Menu

A hydraulic diverter valve can handle corrosive fluids when constructed with appropriate materials and protective measures. Standard valves use stainless steel grades 304 or 316, specialized alloys, or corrosion-resistant plastics like PVDF and PVC. The key lies in matching the valve body material, internal components, and seal materials to the specific corrosive media being handled.

The foundation of corrosion resistance in hydraulic diverter valves starts with proper material selection. Different corrosive environments demand specific material responses.

Stainless steel 316 remains the industry standard for highly corrosive and high-pressure environments. This grade contains molybdenum, which provides superior pitting resistance and performs well against chlorides, acids, and marine environments. For mildly corrosive applications, stainless steel 304 offers adequate protection at a lower cost. The choice between these grades depends on corrosive media concentration, operating temperature, and pressure requirements.

For extreme chemical exposure, specialized alloys outperform standard stainless steel. Inconel and Hastelloy alloys provide exceptional resistance to oxidizing acids, reducing acids, and high-temperature corrosive environments. These nickel-based alloys maintain structural integrity where standard materials would fail. Duplex stainless steels combine the strength of ferritic steel with the corrosion resistance of austenitic grades, making them suitable for harsh industrial applications involving both mechanical stress and chemical attack.

Thermoplastic valves represent a cost-effective solution for specific corrosive applications. PVC handles most acids and alkalis at temperatures below 60°C, while PVDF extends chemical resistance to higher temperatures and broader chemical ranges. These non-metallic options eliminate electrochemical corrosion entirely, though they cannot match the pressure ratings of metal valves. Brass components with less than 15% zinc content resist dezincification in water systems, but they require careful selection based on the specific chemicals present.

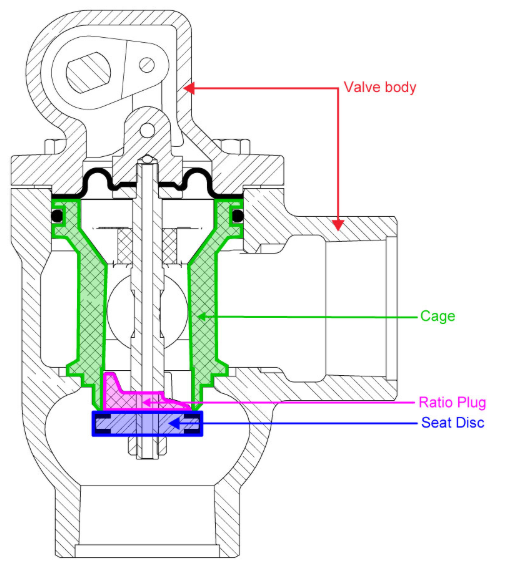

The internal components—spools, seats, and springs—require equal attention to material selection. Hardened and ground steel components may need specialized coatings or alternative materials when exposed to corrosive media. Chrome plating provides a wear-resistant and corrosion-resistant surface for moving parts, extending component life in demanding environments.

Seal failure causes most corrosion-related valve problems. The elastomer or plastic material must resist chemical attack while maintaining flexibility and sealing properties.

Nitrile rubber (Buna-N) works well with mineral oil-based hydraulic fluids but degrades rapidly when exposed to phosphate esters or certain synthetic fluids. This material remains the standard choice for conventional hydraulic systems using petroleum-based fluids. However, switching to biodegradable or fire-resistant fluids requires seal material changes.

Viton (FKM) offers broader chemical resistance, handling petroleum products, synthetic hydraulic fluids, and many acids. This fluoroelastomer maintains sealing performance at elevated temperatures up to 200°C. The material costs more than nitrile but provides longer service life in chemically aggressive environments. EPDM seals excel with water-based and glycol-based fluids but fail quickly in petroleum oils.

PTFE (Teflon) seals provide universal chemical resistance. This material withstands virtually all chemicals at temperatures from -200°C to 260°C. PTFE works in applications where other seal materials cannot survive, though its mechanical properties require careful design consideration. The material’s low friction coefficient reduces wear in dynamic applications.

Seal swelling or shrinking indicates incompatibility between the hydraulic fluid and seal material. Swollen seals bind in their grooves, while shrunken seals leak. Regular inspection detects these issues before they cause system failure. Manufacturers provide compatibility charts matching seal materials to specific hydraulic fluids and chemical exposures.

Surface treatments create barriers between the corrosive environment and the base metal, extending valve life significantly.

Epoxy coatings form a chemical-resistant layer that protects valve bodies from rust and corrosion. Applied as a liquid and cured to form a tough shield, these coatings work well in chemical processing and water treatment applications. The coating thickness and cure process determine the protection level achieved.

Zinc coatings applied through hot-dip galvanizing or electroplating provide sacrificial protection. The zinc corrodes preferentially, protecting the underlying steel. This approach works particularly well for external surfaces and fittings exposed to atmospheric corrosion or marine environments. Nickel plating offers similar cathodic protection with higher tensile strength.

Ceramic coatings handle high-temperature and chemically corrosive environments where organic coatings fail. These coatings demonstrate extreme durability against wear and chemical erosion. The application process requires specialized equipment, but the resulting protection justifies the cost in severe service conditions.

Anodizing thickens the natural oxide layer on aluminum components, improving corrosion resistance and wear properties. This electrochemical process creates a hard, porous oxide layer that can be sealed or colored. Anodized aluminum valves perform well in applications requiring light weight combined with corrosion resistance.

Hydraulic diverter valves redirect fluid flow between multiple circuits, and their configuration affects corrosion vulnerability.

A 2 way hydraulic diverter valve controls flow between two paths, operating in a simple on-off or A-B selection mode. These valves minimize the number of sealing surfaces exposed to corrosive media, reducing potential leak points. The straightforward design simplifies maintenance and material selection for corrosive applications.

A 3 way hydraulic diverter valve adds complexity and functionality, directing flow from one inlet to two outlets or combining two inlets to one outlet. The T-port design allows all three ports open simultaneously, while L-port configurations provide either-or switching. More internal passages mean more surfaces exposed to corrosive fluids, requiring comprehensive material selection across all wetted components.

Six-way solenoid diverter valves control two separate double-acting circuits from a single directional control valve. These complex units reduce system size and piping complexity but present challenges in corrosive environments due to multiple internal flow paths and seal points. Each passage requires proper material selection and seal compatibility.

Electrical actuation systems must withstand corrosive environments while providing reliable switching.

A 12v hydraulic diverter valve dominates mobile and agricultural applications where vehicle electrical systems operate at 12 volts DC. These solenoid-operated valves switch hydraulic flow on electrical command, eliminating manual lever operation. The 12 volt hydraulic diverter valve design must protect the solenoid coil from moisture and chemical exposure through proper sealing and coating.

The 12 volt hydraulic diverter valve 12v versions typically feature IP69 protection ratings for the coil assembly, withstanding high-pressure washdowns and wet environments. Coil temperatures can reach 180°C during continuous operation, requiring heat-resistant insulation materials. The duty cycle specification—often 100% for continuous operation—determines thermal design requirements.

Twenty-four volt versions serve industrial and heavy equipment applications with higher voltage electrical systems. These units generate stronger magnetic forces, allowing control of larger flow rates and higher pressures. The principle differences from 12V units involve coil design and electrical requirements rather than hydraulic performance.

Rocker switches, toggle switches, or momentary pushbuttons control valve actuation. Switch placement on joysticks or control panels affects operator convenience. Momentary switches suit grapple applications where the operator wants automatic return to the primary circuit when releasing the button. Toggle switches work better for extended auxiliary function operation.

Agricultural equipment presents unique corrosive challenges through fertilizer exposure, manure handling, and outdoor operation.

A hydraulic diverter valve for tractor applications diverts loader bucket tilt and curl functions to auxiliary circuits for grapples, forks, or other implements. Mounting locations on the loader arm expose the valve to weather, chemical spray, and mechanical impact. Protective housings and robust construction prove essential for reliable operation.

Tractor hydraulic systems typically operate at 13 to 30 GPM flow rates with pressures reaching 3,000 to 3,600 PSI. The valve must handle these specifications while resisting fertilizer runoff, which contains nitrogen compounds, phosphates, and potassium salts. These agricultural chemicals cause rapid corrosion of unprotected steel components.

Installation positions the valve in-line with existing hydraulic circuits, requiring compatible thread types (SAE or BSPP) and appropriate hose sizes. SAE #8 (3/4″-16) and #12 (1-1/16″-12) threads dominate tractor applications. Mixing thread standards during installation creates leak paths and potential contamination entry points.

Front-end loader modifications for auxiliary functions represent the most common tractor diverter valve application. The operator switches between bucket tilt and implement operation using a dash-mounted or joystick-mounted control. This setup eliminates the need for separate hydraulic circuits while maintaining full bucket functionality.

Hydraulic selector valves represent a specific category of diverter valves optimized for switching between predetermined circuit paths.

These valves feature detent positions that maintain flow direction without continuous electrical input. Spring-return designs automatically switch back to the primary circuit when power stops, while detented versions hold the selected position until commanded to change. The choice depends on application requirements and safety considerations.

Rotary selector valves use a cylindrical or disc-shaped rotator to direct flow. Cast iron construction with hard chrome plated rotors provides durability and corrosion resistance. The rotary design minimizes internal turbulence and pressure drop compared to spool-type valves. Open-center and closed-center configurations suit different hydraulic system designs.

Stackable selector valves allow system expansion by adding sections. Each section controls an additional circuit, permitting control of up to four or five separate functions from a single control point. The modular design simplifies maintenance—a failed section can be replaced without changing the entire valve assembly. Stacking multiple sections increases overall length and weight, affecting mounting considerations.

Hydraulic switch valves operate on similar principles to diverter valves but focus on rapid on-off switching rather than gradual flow control.

These valves use electromagnetic solenoids to move internal spools or poppets almost instantaneously. Switching frequencies can reach 15,000 cycles per hour in some designs. This rapid actuation suits applications requiring quick function changes, such as switching between tool operations on construction equipment.

The internal valve structure determines switching characteristics. Poppet-type valves provide tight shutoff with minimal leakage, using spring-loaded seats that seal under pressure. Spool valves offer faster response and handle higher flow rates but may experience slight leakage past the spool lands. The application determines which design proves more suitable.

Pressure spikes during rapid switching can damage system components if not properly managed. Pressure relief valves and accumulator integration moderate these transients. Some switch valve designs incorporate internal relief passages to protect against trapped pressure during transition.

Preventing corrosion extends valve life and maintains system performance beyond material selection alone.

Regular fluid analysis detects contamination before it causes damage. Water content should remain below 0.05% (500 ppm) in hydraulic oil. Higher water levels accelerate corrosion by promoting acid formation and directly attacking metal surfaces. Filtration systems with coalescers remove water droplets before they enter valve internals.

Fluid oxidation produces acids that attack protective additives and metal surfaces. Anti-oxidant additives slow this process, but thermal stress from high operating temperatures accelerates oxidation regardless. Installing oil coolers maintains optimal fluid temperature, preserving additive packages and reducing corrosion rates.

Breather filters prevent atmospheric moisture and contaminants from entering the hydraulic reservoir. Desiccant-type breathers remove water vapor from incoming air during system cooling cycles. This simple addition dramatically reduces water contamination in mobile equipment operating in humid environments.

Maintenance schedules should include visual inspection of external valve surfaces for corrosion initiation. Surface rust on external fasteners or housings indicates moisture exposure that may affect internal components. Early detection allows corrective action before internal damage occurs.

Flushing systems thoroughly before switching hydraulic fluid types prevents incompatibility reactions. Residual mineral oil mixed with synthetic or water-based fluids can form sludge or break down corrosion inhibitors. Complete fluid changes with proper flushing procedures maintain system integrity.

The broader hydraulic valves system context influences corrosion management strategies for diverter valves.

System design should minimize fluid velocity through valves to reduce erosion-corrosion. Flow velocities above 20 feet per second cause cavitation and erosive wear, accelerating material loss even in corrosion-resistant materials. Proper pipe sizing and valve port selection control flow velocity within acceptable ranges.

Pressure drops across the valve convert hydraulic energy to heat. Excessive pressure drops indicate restriction, which generates higher fluid temperatures and accelerates both oxidation and corrosion. Selecting valves with appropriate flow capacities minimizes pressure drop and thermal stress.

Contamination control throughout the hydraulic system protects valves from particulate-induced wear that exposes fresh metal surfaces to corrosive attack. ISO 4406 cleanliness standards specify maximum particle counts by size. Maintaining cleanliness levels appropriate for the valve type prevents accelerated wear and subsequent corrosion.

Chemical compatibility extends beyond the valve to include all system components—hoses, fittings, cylinders, and pumps. A single incompatible component can contaminate the entire system with degradation products that attack other components. System-wide compatibility analysis prevents these cascade failures.

Ongoing performance monitoring detects corrosion before it causes valve failure.

Pressure testing verifies valve sealing performance. A gradual pressure drop in the isolated circuit indicates internal leakage, possibly from corrosion-damaged seats or worn seals. Establishing baseline pressure hold times when the valve is new provides comparison data for detecting degradation.

Switching time measurements reveal wear in solenoid-operated valves. Corroded spools bind in their bores, increasing actuation time. Monitoring switch time trends identifies developing problems before complete failure occurs.

External leakage around shaft seals or body joints indicates seal degradation or corrosion breakthrough. Even minor weeping should prompt investigation, as corrosive fluids migrate through tiny openings and attack surrounding components.

Temperature monitoring detects abnormal heat generation from increased friction due to corrosion products or contamination. Thermal imaging identifies hot spots before mechanical failure occurs.

Fluid samples analyzed for wear metals provide early warning of corrosion. Elevated iron, copper, or chromium levels indicate material loss from valve internals. Trending these measurements over time reveals accelerating corrosion before visible damage appears.

Stainless steel 316 provides excellent general-purpose corrosion resistance for most hydraulic applications. For extreme chemical exposure, Hastelloy or Inconel alloys offer superior protection. Thermoplastic valves using PVDF resist a broad chemical range at lower pressures and temperatures. Material selection must match the specific corrosive media, temperature, and pressure conditions in your application.

Standard valves using carbon steel or aluminum construction will fail rapidly in acidic environments. Acids attack these materials directly, causing rapid degradation. Acidic fluid applications require either stainless steel construction or specialized corrosion-resistant alloys. The pH level and acid concentration determine the minimum material grade required for reliable operation.

Install desiccant breather filters on hydraulic reservoirs to remove water vapor from incoming air. Maintain fluid temperature below levels that promote water absorption. Use hydraulic fluids with robust rust inhibitors that form protective films on metal surfaces. Regular fluid analysis detects water contamination early, allowing corrective action before corrosion damage occurs.

Chemical incompatibility between the seal material and hydraulic fluid causes swelling, hardening, or cracking. Corrosive media can attack seal compounds directly, breaking down the polymer structure. Elevated temperatures accelerate chemical reactions between fluids and seals. Selecting seal materials specifically compatible with your hydraulic fluid prevents these failures.

Corrosion protection in hydraulic diverter valves requires comprehensive attention to materials, coatings, seals, and maintenance practices. The specific corrosive environment dictates which protection strategies prove most effective. Chemical compatibility testing before system design prevents costly failures after installation.

Material selection forms the foundation—stainless steel alloys for general protection, specialized alloys for extreme conditions, or engineered plastics where appropriate. Protective coatings extend the capability of base materials into more aggressive environments. Proper seal selection prevents leakage and contamination entry.

Regular maintenance including fluid analysis, visual inspection, and performance monitoring detects developing problems early. Proactive replacement of degraded components costs less than repairing catastrophic failures. The investment in corrosion-resistant materials and proper maintenance pays dividends through extended service life and reliable operation.