Menu

Directional control valves reduce energy consumption through load-sensing technology, pressure compensation, and low-power solenoids that match system demand to actual requirements. Modern systems achieve energy savings between 20% and 50% by eliminating unnecessary pressure drops and minimizing power waste during idle periods.

Load-sensing systems represent the most effective energy-saving approach for hydraulic directional control valves. Rather than maintaining constant maximum pressure, these systems detect actual load requirements and adjust pump output accordingly.

The core mechanism involves a feedback loop between the valve and pump. The directional valve’s load-signal gallery connects to work ports through shuttle valves, sensing the highest load pressure across all actuators. This signal feeds back to the pump controller, which adjusts displacement to maintain a modest pressure differential—typically 10 to 30 bar—above load requirements.

Research on dual-variable load-sensing systems demonstrates average energy savings of 20%, with peak efficiency reaching 50% under optimal conditions. The system maintains pressure fluctuations within 5% while substantially reducing parasitic losses.

Traditional fixed-displacement systems waste energy when full flow isn’t required. The excess fluid passes over relief valves, converting unused hydraulic power to heat. Similarly, pressure-compensated pumps without load sensing maintain maximum system pressure regardless of actual load demands, creating unnecessary pressure drops across metering orifices.

Load-sensing control eliminates both inefficiencies. When cylinders operate at partial capacity or actuators remain idle, the pump reduces flow and pressure to just above what’s needed. During standby periods with all spools centered, the system drops to minimum standby pressure—essentially the load-sensing controller’s delta-p setting—rather than maintaining full relief valve pressure.

The technology also improves actuator control. By maintaining constant pressure drop across the directional control valve spool, load sensing keeps flow rates consistent regardless of load variations. A winch lifting increasing weight, for example, maintains steady speed because the pump automatically compensates for rising load pressure.

Pressure-compensated direction valves incorporate individual compensators at each valve section inlet. These compensators work alongside spool-selected orifices to maintain constant flow rates despite pressure variations from simultaneous function operation.

The compensator mechanism uses a differential pressure regulator—typically a spring-loaded spool or poppet—that automatically adjusts its opening. When multiple actuators operate simultaneously, load pressures vary across different circuits. The compensator at each section responds to these variations, throttling flow to maintain a fixed pressure drop across the main spool.

This load-independent flow distribution proves particularly valuable in mobile equipment where operators frequently run multiple functions together. Excavators extending booms while rotating, or loaders lifting while traveling, benefit from predictable actuator speeds regardless of individual load differences.

Three-way pressure-compensated flow control valves offer additional efficiency advantages over two-way designs. In three-way configurations, excess flow returns to tank through the valve rather than over the pump’s relief valve. System pressure remains equal to actuator pressure plus spring pressure, avoiding the energy waste of maintaining full pump pressure when only partial flow is needed.

Manufacturers report that modern pressure-compensated valves equipped with digital controls improve energy efficiency by up to 30% compared to non-compensated alternatives. The precision of flow metering reduces component wear and extends fluid life by minimizing heat generation.

Solenoid power consumption directly impacts energy costs in automated hydraulic systems. Modern low-wattage solenoid designs reduce electrical draw from traditional 15-20W coils to as little as 0.55W while maintaining reliable actuation force.

Duplomatic’s DS3L series demonstrates this evolution, operating at just 8W with 24V DC power supply. The design uses wider internal flow paths to minimize pressure drops while the low-energy solenoid provides sufficient force for positive spool shifting.

ASCO’s ultra-low-power valves consume only 0.55W, making them viable for battery and solar-powered remote installations. These valves employ tighter tolerances, optimized magnetic circuits, and enhanced mechanical efficiency to achieve the same switching force as higher-power alternatives.

The energy savings compound across large installations. A facility operating 500 continuously-energized solenoids sees dramatic differences: traditional 9.5W coils consume 4,750W total, while 1.8W low-power alternatives draw only 900W—an 81% reduction. At typical industrial electricity rates, this translates to thousands of dollars in annual savings.

Beyond direct energy costs, low-power solenoids generate significantly less heat during operation. This reduces thermal stress on valve components and surrounding equipment, extending service life and reducing cooling requirements in enclosed control panels. The lower heat generation also improves reliability in high-temperature environments where thermal buildup might otherwise cause coil failure.

Pilot-operated configurations amplify these benefits. Instead of the solenoid directly actuating the main spool, it controls air or hydraulic pressure that provides the actuation force. This indirect method dramatically reduces required solenoid power since the bulk of actuating force comes from system pressure rather than electromagnetic force.

The neutral position configuration of three-position directional valves significantly impacts energy consumption during idle periods. Four primary center types offer distinct efficiency characteristics.

Closed-center valves block all ports in neutral, maintaining system pressure without fluid circulation. This design proves most energy-efficient for systems using variable-displacement pumps, as the pump can reduce flow to near-zero during idle periods while maintaining pressure for rapid response.

Open-center configurations return fluid to reservoir when neutral. While less efficient for maintaining pressure, they suit fixed-displacement pump systems where continuous flow is inherent. The open center prevents pressure buildup and reduces heat generation during extended idle periods.

Tandem-center designs block work ports while allowing pump flow to return to reservoir. This provides a compromise between closed and open centers—maintaining work port isolation for actuator positioning while preventing unnecessary pressure buildup. Tandem centers work well in mobile equipment requiring both energy conservation and quick response times.

Regenerative-center valves allow fluid flow from outlet back to inlet in neutral position, increasing actuator speed and reducing energy consumption during certain operations. The regenerative path can nearly double cylinder extension speed by combining pump flow with return flow, effectively providing more work from the same pump output.

Proper center selection based on application requirements and pump type can reduce idle power consumption by 40-60% compared to mismatched configurations.

Modern sectional hydraulic directional control valves employ modular designs that minimize internal pressure losses while maximizing flow efficiency. The stackable construction allows customization of valve groups without compromising hydraulic performance.

Wide internal flow passages reduce turbulence and friction losses as fluid moves through multiple valve sections. Parker’s VPL series and Danfoss’s PVG valves exemplify this approach, maintaining low pressure drops even at high flow rates—critical for preserving system efficiency.

The sectional design also enables selective sizing. Rather than using a single large valve for all functions, engineers can size individual sections to match specific actuator requirements. A cylinder needing 30 GPM operates through a section rated for that flow, while a smaller 10 GPM motor uses an appropriately sized section. This prevents the energy waste of oversized valve ports where excess clearance creates unnecessary pressure drops.

Integration of function manifolds within the valve stack further reduces pressure losses by eliminating external piping between components. Each connection point in a hydraulic system introduces potential for leakage, pressure drop, and turbulence. Consolidating functions into a single valve assembly minimizes these losses.

HYDAC’s load-sensing control blocks achieve high performance density through compact valve design that saves installation space and reduces resource consumption. The integrated approach allows up to ten functions to operate independently while maintaining energy-efficient load compensation across all sections.

Electrohydraulic control systems integrate electronic feedback and programmable logic with hydraulic directional valves to optimize energy usage dynamically. These systems adjust valve actuation based on real-time load conditions, operator commands, and efficiency algorithms.

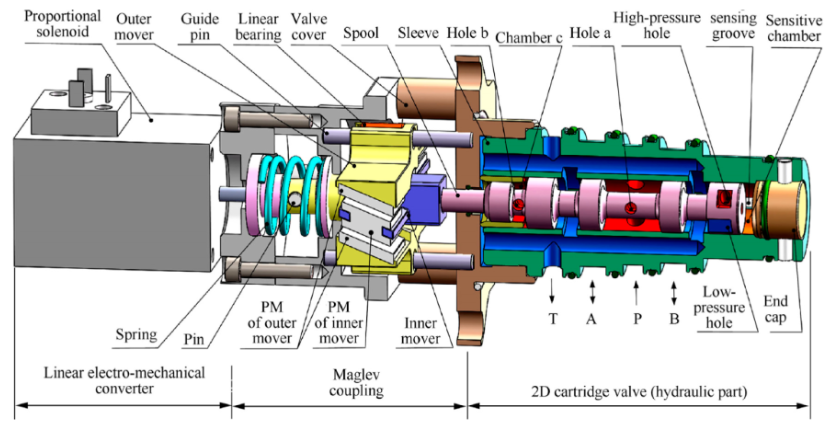

Proportional valves with electronic spool position feedback enable variable flow control more precise than traditional mechanical pilot systems. Rather than simple on-off switching, proportional solenoids modulate valve position continuously, providing only the flow rate required for specific tasks. This eliminates the energy waste of excess flow passing over pressure relief valves.

CAN bus communication allows centralized monitoring and control of multiple valve sections. The control unit receives data from pressure sensors, flow meters, and position transducers throughout the hydraulic system, making intelligent decisions about pump displacement, valve actuation timing, and load distribution.

Research on electronic flow matching (EFM) strategies shows impressive results. By calculating required pump displacement and valve orifice areas based on operator commands, EFM systems directly control pumps to supply needed flow and distribute it efficiently through valve sections. One hybrid automotive application increased hydraulic system efficiency from 34% to 55%, yielding an 11.8% improvement in overall fuel efficiency.

Smart valve technology equipped with sensors and intelligent control systems can autonomously adjust flow and pressure based on real-time operational feedback. This capability supports predictive maintenance by detecting performance degradation before failures occur, preventing energy-wasting system inefficiencies from developing unnoticed.

Internal leakage past directional control valve spools represents a continuous energy drain that worsens as components wear. Modern valve designs incorporate advanced sealing technologies and tighter manufacturing tolerances to minimize this parasitic loss.

Seal wear compensation features automatically adjust for gradual wear, maintaining sealing effectiveness throughout the valve’s service life. Parker’s K220LS valves employ patented seal wear compensation technology that preserves reliable sealing under both pressure and vacuum conditions, preventing leakage that would otherwise waste energy.

The energy impact of leakage compounds in pressure-compensated systems. Because these systems maintain elevated pressure most of the time, any leakage represents high-pressure fluid bypassing productive work. Even small clearances—0.05mm between spool and bore—can pass significant flow at typical system pressures, generating heat and requiring additional pump power to maintain pressure.

Manufacturing precision plays a crucial role. Computer-controlled machining achieves surface finishes and dimensional tolerances that reduce clearance-based leakage by 60-70% compared to conventional manufacturing. The investment in precision manufacturing pays dividends through reduced energy consumption over the valve’s operational life.

Wet-type solenoid designs further reduce noise and wear. The solenoid armature operates immersed in hydraulic fluid, providing lubrication that minimizes friction and prevents seal degradation. This design choice extends component life while maintaining low internal leakage rates.

Energy savings from directional control valves compound when integrated with complementary hydraulic components. The system-level approach addresses energy use holistically rather than optimizing individual components in isolation.

Variable-displacement pumps paired with load-sensing directional valves create synergistic efficiency gains. The pump automatically adjusts output based on valve-sensed load demands, while the valve’s pressure compensation ensures precise flow distribution. Together, they eliminate most parasitic losses that plague fixed-displacement systems.

Accumulator integration smooths pressure spikes and reduces cycle-induced stress on components. A small accumulator at the pump outlet dampens rapid compensator shifts in pressure-compensated systems, reducing power spikes and extending component life. The accumulator can also provide short-duration high flow without increasing pump size, saving energy during lower-demand periods.

Proper filtration protects valve components from wear that increases internal leakage. While high-grade filtration requires modest energy input for the filter circuit, this investment prevents the larger energy losses from degraded valve sealing and contamination-induced sticking.

Fluid temperature management affects overall system efficiency. Cooler operation reduces fluid viscosity losses and improves sealing effectiveness, but cooling systems consume energy. Load-sensing directional control valves generate less waste heat than traditional systems, often eliminating the need for supplemental cooling and its associated energy consumption.

Hydraulic system efficiency improves dramatically when engineers consider the entire circuit rather than individual components. Research shows that properly configured load-sensing directional valves with matched pumps, appropriate sizing, and quality filtration can achieve system efficiencies exceeding 80%—more than double the efficiency of poorly designed systems using basic components.

Load-sensing systems typically achieve 20-30% energy savings compared to fixed-displacement or simple pressure-compensated systems, with peak savings reaching 50% under optimal conditions. The actual savings depend on duty cycle, load variation, and how much time the system spends in partial-load or idle conditions. Systems with frequent idle periods or highly variable loads see the greatest benefit.

Upstream compensation places the pressure compensator before the directional valve spool, maintaining constant pressure differential across the spool metering edge. Downstream compensation positions compensators after the spool, sensing load pressure directly and providing superior flow sharing when operating multiple functions simultaneously. Downstream compensation generally offers better energy efficiency and control precision.

Modern low-power solenoid designs maintain reliability and response characteristics equal to or better than traditional high-power coils. Advances in magnetic circuit design, materials, and manufacturing tolerances enable the same switching force with less electrical input. In fact, reduced heat generation often improves reliability by minimizing thermal stress on coil windings and adjacent components.

Many systems can be upgraded, though the extent of modification varies. Replacing directional valves with load-sensing or pressure-compensated alternatives typically requires compatible pump controls and appropriate plumbing for load-signal feedback. The best retrofit candidates are systems with variable-displacement pumps and adequate space for modular valve installations. Simple solenoid coil upgrades to low-power versions are usually straightforward.

The energy-saving potential of modern directional control valves extends beyond simple component efficiency. When load-sensing technology, pressure compensation, and low-power actuation work together within properly designed hydraulic systems, the cumulative effect can reduce operational costs by 25-40% while improving reliability and performance. Each technology addresses different aspects of energy waste—load sensing eliminates unnecessary pressure, compensation prevents flow imbalances, and low-power solenoids reduce electrical consumption. The key lies in matching valve characteristics to application requirements rather than applying a one-size-fits-all solution.

Engineers selecting hydraulic directional control valves should evaluate energy consumption across the system’s full operating range. A valve configuration that performs efficiently at maximum load might waste substantial energy during partial-load operation that represents 70% of actual runtime. Analyzing real-world duty cycles reveals optimization opportunities that pure specification-sheet comparisons miss.

Related valve technologies: Proportional flow control, servo valves, hydraulic cartridge valves, pressure relief valve systems, flow divider applications