Menu

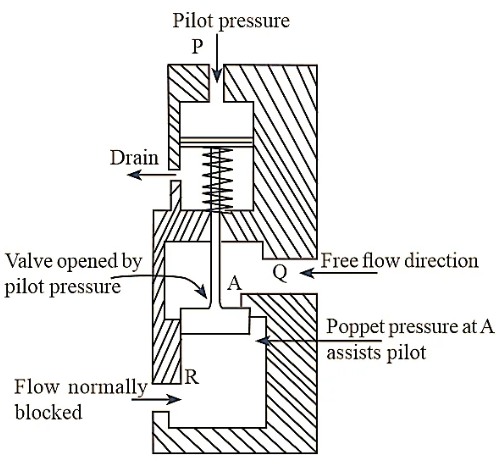

A pilot-operated check valve is a type of on-off valve. It typically has two flow ports (ports ① and ②) and one control port (port ③). The valve spool is initially constrained by port pressure, allowing only unidirectional flow; whether reverse flow is permitted depends on the pressure at the control port.

Because the spring preload force F_T acts on the check valve spool, with the reverse effective area being A₁, the spring preload pressure p_T = F_T/A₁.

Hydraulic valves with different structures exhibit significantly different performance characteristics.

The following is a complete circuit: when the hydraulic cylinder should not move (directional valve in neutral position), the control pressure port B should be connected to tank for unloading to ensure reliable closure of the pilot-operated check valve.

To reduce piping and improve safety, pilot-operated check valves are often mounted in valve blocks, directly attached to the hydraulic cylinder outlet (or even installed in the outlet fitting).

If the hydraulic cylinder is subject to bidirectional external forces when the directional valve is in neutral position, a dual pilot-operated check valve is needed to prevent movement.

Grouped hydraulic cylinders should not be controlled separately by individual pilot-operated check valves: the check valve at the outlet of the cylinder with slightly lower load will open first, causing the entire load to concentrate on the other cylinder, raising the opening pressure, and possibly causing jamming; this issue can be avoided by using a proper circuit design.

Pilot-operated check valves cannot lock motors (motors have internal leakage).

1) Control Ratio and Opening Pressure:

The effective area of control port ③ pressure p₃ is A₃, the effective area of port ① pressure p₁ is A₁, and the ratio K_C = A₃/A₁ (called the control ratio, typically K_C > 1) is the key parameter of the pilot-operated check valve.

Ignoring friction force, the force balance on the check valve spool is:

p₃A₃ + p₂A₁ = F_T + p₁A₁ + p₂A₃

If p₂ is negligible, this simplifies to:

p₃A₃ = F_T + p₁A₁

The condition for opening the flow path is:

p₃ > (F_T + p₁A₁)/A₃ = (p_T + p₁)/K_C

In the characteristic curve, the slope is the control ratio K_C; the higher p₁, the greater the p₃ required for opening.

2) Relationship Between Hydraulic Cylinder Load Force and Chamber Pressures:

The load force F_L affects the pressures in both chambers of the hydraulic cylinder. At steady state, the force balance is:

p_A A_A = p_B A_B + F_L

This can be rewritten as:

p_A = p_B K_A + p_L (7-1)

Where: K_A = A_B/A_A (area ratio of the two chambers of the hydraulic cylinder); p_L = F_L/A_A (load pressure).

See Reference [14] Section 1.4 for detailed characteristic curves of hydraulic cylinders under various area ratios and load forces.

3) Combination of Pilot-Operated Check Valve and Hydraulic Cylinder:

In the combined circuit, the pilot-operated check valve port ① pressure p₁ = p_A (lower chamber of hydraulic cylinder), control pressure p₃ = p_B (upper chamber of hydraulic cylinder). When characteristic curves are combined:

If K_C = K_A, the two characteristic curves are parallel, and the pilot-operated check valve will never open.

4) High-Pressure Lock Problem:

Even if K_C > K_A, if K_C is small and K_A is large, the intersection may exceed the system’s allowable pressure range, causing the valve to fail to open in practice; ordinary pilot-operated check valves have no relief function, so sealed chamber pressure cannot be released.

Improvement for high-pressure lock: Use pilot-operated check valves with high control ratios (K_C = 1~4, up to 6 in some cases), with adequate design margin.

Pilot-operated check valves are on-off valves (fully open when open, with low flow resistance), not suitable for applications with long strokes, large/fluctuating negative loads:

When the valve opens, flow resistance is low; if p_L is high, flow rate is large and the cylinder descends quickly; if the upper chamber flow is insufficient, p_B cannot be maintained at steady-state, causing p₃ to drop and the valve to close, resulting in repeated opening and closing that causes vibration.

Improvement: Install a pilot-operated throttle check valve at port A to maintain p_A ≥ p₁G; however, “opening jump” may still occur, which can be improved with a pre-relief type pilot-operated check valve.

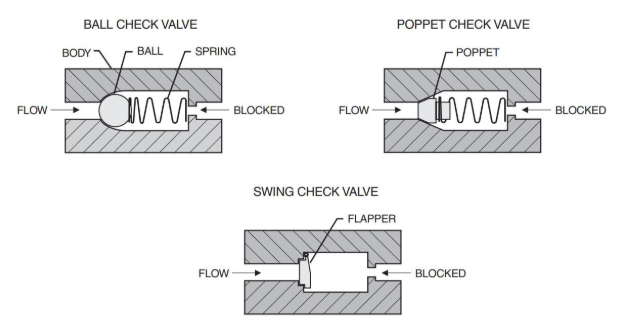

Pilot-operated check valves come in ball valve and poppet valve types.

1) Pre-Relief Type: The control piston first pushes a steel ball for pre-relief, then pushes the main spool, avoiding opening jump.

2) External Control Piston Type: The control piston is mounted in the valve block and can be combined with an ordinary check valve, reducing cost (requires precision machining of the valve block).

3) Dual Pilot-Operated Opening Type: Four flow ports, controlling both chambers of the hydraulic cylinder; external control piston type can also achieve dual pilot-operated opening.

4) Pilot-Operated Closing Type: Functions as an ordinary check valve without control pressure; closes the flow path (no flow in either direction) when control pressure is applied, suitable for regenerative circuits.

5) Pilot-Operated Opening/Closing Type: Two control ports, enabling opening/closing through external pressure.