aerospace applications requiring precise control in confined spaces. Materials science contributes stronger alloys and lightweight composites that improve durability while reducing system weight.

Construction leads hydraulic system usage globally, holding approximately 19% of market share. Manufacturing, agriculture, and aerospace follow as major consumers. The construction sector’s dominance reflects massive infrastructure investments worldwide and the technology’s suitability for heavy equipment applications.

Aircraft hydraulic systems pressurize fluid to 3,000-5,000 psi, transmitting this pressure to actuators controlling flight surfaces, landing gear, and brakes. The systems operate on Pascal’s Law, distributing pressure equally throughout the fluid. Modern commercial aircraft include multiple independent hydraulic systems for redundancy and safety.

Hydraulic systems perform reliably in conditions ranging from arctic cold to desert heat. Aviation hydraulics function at altitudes above 40,000 feet where temperatures drop below -60°F. Mining equipment operates underground in dusty, high-vibration environments. Proper fluid selection and component design enable operation across diverse conditions.

Hydraulic systems use incompressible liquids (typically oil) providing precise control and high force capability. Pneumatic systems use compressed air, offering lighter weight but less force and precise control. Hydraulics excel in heavy lifting and precision positioning, while pneumatics suit rapid cycling applications.

Hydraulic systems permeate modern infrastructure in ways most people never notice. That office chair adjustment, the smooth descent of an elevator, the precision of surgical equipment—all rely on the same fundamental principles discovered centuries ago. The technology continues evolving with smart sensors and eco-friendly fluids, but the core advantage remains: converting fluid pressure into controlled, powerful motion. Industries from farming to space exploration depend on this capability, making hydraulics one of engineering’s most versatile technologies.