Menu

Hydraulic technology has a history of more than 200 years of development. To work with hydraulics, hydraulic valves are needed. Therefore, the research and development of hydraulic valves has also been going on for more than 200 years. To meet the needs of host machines and hydraulic systems, thousands upon thousands of diverse hydraulic valves have emerged. However, in terms of function, almost all hydraulic valves can be classified into the following four major categories of twelve types, or are transformed from these types, or are composed of combinations of these types:

Including one-way valves, pilot-operated check valves, and shuttle valves, the flow passage resistance is either very small (closed) or very large, to restrict the direction of fluid flow.

The flow passage is usually changed by external operation, with resistance being either very small or very large.

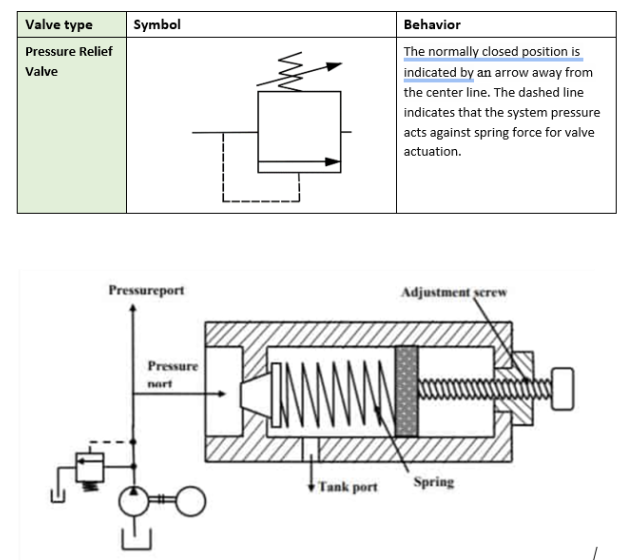

Including relief valves, pressure reducing valves, and sequence valves: the opening and closing of the flow passage is controlled by the pressure at the valve inlet or outlet.

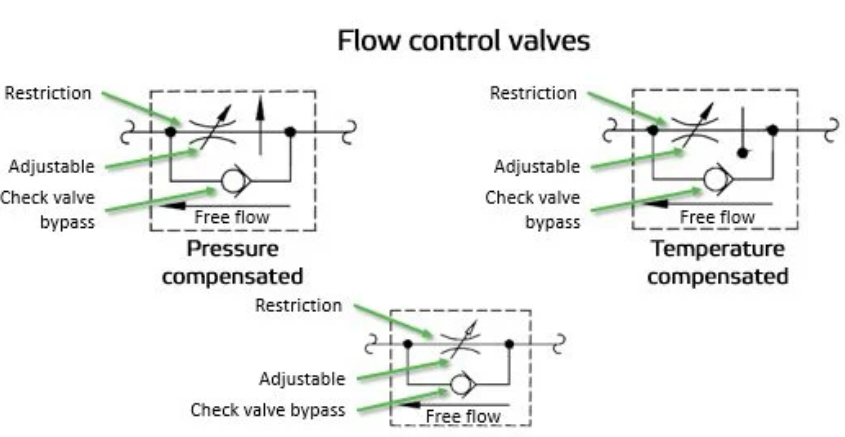

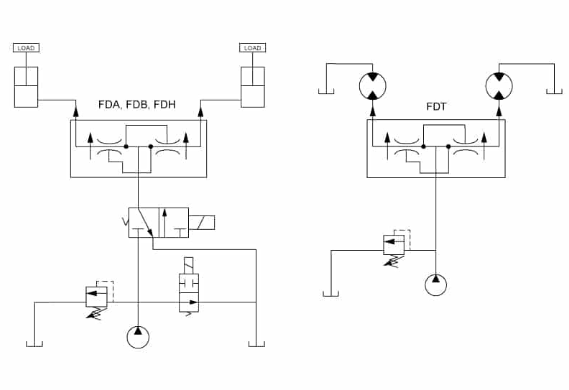

Among these, throttle valves are externally operated, while two-way flow control valves and three-way flow control valves can automatically adjust according to pressure difference using constant pressure difference elements, and flow divider-combiner valves can adjust the resistance of their own flow passage according to the flow rate of corresponding flow passages. Their essence is all to restrict flow rate.

Here, the term “restrict” is specifically used instead of “control,” because in general understanding, “control” means being able to make the controlled object follow commands to go up and down. But hydraulic valves are passive components that can only consume, cannot create something from nothing, can only go down but not up, cannot turn low into high, therefore, using “restrict” is more precise!

Pressure valves and flow control valves: the opening must continuously adjust with flow rate or pressure; throttle valves must also continuously change with external adjustment, with resistance changing continuously, therefore, they can be classified as continuous valves.

As mentioned before, all hydraulic valves complete their tasks by moving the valve spool and changing the opening (flow passage). Therefore, what kind of control force pushes the valve spool determines the function of the valve. How the valve spool moves under the combined action of control force and resistance determines the performance of the valve. This is the key to mastering all valves.

On the hydraulic valve body, the ports in contact with the oil can be divided into passage ports and control ports.

Include understanding volumetric speed control principles and proper valve classification.