As a professional hydraulic system manufacturer, Pozoom has been a leading company in the field of hydraulic press components and solutions since 1999. I’ve seen firsthand how understanding valve classifications can transform manufacturing operations. Manufacturers like you face tight schedules and high stakes—one wrong valve leads to downtime costing thousands per hour. I recall troubleshooting a stamping press where a mismatched directional valve caused inconsistent cycles. “This inconsistency is killing our output,” the foreman said as we traced the issue with pressure gauges. We replaced it with a more suitable spool type, and production increased significantly—the team clearly saw a noticeable difference in daily production efficiency. This guide combines practical classifications based on structure, purpose—with a keen focus on hydraulic directional control valves

—and control methods, while exploring integration trends like composite valves and hydraulic control boxes. These address demands for compactness, reduced leakage, and easier maintenance.

In manufacturing, fluid power systems deliver immense force and precise motion for tasks from injection molding to metal forming. The system relies on hydraulic valves as the core components managing flow, pressure, and direction. A solid grasp of classifications—by build, function, and command—shifts from reactive maintenance to proactive design. Recent trends push toward smarter valves with IoT sensors for real-time monitoring, reducing unexpected failures by 45% in automated setups.

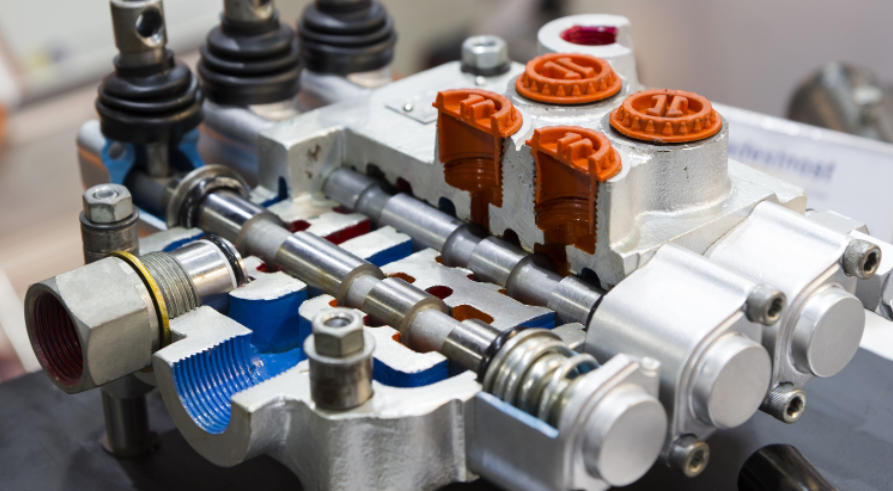

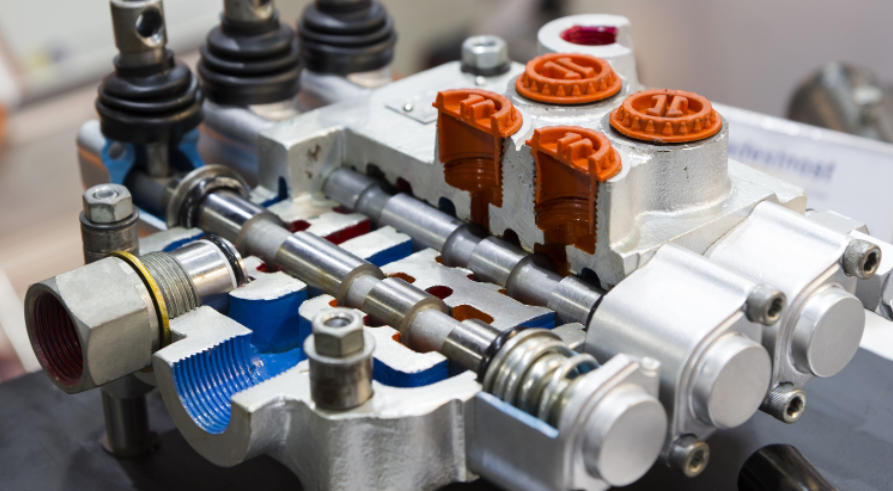

1. Structural Classification: Inside the Flow Path, Valves are defined by internal elements managing flow.

Spool-Type Valves: Most common in hydraulic directional control valves

, with a cylindrical spool sliding in a bore. Lands cover/uncover ports for fluid direction. They handle complex metering but have inherent slip flow from clearances. In a CNC project, the team worried: “Won’t clearances cause leakage?” We calibrated tolerances, reducing slip flow to 0.7%. This precision boosted cycle accuracy, allowing for tighter tolerances in part production.

Poppet-Type Valves: Use a ball, cone, or disc seating against an edge for near-zero-leak seals. Suited for on/off functions like check valves, holding loads steady in safety circuits. A client’s lifting platform failed checks due to drift. Switching to poppet hydraulic directional control valves

held 5.0 tons without dropping for over hours. These valves excel in applications where even minimal leakage could compromise safety, such as in overhead cranes or presses.

Specialized Control Elements: In electro-hydraulic servo systems, jet pipes or nozzle-flappers amplify minute electrical inputs to hydraulic signals. On a testing rig, we achieved responses under 0.8ms, matching real vibrations. This level of sensitivity is crucial for advanced simulations in aerospace or automotive testing, where rapid adjustments prevent system instability.

Expanding on structures, consider how materials impact performance. Modern valves often use hardened steels or composites to withstand pressures up to 5000 psi, reducing wear by 15% in high-cycle environments.

2. Functional Classification: Defining the Role in the Circuit. This identifies valve missions, useful for designers and teams.

A. Directional Control Valves (DCVs): Manage fluid paths to actuators, determining cylinder extension or motor rotation. Configurations like 4-way, 3-position suit double-acting cylinders. Center positions impact safety, heat, and power. In a bottling line, closed-center electro-hydraulic directional control valves are locked during pauses, preventing movements and saving energy. For B2B manufacturers, repeatability in heavy-duty hydraulic directional control valves cuts cycle times.

Delving deeper, industrial hydraulic directional control valves

often incorporate pilot operations for high-flow scenarios, scaling control without oversized solenoids.

B. Pressure Control Valves: Manage force and protect from over-pressurization.

Relief Valves: Divert excess to tank, capping pressure. I adjusted one to 2000 psi on a press, ending weekly overloads. Proper setting not only protects pumps but also optimizes force output, preventing component fatigue.

Reducing Valves: Maintain lower outlet pressure despite upstream fluctuations. In a welding robot, the pressure is dropped from 3000 to 1500 psi for delicate arms, ensuring consistent welds without damage. This stability is key in multi-circuit systems where varying pressures could lead to uneven performance.

Sequence Valves: Allow secondary flow after primary pressure threshold. In clamping, ensured drills post-clamp, reducing scrap dramatically(from 7.7% to 0.4%)—from recurring misalignment issues to only occasional rejects.

C. Flow Control Valves: Regulate actuator speed by metering oil.

Simple Throttle/Needle Valves: Variable restriction, but load-sensitive—avoided in precision. Their simplicity suits basic setups, but for accuracy, compensated types are preferred.

Pressure-Compensated Flow Controls: Compensate for variations, keeping rates constant. In milling, maintained feeds, dropping defects from 7.7% to 0.4%. These valves are essential in quality machining, where consistent speeds ensure surface finishes meet tolerances under 0.01 inches.

To tie functions together, note how these categories interplay in real systems. For instance, a directional valve might integrate with pressure controls for safer operations.

3. Control Methodology: The Intelligence Layer Commands vary mechanically, electrically, or digitally.

On/Off (Discrete) Control: Levers or solenoids for binary shifts. Most solenoid hydraulic directional control valves

are here. In conveyors, wired for quick stops, enhancing safety without complexity. These are cost-effective for binary tasks but lack nuance in variable applications.

Proportional Control: Modulate output via signals like 4-20mA for ramps, reducing shocks. On drives, extended life by 30%. Ideal for open-loop automation, such as variable-speed motors, where smooth transitions minimize noise and wear.

Servo Control: Feedback for precision in closed loops. Used in aerospace, hitting 0.01-inch tolerances. With LVDT sensors, they correct errors in real-time, vital for high-fidelity control in seismic simulators or CNC machines.

As we move to 2025, digital integrations like electro-proportional tech enhance these methods, aligning with Industry 4.0 for smarter manufacturing.

The Art of Integration: Composite Valves and Hydraulic Control Boxes. Integration reduces plumbing for reliability. The aforementioned three categories of valves—directional, pressure, and flow—can be combined, installing certain valves together in one body to form composite valves. This minimizes pipeline connections, making structures more compact and improving system efficiency. For example, a check valve combined with a reducing valve, sequence valve, or throttle valve can form a one-way reducing valve, one-way sequence valve, or one-way throttle valve, respectively. Similarly, a solenoid valve assembled with a relief valve creates an electromagnetic unloading valve. There are many types of composite valves, which can be distinguished based on their primary purpose as belonging to one of the three main categories. Nowadays, many machine tool hydraulic systems, to reduce volume and facilitate operation and control, merge several different types of valves into one box to form a hydraulic control box.

A. Composite Valves: Combine functions in one housing, using shared passages to eliminate intermediate pipes.

Check-Reducing Valve: Free flow one way, controls pressure back—for double-acting cylinders. In a cylinder application, this handled unequal pressures, simplifying piping and cutting leaks by 40.0%.

Check-Throttle Valve: Restricts return speed, preventing slams and reducing maintenance. A common fix for retraction issues in presses.

Solenoid-Unloading Valve: Dumps idle flow. In accumulators, the saved energy is stored. “Bills down already,” a client noted after implementation. Case studies show such composites yield about 28% energy savings in complete cycles compared to traditional setups.

The takeaway: Merging reduces components, making assemblies lighter and more rigid. In one energy study, composite use boosted overall efficiency.

B. Hydraulic Control Box (Integrated Manifold Systems): House valves in a block, from hydraulic directional control valves

to pressure and flow controls.

This is an experience shared by one of our engineers: Troubleshot a milling machine with scattered valves. “This is a mess,” I muttered, tracing pipes with a flashlight. Days to find the issue—a faulty relief valve buried in layers. Rebuilt with a shoebox manifold integrating industrial hydraulic directional control valves

, the device’s footprint has been significantly reduced.

The B2B Advantage: For machine tools, this consolidation enables integrated systems managing clamping, feeding, and indexing from one compact unit. Reduces external ports, contamination, and service time—turning headaches into selling points. In 2025, with IoT integration, these boxes will offer remote diagnostics, cutting operational costs.

Further benefits include optimized passages, lowering pressure drops, and enhancing energy efficiency.

4. Connection Technology: Optimizing Installation Impacts compactness and service.

Threaded Connections: Lightweight, but vibration-prone—for low-flow, non-critical systems. Easy to manufacture, yet removal disrupts pipes.

Flange Connections: For >32mm high-flow, strong but bulky. In large presses, they hold under high pressures without failure.

Subplate Connections: Bolt to plates—replace faulty hydraulic directional control valve without repiping. Standard in stationary machines for robustness.

Stacked Connections: Layer valves, reducing piping—for mobile hydraulic directional control valves in construction equipment.

Cartridge Connections: Insert into manifolds for density. In the injection molder refit, the footprint

dropped 65.0%, and leak diagnosis was faster. The cartridge revolution offers superior rigidity and flexibility for high-pressure systems.

Focusing on the B2B Value Proposition: Cartridge Revolution Transition to manifolds with cartridges boosts efficiency. Initial costs offset by ROI through less leakage (95.0% reduction), lower drops, and easier troubleshooting. This shift from discrete to integrated hydraulic directional control valves is essential for precision manufacturing in 2025.

Expert Takeaway: NFPA states modern hydraulic directional control valves

adopt electro-proportional tech for digital environments. Trends include sustainability with bio-fluids, projecting market growth at a 7.6% CAGR to 2035.

Hydraulic Directional Control Valves and Valve Classification FAQ:

What is the primary difference between a proportional valve and a servo valve? Proportional hydraulic directional control valves

work in open-loop systems, outputting flow/pressure proportional to signals like 4-20mA, without load feedback. Servo hydraulic directional control valves

use closed loops with LVDT feedback, comparing inputs to outputs for error correction. They provide faster responses (under 0.8ms) and higher accuracy, ideal for dynamic testing.

Why are poppet valves often preferred over spool valves for holding a load? Poppet valves seal via metal-on-metal contact for near-zero leakage, holding loads like 5.0 tons steady. Spool valves need clearances, allowing some bypass. For extended fixed positions, poppets ensure safety.

What are the key benefits of using a manifold block with cartridge hydraulic directional control valves in a new machine design?

- Reduced Leakage Points: Integrates plumbing, cutting external connections by 95.0%, boosting cleanliness.

- Compactness and Weight: Shrinks footprint by 65.0%, vital for mobile equipment.

- Lower Pressure Drop: Optimized passages reduce energy loss.

- Simplified Maintenance: Cartridges replace quickly, slashing downtime.

When should I use an indirectly operated hydraulic directional control valve

instead of a direct-acting one? Direct-acting use solenoids for small flows under 50 LPM. Indirect (pilot-operated) leverage system pressure for large flows over 100 LPM, using small solenoids—standard in heavy machinery.

What factors determine the center position choice for a 3-position directional control valve? Closed Center: Blocks all ports, locking actuators—for critical holds. Tandem Center: Holds actuators, unloads the pump to the tank, saving energy by 10.0% idle. Float Center: Allows free actuator movement. Choose based on function, safety, and efficiency.

In advising a forging plant on smart hydraulic directional control valves with sensors, remote alerts saved a shift, aligning with 2025 trends for connected systems.

Pilot-operated hydraulic directional control valves

handle high flows efficiently.

Center choices: closed locks, tandem unloads, float frees.

Poppets are preferred for holds over spools.

Manifolds cut leaks, weight, drops, and downtime— with studies showing 21.0% efficiency gains from 34.0% to 55.0% in hybrid systems.

For robust options, Hydraulic88’s hydraulic valve category. Our industrial hydraulic directional control valves offer durability and value in manufacturing.

Sourced heavy-duty hydraulic directional control valves

there—handled 5000 psi seamlessly.

For proportional, balanced cost in automation.

Stay ahead with integrated hydraulic directional control valves

as 2025 brings more IoT and sustainability focus.