Menu

Hydraulic spool valves are manufactured across all major industrial regions, with production concentrated in North America, Europe, and Asia-Pacific. Major producers include Parker Hannifin and Bosch Rexroth in the United States and Germany, along with numerous specialized manufacturers in China, Japan, and South Korea. The global hydraulic valve market reached $8.83 billion in 2024, with spool valves representing a significant portion of directional control valve production that serves construction, manufacturing, oil and gas, and agricultural equipment industries worldwide.

The production of hydraulic spool valves spans multiple continents, with distinct manufacturing hubs emerging based on technological expertise and market proximity. North American facilities dominate high-precision applications, while Asian manufacturers have captured significant market share in cost-competitive segments.

North America accounts for 38.3% of global hydraulic valve market revenue, with the United States hosting major production facilities from companies like Parker Hannifin, Eaton, and Sun Hydraulics. These manufacturers operate state-of-the-art facilities in states including Ohio, Wisconsin, and New Jersey, producing advanced hydraulic directional spool valves for aerospace, defense, and heavy equipment applications. Parker Hannifin’s Hydraulic Valve Division maintains multiple manufacturing centers that produce thousands of valve configurations annually, from standard CETOP-mounted units to custom electrohydraulic systems.

Europe represents another critical production region, led by Germany’s Bosch Rexroth, which manufactures WE series directional spool valves alongside pilot-operated variants. German engineering expertise has positioned the country as a leader in precision hydraulic components, with facilities focusing on automated hydraulic valves that integrate IoT capabilities for real-time system monitoring. Italy, the UK, and France host additional production capacity, with companies like Atos and Walvoil producing specialized valve systems for mobile and industrial hydraulics.

Asia-Pacific has emerged as the fastest-growing production region, projected to expand at 4.1% CAGR through 2030. China leads Asian production with companies like Ningbo Hanshang Hydraulic, Jinan Longli, and QT Hydraulic operating facilities that produce over 300,000 valve units annually. These manufacturers have invested heavily in CNC machining centers and precision grinding equipment to meet international quality standards. Japanese firms including Yuken Kogyo and TAIYO contribute advanced proportional and servo valve technologies, while South Korean manufacturers focus on automotive and construction equipment applications.

Global hyd spool valve production is dominated by a relatively small number of large-scale manufacturers alongside hundreds of specialized regional producers. Parker Hannifin operates as the world’s largest motion and control technology manufacturer, with hydraulic valve production distributed across multiple divisions and global facilities. The company’s product range spans from compact cartridge valves to large sectional directional control valves, with production volumes supporting industries from agriculture to aerospace.

Bosch Rexroth stands as Parker’s primary competitor, manufacturing comprehensive lines of directional spool valves through facilities in Germany, the United States, and Asia. The company’s WE and WH series directional spool valves set industry standards, with some models directly interchangeable with Parker’s D1VW series based on identical CETOP mounting patterns and performance specifications. Rexroth’s production emphasizes pilot-operated configurations for high-flow applications, with pressure ratings extending beyond 350 bar in specialized designs.

Eaton Corporation maintains significant valve manufacturing capacity focused on mobile hydraulics, producing both open-center and closed-center spool configurations for construction and agricultural equipment. The company’s facilities introduced new high-pressure hydraulic valves in 2024 engineered specifically for extreme environments in oil exploration applications, demonstrating ongoing innovation in valve metallurgy and seal technology.

Sun Hydraulics specializes in cartridge-style valves that integrate into custom manifold blocks, offering a modular approach to hydraulic system design. This manufacturing model allows for compact installations with reduced plumbing complexity. Continental Hydraulics, Danfoss, and Vickers round out the major global producers, each maintaining specialized product lines targeting specific market segments.

Chinese manufacturers have rapidly expanded production capabilities, with companies like Target Hydraulics and Hoyea Machinery producing both domestic market supply and export volumes exceeding 10,000 units monthly. These facilities utilize advanced casting and precision machining to produce components competitive with Western manufacturers at lower price points, serving markets in over 60 countries across North America, Europe, Africa, and Southeast Asia.

Modern hydraulic spool valve manufacturing employs precision machining processes to achieve the tight tolerances required for reliable operation. Spool bodies must maintain clearances typically between 5-15 microns from housing bores to minimize internal leakage while allowing smooth movement. This precision demands specialized grinding and honing equipment capable of maintaining surface finishes below 0.4 Ra micrometers.

CNC machining centers form the backbone of contemporary valve production, enabling complex port patterns and mounting interfaces with repeatable accuracy. Five-axis machining allows manufacturers to produce integrated manifolds combining multiple valve functions in single castings, reducing system complexity and potential leak points. Leading facilities operate multiple CNC lines capable of lights-out manufacturing, with automated tool changing and in-process quality verification.

Material selection significantly impacts valve performance and production processes. Most hydraulic spool valve bodies utilize ductile iron or steel alloys chosen for strength, machinability, and wear resistance. Spools themselves typically receive hard chrome plating to resist scoring and extend service life, with coating thickness precisely controlled to maintain critical clearances. Some high-performance applications specify stainless steel construction for corrosion resistance in marine or food processing environments.

Quality control measures span the entire manufacturing process, from incoming material certification through final pressure testing. Major manufacturers maintain ISO 9001 certification as baseline quality management, with many holding additional ISO 14001 environmental certifications. Pressure testing verifies valve integrity at rated working pressures, typically 1.5 times nominal specifications. Flow testing confirms performance characteristics match published specifications across the operating range.

Construction equipment represents the single largest application category for hydraulic spool valves, with excavators, loaders, cranes, and other mobile machinery requiring multiple directional control valves per unit. A typical hydraulic excavator might incorporate 6-12 spool sections controlling boom, stick, bucket, swing, and auxiliary functions. Global construction equipment production drives steady demand for two spool hydraulic control valve systems and more complex multi-section configurations.

Manufacturing and industrial automation increasingly rely on hydraulic systems for press operations, material handling, and production machinery. These applications favor automated hydraulic valves with solenoid or proportional control, allowing integration with programmable logic controllers. The shift toward Industry 4.0 manufacturing has accelerated demand for valves incorporating electronic feedback and diagnostic capabilities.

Agricultural equipment utilizes hydraulic spool valves extensively, from compact tractors to large combines and tillage equipment. Open-center valve systems remain common in agriculture due to their simple operation and lower cost, though closed-center load-sensing systems are gaining market share in premium equipment lines. Seasonal production cycles in agriculture create demand fluctuations that manufacturers accommodate through inventory management and flexible manufacturing.

Oil and gas extraction relies on high-pressure hydraulic valves for drilling equipment, blowout preventers, and well service applications. These demanding environments require valves rated for pressures exceeding 5,000 PSI with materials resistant to corrosive fluids and extreme temperatures. Offshore platform applications add marine environment corrosion resistance requirements, driving specification of stainless steel or special coatings.

Mining equipment presents similar demands to construction but often with higher duty cycles and harsher conditions. Large haul trucks, draglines, and continuous miners depend on robust hydraulic systems controlled by hardened spool valves capable of million-cycle lifetimes. The mining industry’s focus on reliability drives premium pricing for proven valve designs with extensive field history.

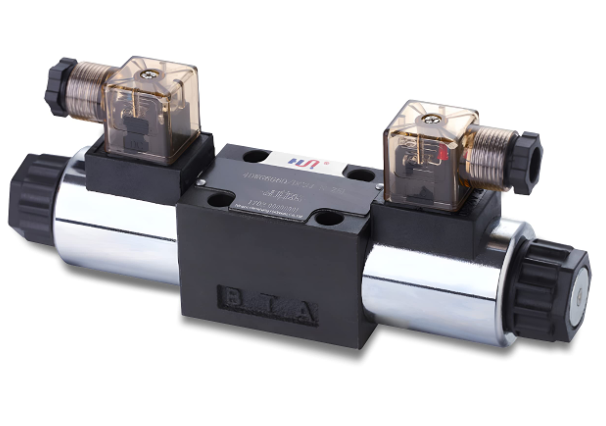

Hydraulic spool valve parts include the valve body casting, precision-ground spool, end caps, seals, springs, and optional solenoid actuators. The spool itself features lands and grooves machined to precise dimensions that control flow paths as the spool translates within the bore. Different spool configurations create varied flow patterns, with designations like “closed center,” “open center,” “tandem center,” and “float center” describing neutral position characteristics.

A typical hydraulic spool valve diagram shows the spool positioned between pressure (P), tank (T), and work (A, B) ports. In neutral position, a closed-center spool blocks all ports, maintaining system pressure. Shifting the spool connects pressure to a work port while connecting the opposite work port to tank, creating directional flow control. Spring return mechanisms automatically center the spool when actuating force releases, providing fail-safe operation.

Flow capacity represents a critical specification, with common ranges from 11 GPM to 32 GPM for mobile applications and higher flows to 80+ GPM for industrial systems. Pressure ratings typically range from 3,000 PSI for standard mobile valves to 5,000+ PSI for industrial applications. Some specialized designs reach 10,000 PSI for ultra-high-pressure systems. Temperature ratings generally span -20°F to 250°F, with extended-range options for extreme environments.

Actuation methods vary based on application requirements. Manual levers provide direct mechanical control preferred in mobile equipment for operator feel and reliability. Hydraulic pilot operation uses system pressure to shift large spools requiring excessive manual force, enabling remote mounting and easier operator interfaces. Solenoid actuation allows electronic control integration, with proportional solenoids enabling infinite positioning between flow extremes rather than simple on/off operation.

The global hydraulic valve market is projected to reach $13.31 billion by 2032, expanding at 6.03% CAGR from 2024 levels. Several factors drive this growth, including increasing automation across industries, infrastructure development in emerging markets, and replacement demand from aging equipment fleets. Automated hydraulic valves are forecast to capture 68.1% of market share by 2034 as industries prioritize efficiency and remote operation capabilities.

Regional growth patterns show Asia-Pacific markets expanding fastest, driven by construction booms in India, Southeast Asia, and continued Chinese infrastructure investment. North America maintains the largest market share due to high equipment values and preference for premium hydraulic components. European markets emphasize energy efficiency and environmental compliance, driving adoption of load-sensing and flow-sharing valve technologies that reduce fuel consumption.

Product innovation focuses on several key areas including miniaturization, electronic integration, and improved energy efficiency. Manufacturers are developing compact valve designs that reduce installation space by 30% while maintaining performance specifications. IoT-enabled valves with embedded sensors monitor operating parameters and predict maintenance requirements, reducing unplanned downtime. Proportional valves with enhanced resolution enable smoother control and reduced energy waste compared to traditional on/off designs.

Supply chain considerations increasingly influence production location decisions. Trade tensions and tariff uncertainties encourage manufacturers to establish regional production capacity serving local markets. Some North American producers have reshored manufacturing from Asia to improve delivery times and avoid import duties. Conversely, Asian manufacturers continue expanding to serve growing domestic markets while maintaining export capabilities to global customers.

Industry standards enable interchangeability between manufacturers’ products, allowing equipment builders and end users flexibility in sourcing. CETOP (European) and NFPA (North American) mounting patterns define bolt hole locations and port positions, ensuring valves from different suppliers can physically interchange. However, internal spool configurations may vary, requiring attention to flow characteristics when substituting brands.

ISO 4401 specifies mounting surface dimensions for directional control valves, with common sizes designated NG06, NG10, and NG16 (corresponding to 3/4″, 1″, and 1.25″ port sizes). These standards facilitate global commerce and simplify maintenance by reducing the variety of mounting interfaces required. Electrical connector standards like DIN 43650 enable solenoid interchange without rewiring.

Cross-reference guides published by suppliers help identify equivalent models between manufacturers. For example, certain Bosch Rexroth WE6 valves directly substitute for Parker D1VW models with identical mounting, port sizing, and flow ratings. However, internal design differences may affect response time, hysteresis, and other performance parameters, making validation testing advisable for critical applications.

Maintaining consistent quality across high-volume production presents ongoing challenges for valve manufacturers. Automated inspection systems using machine vision and laser measurement help detect dimensional variations before out-of-specification parts reach assembly. Statistical process control monitors trends in machining dimensions, enabling corrective action before parts drift outside tolerances.

Supply chain management for raw materials affects production reliability and cost. Steel and aluminum prices fluctuate with commodity markets, requiring manufacturers to maintain strategic inventory or implement flexible pricing arrangements with customers. Some producers operate in-house foundries for casting valve bodies, providing greater control over material quality and delivery schedules.

Workforce development remains challenging as experienced machinists and assembly technicians retire. Leading manufacturers invest in training programs combining classroom instruction with hands-on apprenticeships. Computer-aided manufacturing (CAM) systems help newer employees program CNC equipment more quickly, though setup and troubleshooting still benefit from experience.

Environmental regulations drive changes in manufacturing processes, particularly regarding metal finishing operations like chrome plating and paint application. Many facilities have invested in closed-loop water treatment systems and air quality controls exceeding minimum regulatory requirements. The shift toward water-based hydraulic fluids in some applications influences seal material selections and compatibility testing during valve development.

Spool valves use a cylindrical sliding element to direct flow, offering multiple position capability and generally higher flow capacity than poppet-style valves. The spool design allows proportional control when used with proportional solenoids, making these valves suitable for applications requiring variable speed or force control.

Service life varies dramatically based on application duty cycle and contamination control. Industrial applications with clean fluid and moderate cycling may achieve 10+ years of service, while mobile equipment in harsh environments might require replacement every 2-4 years. Proper filtration extends valve life significantly by preventing abrasive wear between spool and bore.

Some large industrial valves justify rebuilding with new seals and sometimes replacement spools. However, most mobile equipment valves are replaced as complete assemblies due to labor costs exceeding component value. Solenoid coils can often be replaced separately when electrical failures occur without mechanical damage.

Internal leakage results from wear increasing clearance between spool lands and bore, scoring of precision surfaces from contamination, or seal deterioration from heat or chemical exposure. Systems with poor filtration or those operating at high temperatures experience accelerated wear rates. Some leakage is normal and specified by manufacturers, but excessive leakage causes slow actuator movement and heat generation.

The worldwide production of hydraulic spool valves reflects a mature but evolving industry serving critical functions across numerous equipment categories. While established manufacturers maintain dominant market positions through engineering expertise and established distribution networks, emerging producers continue gaining market share through competitive pricing and improving quality standards. Ongoing innovation in electronic control integration and energy efficiency positions hydraulic systems to remain relevant despite competition from electric actuators in some applications. The geographic distribution of production capacity continues adapting to changing trade policies and regional demand patterns, with growth particularly strong in Asian markets supporting local construction and manufacturing expansion.