Menu

A fleet manager called us last month with a frustrating problem. His 30-ton excavator couldn’t swing and travel at the same time without the whole machine bogging down. Turns out, someone had spec’d a cheap open center valve on a machine that desperately needed load sensing. Productivity dropped 40% before they figured out what was wrong.

That’s why we put this guide together. The Excavator Main Control Valve you choose affects everything—fuel burn, cycle times, operator comfort, maintenance costs. Pick the wrong one and you’re bleeding money. Pick the right one and you might not think about it for 10,000 hours.

Here’s what actually matters when you’re deciding between open center, closed center, and load sensing systems.

Before getting into the technical breakdown, worth sharing what goes wrong when people get this decision backwards.

Mistake #1: “Big technology on small machine”

Customer runs a grapple loader doing forestry work. Machine weighs 8 tons, does simple repetitive cycles. Someone sold them on a full load sensing system because “it’s more efficient.”

What happened: The LS pump’s pressure compensator was constantly hunting because the loads were too light and variable. Oil temperature ran hot. The system felt twitchy. They ended up paying more in fuel than an open center setup would have cost because the pump never settled into an efficient operating point.

The margin pressure on an LS system—that 15-25 bar differential the pump maintains—becomes wasted energy when your actual loads barely exceed it. For lightweight, simple-cycle machines, that “efficiency” works against you.

Mistake #2: “Saving money on the wrong component”

We mentioned the 30-ton excavator at the top. Here’s more detail on what went wrong.

The original equipment had a basic open center valve with series-connected sections. When the operator tried to swing the cab while traveling, the upstream travel section consumed available flow and starved the swing motor downstream.

Result: The machine couldn’t coordinate movement. Jobs that should have taken 8 hours stretched to 12. Fuel consumption per cubic meter of material moved actually increased because the machine spent more time doing less work.

Replacing that valve with a proper LS setup cost $22,000 including installation. But productivity jumped 35% and fuel consumption per unit of work dropped 18%. Payback took about 14 months.

The main control valve is basically the traffic cop for your hydraulic system. Oil comes in from the pump, and the valve decides where it goes—boom cylinder, arm cylinder, swing motor, travel motors. Move a joystick, and the valve routes pressurized fluid to make things happen.

Simple concept. But the way different valve types manage that oil flow? That’s where things get interesting.

Open center is the oldest approach and honestly, it still makes sense for a lot of applications.

Here’s how it works: oil flows continuously through the valve whenever the engine runs. All spools in neutral? Oil passes straight through and dumps back to tank at low pressure. Stroke a spool and that flow redirects to your work port. Release the spool, flow goes back through center.

Why people still use it:

The system is dead simple. Gear pumps are cheap and robust. Any hydraulic tech can troubleshoot it. When you connect or disconnect attachments, air bleeds out naturally because oil is always circulating. For a 12-ton machine doing basic dig-and-dump work, open center handles the job without drama.

Where it falls short:

That constant oil circulation burns fuel even when you’re just sitting there. And here’s the bigger issue—when you try running multiple functions at once, they fight for flow. The valve sections are plumbed in series, so if you’re swinging hard while trying to curl the bucket, something’s going to starve.

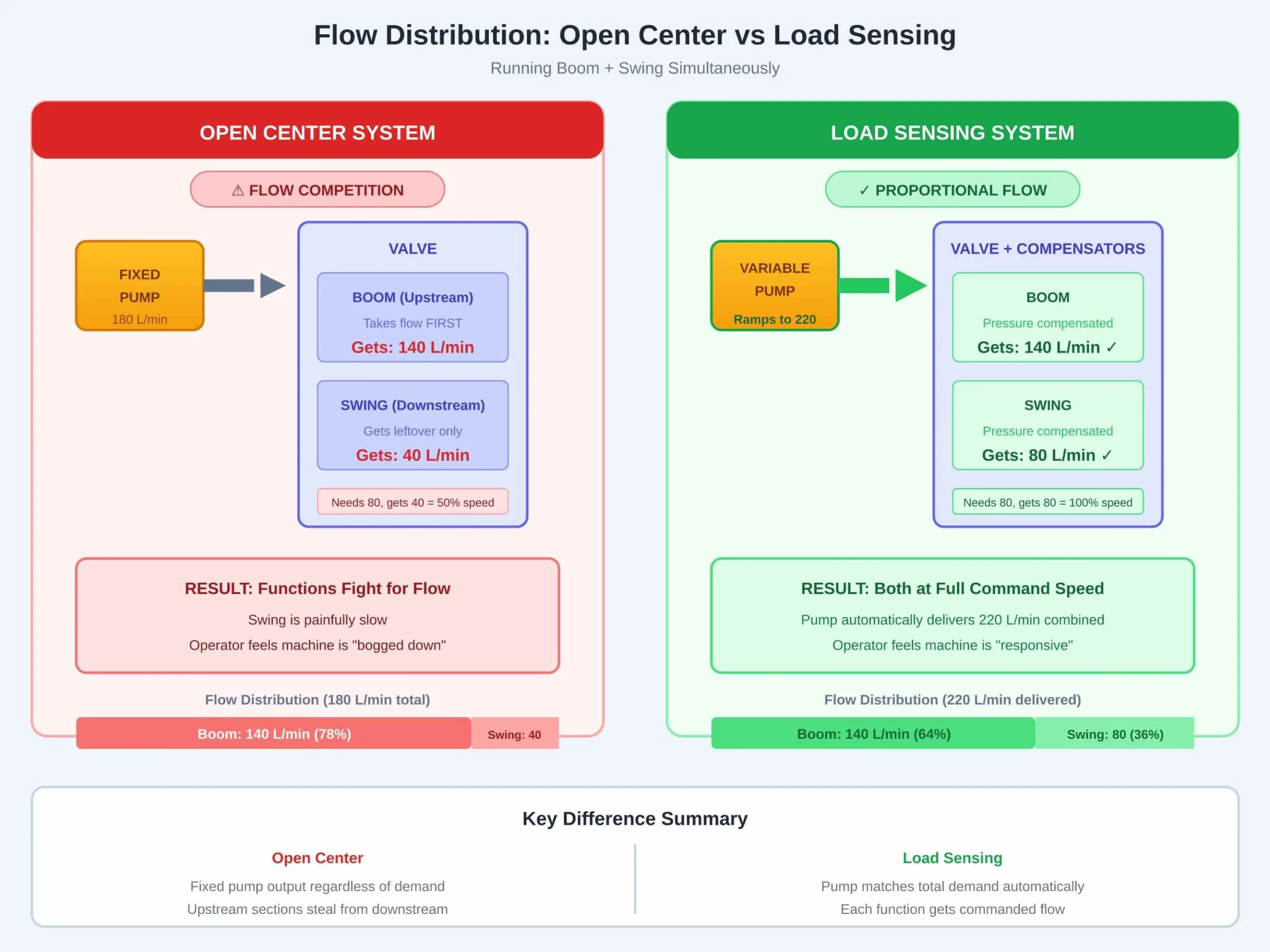

Here’s the difference in action. On the left, an open center system trying to run boom and swing simultaneously. The boom section sits upstream in the valve, so it takes flow first—140 L/min out of 180 available. Swing, sitting downstream, gets the leftover 40 L/min when it actually needs 80. Result: swing is painfully slow, and the operator feels like the machine is “bogged down.

We see this all the time on machines that get retrofitted with thumbs or tilting buckets. The original open center system wasn’t sized for another function, and suddenly operators are complaining that everything feels sluggish.

Load sensing flips the script on how excavator hydraulics work.

Instead of constant flow, an LS system only produces what you need, when you need it. The pump watches the highest load pressure across all active functions and maintains just enough pressure above that to keep oil moving at your commanded rate. Valve spool cracked open a little? You get a little flow. Spool wide open? Pump ramps up to deliver full flow.

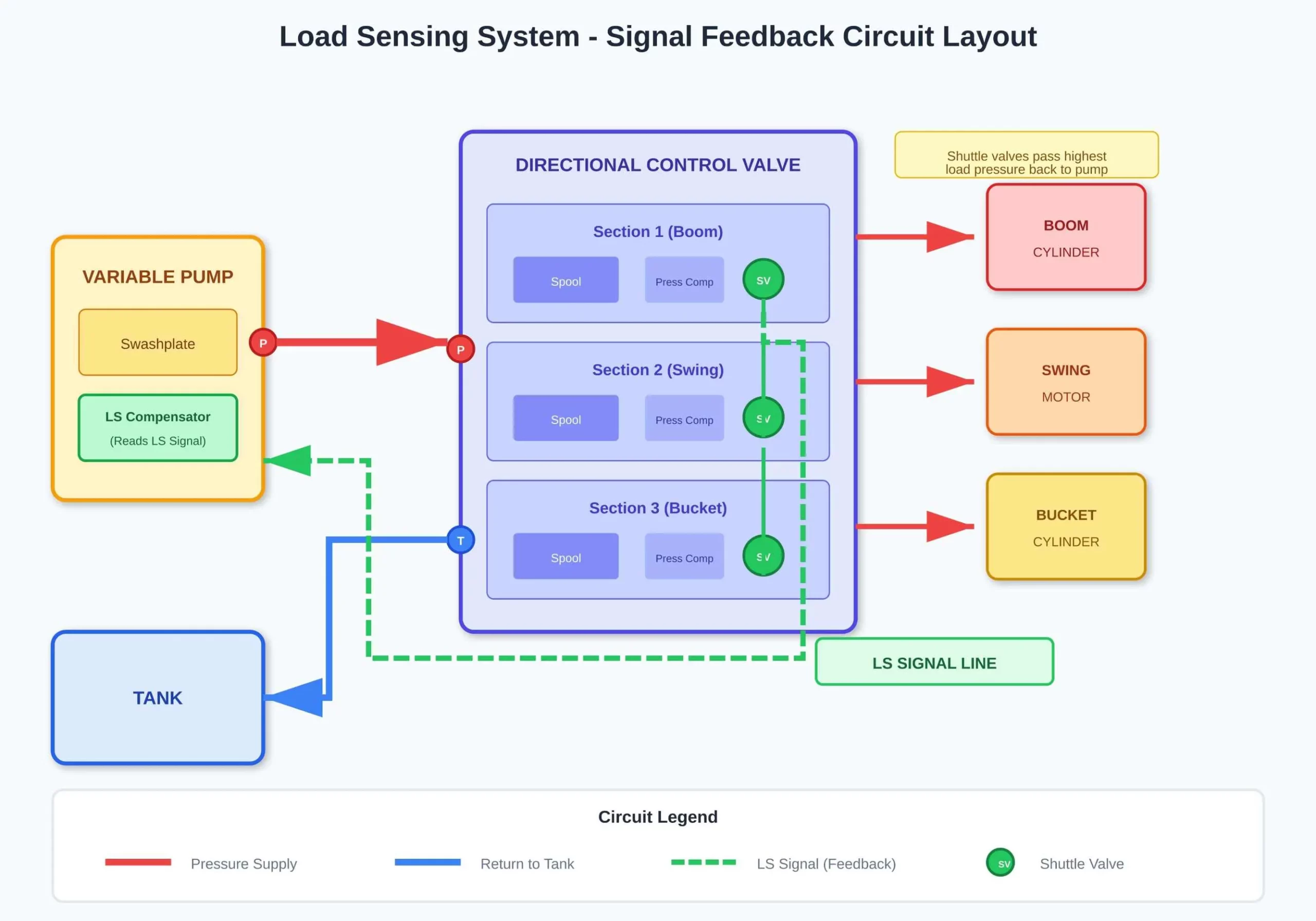

This diagram shows what makes LS systems different at the plumbing level. See that green LS signal line running from the valve back to the pump compensator? That’s the feedback circuit that doesn’t exist in open center systems. Inside the valve, shuttle valves in each section compare work port pressures and pass the highest one back through that line. The pump compensator reads that signal and maintains output pressure at LS + margin (typically 15-25 bar above the highest load). When you crack a spool, load pressure rises, the signal line tells the pump, and flow increases automatically. It’s elegant engineering—but those internal shuttle passages and signal orifices are exactly where contamination causes problems.

The fuel savings are real. Published research in the Energies journal showed LS systems hitting 45-55% hydraulic efficiency compared to 25-35% for open center. On a machine running 2,000 hours a year, that efficiency gap translates to serious money.

Metric | Open Center | Load Sensing | Difference |

Hydraulic efficiency | 25-35% | 45-55% | +15-25% |

Idle fuel consumption | Higher (continuous flow) | Lower (standby only) | 20-30% less at idle |

Multi-function performance | Functions compete for flow | Each function gets commanded flow | Significantly better |

Oil operating temperature | Higher | Lower | 10-15°C cooler typical |

The catch:

LS systems are picky about oil cleanliness. Those internal pilot passages and shuttle valves? They’re small. Metal particles that an open center valve would shrug off will jam an LS spool and kill the whole system.

We’ve tracked this across thousands of repairs: load sensing has the highest return rate of the three system types. Not because the engineering is bad—it’s actually excellent—but because operators and maintenance crews don’t always understand that ISO 18/16/13 cleanliness isn’t optional. It’s mandatory.

Common failure pattern: Customer calls saying their excavator “won’t do anything” or “stalls under load.” We pull the valve, find contamination in the pilot circuit, trace it back to a failed return filter that nobody replaced on schedule.

A word on operator feel:

Load sensing changes how the machine responds. Some operators love it—the consistent flow means the bucket moves at the same speed whether it’s empty or loaded with 3 tons of material. Experienced operators find they can work faster because the machine behavior is predictable.

Other operators, especially those trained on open center machines, find LS systems feel “disconnected” at first. The hydraulic feedback they’re used to isn’t there. Takes a few days to recalibrate muscle memory, but most adapt quickly once they understand what’s different.

Closed center sits between open center simplicity and load sensing sophistication.

When spools are neutral, flow to actuators is blocked completely. The pump maintains a low standby pressure but isn’t pushing volume through the system. Stroke a spool and a pressure signal tells the pump to wake up and deliver flow.

You get better efficiency than open center because you’re not constantly circulating oil. But you don’t get the precise load-independent flow control that makes LS systems so smooth during multi-function work.

Where closed center makes sense:

Port equipment and material handlers that need instant response from a dead stop. These machines often sit at idle for stretches, then need to move fast when a load appears. Closed center keeps the system primed and ready without burning fuel during wait time.

Let’s put efficiency claims into dollar terms.

Say you’re running a 25-ton excavator, 2,000 hours annually, diesel at $3.80/gallon. That machine burns roughly 4-5 gallons per hour under load.

System Type | Relative Fuel Use | Annual Fuel Cost (est.) | 5-Year Fuel Cost |

Open Center | Baseline | ~$38,000 | ~$190,000 |

Closed Center | 10-15% less | ~$32,300-34,200 | ~$161,500-171,000 |

Load Sensing | 15-25% less | ~$28,500-32,300 | ~$142,500-161,500 |

Estimates based on 4.5 gal/hr average consumption, 2,000 annual hours, $3.80/gal diesel. Your actual numbers will vary.

The EU ran a controlled study on load sensing excavators (Project ID: EE.-00546-85) and documented 12.1% fuel reduction versus conventional systems while simultaneously achieving 16% higher productivity. That’s not either/or—that’s both at once.

But here’s what the fuel savings charts don’t tell you: acquisition cost and maintenance complexity also factor into total ownership cost.

An LS system typically adds $12,000-18,000 to the purchase price of a mid-size excavator compared to open center. Variable displacement piston pumps cost more than gear pumps, require tighter filtration, and have higher rebuild costs when they eventually wear.

Run the payback math for your specific operation. High-utilization production machines? LS probably pays back in 18-24 months. A compact excavator that works 600 hours a year doing landscaping? Open center might be the smarter economic choice.

Forget the marketing specs for a minute. When we help customers choose valve configurations, we work through three questions:

Q — Flow capacity

What’s your peak flow requirement, and does the valve’s rated capacity handle it with margin to spare? An undersized valve creates pressure drop that eats efficiency and generates heat. We typically recommend 15-20% headroom above calculated peak demand.

P — Pressure rating

Continuous working pressure versus intermittent peaks. Relief valve settings. Cylinder force requirements. All of this has to align. Running a 35 MPa valve at 32 MPa continuous? That’s fine. Running it at 34.5 MPa continuous? You’re asking for shortened seal life and potential fatigue failures.

T — Technology fit

This one gets overlooked. Can your maintenance team actually service the system you’re buying?

If you’re sending machines to remote jobsites where the nearest hydraulic shop is 200 miles away and the local mechanic learned on gear pumps, maybe don’t spec the most sophisticated electrohydraulic LS system available. That fancy valve doesn’t help anyone when it’s down waiting for a specialist.

Different applications push different directions on valve selection.

Mining and heavy production (40+ ton machines)

Negative flow control (NFC) dominates here, and for good reason. NFC systems have inherently better damping characteristics for inertial loads like swing. When you’re rotating 80 tons of counterweight and boom, you want the hydraulics to absorb that momentum smoothly, not fight it. LS systems can get oscillatory under these conditions without careful tuning.

How NFC actually works: Instead of telling the pump how much flow to produce (like LS does), NFC tells the pump how much flow to reduce from maximum. There’s always a small bypass flow to tank that creates a control signal. Increase that bypass, and pump displacement drops. Block it off, and the pump goes to full stroke.

This creates naturally damped behavior. Heavy inertial loads cause pressure spikes that open internal relief paths, cushioning the system rather than fighting it. Operators describe NFC machines as feeling more “solid” or “planted” during aggressive swing-and-stop maneuvers.

The other factor: mining environments are brutal on equipment. Dust, vibration, temperature extremes. NFC tolerates abuse better than highly sensitive LS pilot circuits.

Port and material handling

Closed center with fast-response proportional valves. These applications demand instant breakaway torque and precise positioning. The crane picks up a container, swings it over the ship, and needs to stop exactly where the operator commands. Holding loads at position without drift is critical.

General construction (15-30 ton class)

This is the sweet spot for load sensing. Varied work cycles with lots of idle time between tasks. Frequent multi-function operation—digging while swinging, curling while booming up. The productivity and efficiency benefits stack up fastest in this middle weight class.

Compact and utility machines

Open center still holds territory here. Absolute fuel savings from LS are smaller on machines that only burn 1.5-2 gallons per hour anyway. The maintenance simplicity often outweighs efficiency gains for small contractors running compact equipment.

Harsh environments: A special note

Demolition sites, crushing operations, recycling yards—anywhere with extreme dust, debris, and vibration—deserve careful valve selection.

We generally advise against sophisticated electrohydraulic proportional valves in these conditions. Yes, they offer precise control. But those electrical connectors, solenoid coils, and position sensors live in an environment actively trying to destroy them. High temperature cycling fatigues wiring insulation. Dust infiltration shorts sensors. Vibration loosens connections.

A simpler hydraulic-pilot-operated valve survives where electronics fail. Less precision, sure. But 90% uptime beats 99% precision with 70% uptime.

Application | Recommended System | Primary Reason |

Mining excavators (40t+) | NFC or Electro-hydraulic LS | Stability with heavy inertial loads |

Port cranes/handlers | Closed center | Fast response, excellent load holding |

General excavation (15-30t) | Load sensing | Best efficiency/cost balance |

Compact excavators (<10t) | Open center | Simplicity, lower absolute savings |

Demolition/harsh environment | Open center or NFC | Contamination tolerance |

Sometimes we get calls from customers who bought machines with open center systems and want to upgrade to load sensing for the efficiency gains.

Short answer: Yes, but it’s expensive and complicated.

What’s actually involved:

You’re not just swapping valve blocks. Here’s the real scope of work:

Pump replacement: LS requires a variable displacement piston pump with pressure compensation and load sense control. Your gear pump won’t work, period. A quality replacement pump runs $8,000-15,000 depending on flow capacity.

Pilot circuit modifications: LS valves need dedicated pilot supply and return lines. Often means new hoses, fittings, and potentially a pilot filter assembly. Budget $1,500-3,000 for this work.

Signal plumbing: The load sense signal needs to route from each valve section back to the pump compensator through shuttle valves. That’s additional tubing, shuttle valve blocks, and potentially flow restrictors for signal damping. Another $2,000-4,000.

Wiring and controls: If going electrohydraulic, add harness modifications, controller programming, and potentially new joystick assemblies. $3,000-8,000 depending on complexity.

Calibration and testing: LS systems need the margin pressure set correctly, compensator tuned, and shuttle valve orifices adjusted to match the specific work ports on your machine. Get this wrong and you end up with a system that responds poorly or oscillates. Professional calibration runs $1,500-3,000 in labor.

Ballpark total for a retrofit on a 20-25 ton machine: $25,000-45,000 including labor, plus downtime.

Our honest take:

Unless your machine is relatively new with significant life remaining, retrofitting rarely makes economic sense. You’re better off spec’ing the right system on your next machine purchase and running the current one as-is until replacement time.

Contamination is the #1 killer across all system types.

We estimate 70% of valve problems trace back to the pump or filtration, not the valve itself. A filter element that ruptured six months ago sends debris through the whole circuit. By the time the valve starts acting up, the damage is done.

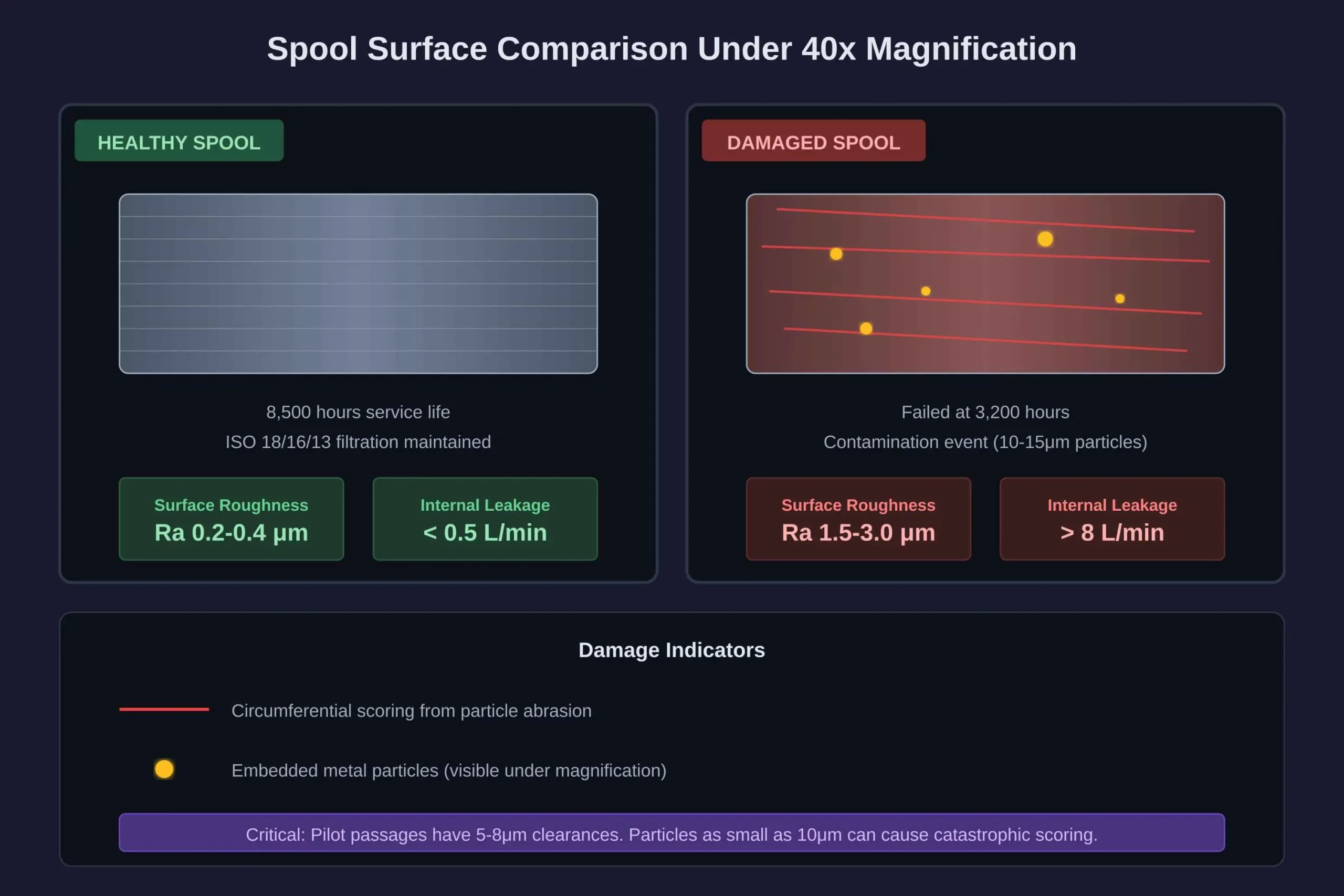

The image above shows two spool surfaces under 40x magnification. On the left, a spool from an LS valve that ran 8,500 hours with proper ISO 18/16/13 filtration—surface roughness still within spec at Ra 0.2-0.4 μm. On the right, a spool that failed at just 3,200 hours after a contamination event. Notice the deep circumferential scoring and embedded particles. That damage happened because metal debris as small as 10-15 microns got into pilot passages with 5-8 micron clearances. Once scoring starts, internal leakage climbs from under 0.5 L/min to over 8 L/min, and the spool begins sticking. By then, you’re looking at full valve replacement.

Typical symptom progression:

By stage 4, you’re looking at valve replacement plus potential pump damage plus contaminated cylinders. If someone had caught stage 1 and pulled an oil sample, a filter change and flush might have saved everything downstream.

System-specific failure patterns:

Open center: Spool wear from constant flow erosion. Internal leakage increases gradually over time, manifesting as slower speeds and higher operating temperatures. Usually gives long warning before catastrophic failure.

Load sensing: Pilot passage contamination causing spool sticking or pump control failure. Can go from “running fine” to “dead machine” quickly if debris blocks a critical orifice.

Closed center: Pressure compensator issues and accumulator pre-charge loss. The standby circuit tends to develop problems before the main circuit does.

What we recommend for any new valve installation:

Change all hydraulic oil. Replace all filters—suction, pressure, and return. If you’re not willing to do that, you’re gambling that whatever killed the old valve won’t kill the new one. It’s a bet you’ll usually lose.

Additional steps that extend valve life:

Maintenance Action | Frequency | Impact on Valve Life |

Oil sampling and analysis | Every 500 hours | Catches contamination early, prevents 60%+ of failures |

Return filter replacement | Every 500 hours or differential indicator | Primary contamination defense |

Pressure filter replacement | Every 1000 hours | Protects valve from pump wear debris |

Pilot filter inspection | Every 250 hours (LS systems) | Critical for load sensing reliability |

Breather element replacement | Every 500 hours | Prevents moisture and atmospheric contamination |

Full system flush | At every major component replacement | Eliminates legacy contamination |

High-quality valves from established manufacturers can deliver 8,000-10,000 operational hours under proper maintenance. That number drops to 3,000-5,000 hours in abrasive environments without disciplined filtration practices—a 50% reduction in service life just from skipping filter changes.

Danfoss has been pushing their Digital Displacement Pump technology hard, and the numbers are impressive. Their Dextreme system eliminates most throttling losses in the main control valve by precisely controlling pump output at the individual piston level.

Early implementations show 15% fuel reduction just from the pump swap. More advanced configurations claim 30-50% total energy savings.

The technology makes particular sense for electric and hybrid excavators where battery capacity is limited. Every efficiency gain extends operating time between charges.

That said, this is still emerging technology with limited field hours. For most operations buying equipment today, conventional LS systems remain the practical choice. But if you’re planning fleet purchases 3-5 years out, keep an eye on how digital displacement matures.

The Excavator Main Control Valve decision comes down to matching system capabilities to your actual operating conditions.

High-utilization production work with skilled operators and proper maintenance programs? Load sensing delivers returns that justify its complexity.

Harsh environments, remote locations, or smaller machines with lower annual hours? Open center’s simplicity and durability may serve you better.

Port operations and material handling? Closed center’s response characteristics fit the application.

Whatever you choose, remember that valve selection is just one piece. Proper filtration, scheduled oil sampling, and timely maintenance determine whether that valve gives you 3,000 hours or 10,000 hours of service.

For operations looking to source Excavator Main Control Valve assemblies or related hydraulic system components, working with a supplier who understands complete system integration—not just part numbers—makes the difference between a component swap and a lasting solution. POZOOM Hydraulic maintains 80%+ stock availability on major valve series and provides the technical support to help match components to specific machine requirements.

Note on Data and Claims: Efficiency percentages and fuel savings figures cited throughout this article derive from manufacturer testing data and published research. Actual results in specific applications may vary based on operating conditions, maintenance practices, operator technique, and equipment configuration. Cost estimates use representative values and should be recalculated using current fuel prices and local labor rates for specific purchasing decisions.

This article is intended for informational purposes for equipment managers, procurement professionals, and technical staff involved in excavator fleet management and hydraulic system specification. For specific component recommendations or system design assistance, consultation with qualified hydraulic engineering resources is recommended.