Menu

Axial piston pumps convert rotational motion into hydraulic fluid flow through a series of pistons arranged parallel to the drive shaft. The design emerged from early 20th-century engineering efforts to create compact, high-pressure hydraulic systems for industrial and military applications. Today these pumps dominate markets ranging from construction equipment to commercial aircraft.

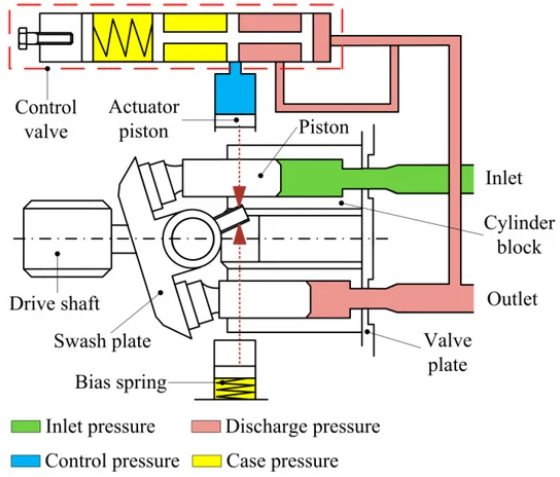

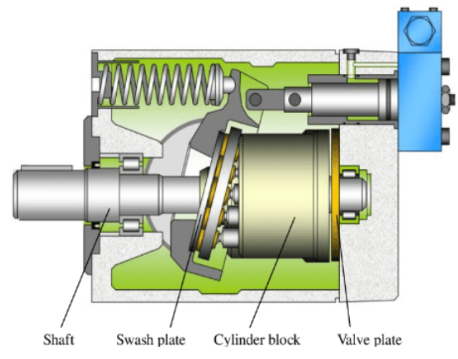

The swashplate configuration represents the most widely manufactured type. Pistons ride in a cylinder block that rotates with the input shaft. A stationary angled plate—the swashplate—causes each piston to reciprocate as the block turns. Adjusting the swashplate angle changes the piston stroke length, enabling variable displacement without altering shaft speed. Bosch Rexroth, Parker Hannifin, and Danfoss all produce swashplate variants rated for continuous operation at 350 to 420 bar.

The bent-axis design takes a different approach. The cylinder block sits at an angle to the drive shaft, typically between 25 and 40 degrees. Pistons connect to the drive flange through ball joints. This geometry produces a stroking action as the block rotates. Bent-axis pumps generally achieve volumetric efficiencies of 96% to 98% at rated pressure, compared with 93% to 95% for comparable swashplate units. The efficiency advantage comes at a cost: bent-axis pumps require more complex bearing arrangements and occupy larger envelopes.

Piston count varies by application. Seven and nine pistons appear most frequently in mobile hydraulics, where odd numbers reduce flow pulsation. Industrial units sometimes use ten or eleven pistons when smoother flow characteristics justify the added manufacturing complexity.

Port plate design determines much of a pump’s durability. The interface between the rotating cylinder block and the stationary port plate sees the highest wear rates. Bronze alloy port plates paired with case-hardened steel cylinder blocks remain standard in medium-duty applications. High-pressure aerospace units increasingly use hydrostatic bearing arrangements that maintain a controlled oil film between the surfaces.

Displacement ranges span from under 10 cubic centimeters per revolution in small servo applications to over 500 cubic centimeters per revolution in heavy mobile equipment. Caterpillar’s largest mining trucks use axial piston pumps delivering more than 600 liters per minute at system pressures exceeding 300 bar.

Operating speed limits depend heavily on lubrication and cooling. Most industrial pumps specify maximum input speeds between 2000 and 4000 rpm. The cylinder block’s rotational velocity creates centrifugal loads on the pistons and slippers. At excessive speeds, the slipper shoes lose contact with the swashplate, causing rapid wear and potential seizure.

Aerospace applications pushed development of pressure-compensated controls during the 1950s and 1960s. These systems automatically reduce displacement as system pressure approaches a set limit, preventing stall conditions and reducing power demand. Modern aircraft like the Boeing 787 use axial piston pumps operating at 350 bar nominal pressure with compensation set points around 380 bar.

Noise generation remains a persistent engineering challenge. Pressure ripple from discrete piston pumping events produces characteristic frequencies related to shaft speed and piston count. A nine-piston pump running at 1800 rpm generates primary flow pulsations at 270 Hz. Manufacturers address noise through various strategies: pre-compression volumes, timing grooves in port plates, and damped case structures.

Contamination sensitivity separates axial piston pumps from simpler gear and vane types. Clearances between pistons and bores typically measure 10 to 20 micrometers. Particles larger than these gaps cause scoring and accelerated wear. ISO cleanliness codes of 18/16/13 or better are standard specifications for axial piston pump circuits.

Recent development efforts focus on electrohydraulic integration. Eaton and Moog have introduced pumps with embedded electronics that combine displacement control, pressure sensing, and communication interfaces in single housings. These units support CAN bus and Ethernet protocols for integration with machine control systems.

Manufacturing tolerances determine final performance. Piston-to-bore clearances, swashplate surface finish, and port plate flatness all require precision grinding and lapping operations. Production costs for axial piston pumps run three to five times higher than equivalent-flow gear pumps. The performance advantages—higher pressure ratings, variable displacement capability, and superior efficiency—justify the premium in applications where power density matters.