Menu

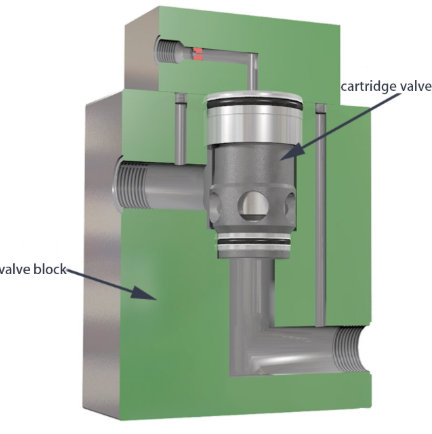

Cartridge valves are jokingly referred to as valves “without trousers” because their hydraulic functional parts have no external housing and must be installed in a block to work. At this time, the block housing the valve contains more than just oil passages, so it is called a manifold block.

The cartridge valve is completely separated from the pipe fittings, making replacement very convenient without the need to disassemble pipe connections.

Since the functional parts are installed inside the manifold body, multiple cartridge valves can be squeezed into one manifold block, making it very compact; the more complex the system, the more prominent this advantage becomes, making it the relatively most compact installation form.

Cartridge valves are mainly divided into two categories: slip-in type and screw-in type:

Commonly called cover plate cartridge valves, the valve body is pressed into the manifold block by a cover plate, invented in the 1970s.

Because the cover plate can be secured to the manifold block with multiple bolts, providing sufficient clamping force to fix the valve body, this form can withstand high pressure; it can only control the opening and closing of the flow path between two ports, so it is also called a two-way cartridge valve.

Cover plate cartridge valves can be used both as on-off valves (only controlling flow path opening and closing, also called logic valves) and as continuous valves (relief valves, throttle valves, etc.). When used as a relief valve, a valve with a 100mm diameter can control flow rates exceeding 7000L/min.

However, cover plate cartridge valves need to work with additional pilot control valves (“taking orders from other valves”), and are also jokingly called “brainless” valves; their functions are simple, structure is simple, and valve core is short, making them easy to make large.

The inlet and outlet passages of cover plate cartridge valves are A and B, and the control passage is X.

Cover plate cartridge valves with a 250mm diameter can control flow rates exceeding 100,000 L/min (0.5MPa pressure differential), meeting the needs of large hydraulic systems (such as anti-wave lifting on offshore drilling platforms).

When flow rates exceed 400~1000L/min, the manufacturing cost of cover plate type is lower than plate type, so plate-type valves with diameters above 25mm have been largely replaced.

A manifold block used in a 120MN free forging press uses cover plate cartridge valves with a 125mm diameter, with dimensions of 1540mm×1400mm×995mm.

There is also a cartridge valve manifold block used for a 2500t forging press.

The standardization of cover plate two-way cartridge valves has progressed smoothly: the installation connection dimension standard ISO 7368 (GB/T 2877), based on German DIN 24342 (1979), was completed in only three years, achieving interchangeability of cartridge valves from different manufacturers.

In addition, there are also three-way cover plate cartridge valves, but their application is far less than two-way types, so their visibility is relatively low.

Screw-in cartridge valves, i.e., threaded cartridge valves, have working principles essentially the same as other valves, differing only in structure: main components are arranged axially, screwed into the installation holes of manifold blocks/valve blocks through threads, and can independently complete hydraulic functions such as relief, electromagnetic directional control, and flow control.

Variations of threaded cartridge type:

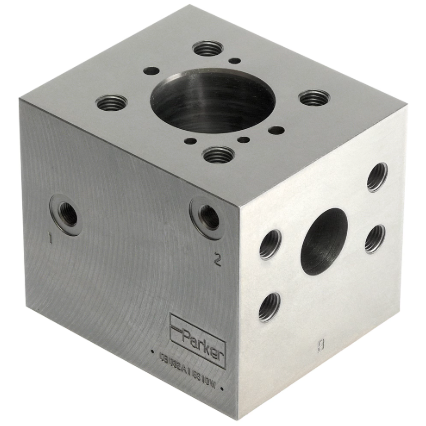

Manifold blocks/valve blocks only provide pressure-resistant housing for cartridge valves, with no other moving parts, simple installation hole processing (can be done with forming drill reamers); valves with different functions can share installation holes, reducing tools and facilitating replacement.

Inheriting the advantages of plate valve oil passage blocks: compact, small volume and light weight, reducing system initial costs; less leakage, small pressure loss, less heat generation, high reliability, reducing operating costs.

Specialized manufacturing of manifold blocks is mature: specialized factories can complete design and quotation within a few days, and complete material preparation, manufacturing, assembly and testing in 3~4 weeks; the “turnkey” model reduces the effort and expenses of the main equipment manufacturer, and is the preferred choice for current hydraulic system design.

The author does not agree with the statement that “cover plate type is the fourth generation and threaded cartridge type is the fifth generation of hydraulic valves”: both have their own applicable ranges and cannot replace each other; moreover, threaded cartridge type appeared earlier than cover plate type, and international standards were also being developed simultaneously.

The author emphasizes: ① Classification is incomplete; in reality, there are varieties that fall between the two categories (such products often have vitality because they absorb advantages and discard weaknesses); ② Classification is the starting point of learning, not the end point, and classification should not be rigidly used to hinder innovation.