Menu

Plate-type valves are fixed to the bottom plate with bolts. The pipe connection ports are not made on the valve, but on the bottom plate. Therefore, when replacing the valve, there is no need to disassemble the pipeline, which is much more convenient than cartridge-type or sandwich-type, and can greatly save time and cost.

The standardization progress of plate-type connections has been relatively smooth: pressure valves —— mounting surfaces adopt ISO 5781 standard, relief valves —— mounting surfaces adopt ISO 6264 standard, flow valves —— mounting surfaces adopt ISO 6263 standard, servo valves —— mounting surfaces adopt ISO 10372 standard, especially directional control valves —— mounting surfaces adopt ISO 4401 (GB/T 2514) standard which is widely used worldwide, ensuring interchangeability. For users, the standardization of plate-type connections increases selectivity, but suppliers’ profits have been squeezed to almost the last penny.

NG is the nominal size of the connection hole, not the actual size.

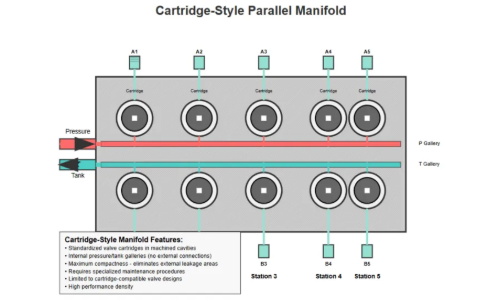

What is more important for the development of hydraulic technology with plate-type connections is the use of manifold blocks: when the system requires multiple plate-type valves, they can be mounted on the same connection block —— manifold block, sharing supply oil and return oil, with interconnecting oil passages made inside the block, replacing pipelines, and the total volume is much smaller, which laid the foundation for subsequent development into integrated blocks.

With manifold blocks, in addition to the advantages of plate-type valves —— valves are fixed to the manifold block with bolts, and there is no need to disassemble pipelines when replacing valves —— being continued, also because there are fewer connecting pipes and corresponding pipe fittings, so:

Since the 1990s, due to the popularization of 3D design software and CNC machining centers, the bottleneck of manifold block design and manufacturing technology has been broken through, creating extremely favorable conditions for the design and processing of complex manifold blocks, shortening delivery time and reducing manufacturing costs.

Manifold blocks use the block’s surface to mount valves, with only connecting passages inside the block. In complex systems with multiple valves, it is necessary to increase the block’s surface area, that is, enlarge the block body. The larger the manifold block, the longer the internal connecting holes, and the cost of drilling deep holes increases not linearly but parabolically with hole depth.

Stack valves are the extension, expansion and integration of plate-type valves in height.

Generally, one stack controls one group of actuators, can achieve complex functions, and is very flexible and easy to replace and modify. Using stack valves can alleviate to a certain extent the problems of large volume and need to process deep holes in pure plate-type valve manifold blocks, but the possible leakage points have increased.