Menu

Hydraulic fluid quality directly determines system reliability, with 75-90% of all hydraulic failures traced to contaminated or degraded fluid. The viscosity, cleanliness, and additive package of your hydraulic oil affects pump efficiency, component lifespan, and operating costs.

System failures caused by low-quality hydraulic fluids create a cascade of expensive problems. Contaminated fluid accelerates wear on precision components like pumps and valves, where clearances measure in microns. When fluid quality drops, internal leakage increases, reducing volumetric efficiency and forcing pumps to work harder. This extra workload generates excess heat, which further degrades the fluid—creating a destructive feedback loop.

Research shows that for every 10 degrees above normal operating temperature, hydraulic fluid life cuts in half. Low-quality fluids with poor thermal stability break down faster at elevated temperatures, forming sludge and varnish deposits that clog filters and restrict flow. These deposits accumulate on valve spools and orifices, causing erratic operation and eventual component seizure.

The financial impact extends beyond repair costs. Unexpected downtime in industries like manufacturing or construction can cost thousands per hour. Mobile equipment operators face additional fuel consumption penalties—high-quality fluids with optimized viscosity index have demonstrated 5-10% energy savings compared to standard monogrades. For a single hydraulic pump, this translates to hundreds of dollars in annual savings.

Viscosity governs how hydraulic fluid performs under varying temperature and pressure conditions. Most hydraulic systems require operating viscosity between 16-40 centistokes for optimal efficiency. When viscosity falls outside this range, problems multiply quickly.

Fluid that’s too thin (low viscosity) cannot maintain adequate lubrication films between moving parts. Metal-to-metal contact occurs, causing accelerated wear on pump bearings, pistons, and valve surfaces. The thinner fluid also increases internal leakage past seals and clearances, reducing system pressure and response time. Operators notice sluggish cylinder movement and weak force output.

Conversely, excessively thick fluid (high viscosity) creates high flow resistance. Pumps must work harder to move the viscous fluid, wasting energy as heat. Cold startups become particularly problematic—thick fluid may not reach the pump quickly enough, causing cavitation damage as the pump tries to draw fluid through restricted lines. Air bubbles form and implode violently against metal surfaces, pitting and eroding components.

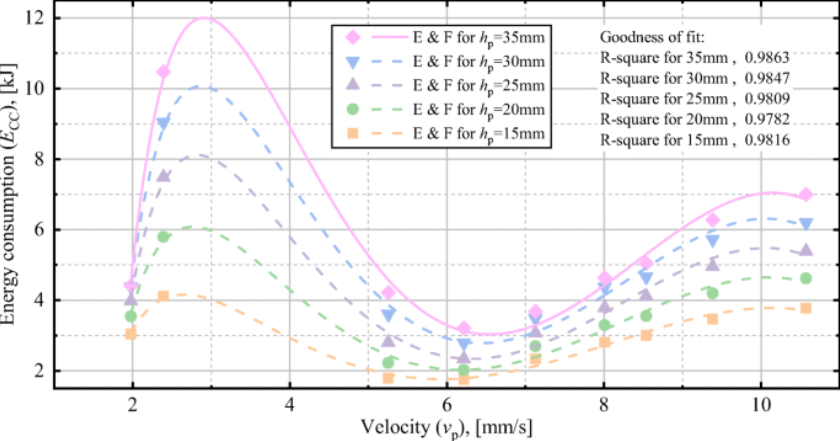

Temperature dramatically affects viscosity. Hydraulic systems operating outdoors face ambient temperatures from below freezing to over 150°F. Standard monograde fluids thin significantly when hot and thicken when cold, pushing systems outside optimal viscosity ranges. High viscosity index (VI) multigrade fluids maintain more consistent viscosity across temperature swings, though they cost more upfront. Field tests on industrial hydraulic presses showed multigrade fluids delivering efficiency gains of 4-11% compared to conventional monogrades.

Particulate contamination accounts for the majority of hydraulic component damage. Sand, metal particles, and degraded seal material circulate through systems, acting as abrasives that score precision-machined surfaces. Even particles as small as 5 microns—far below what the unaided eye can see—cause harm in modern hydraulic systems where pump clearances measure 1-3 microns.

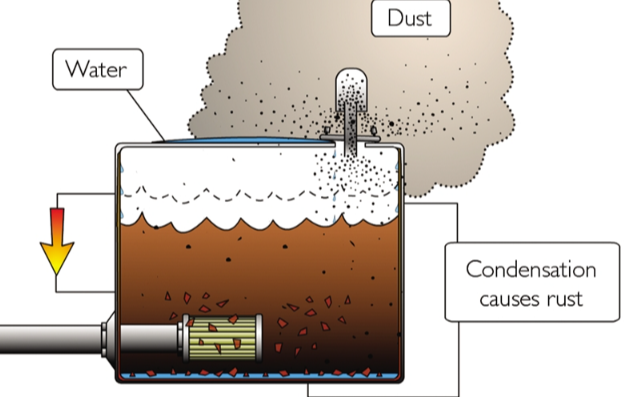

Contamination enters systems through multiple pathways. New fluid from suppliers often contains 500,000 particles per 100ml larger than 5 microns—exceeding most manufacturers’ cleanliness recommendations for operation. Worn seals allow dirt infiltration from outside. Breather caps without proper filtration pull in airborne dust every time reservoir fluid level changes. During maintenance, contaminated funnels and containers introduce foreign material.

Water contamination presents different but equally serious threats. Even small amounts of water—appearing as a milky fluid color—reduce lubrication effectiveness and promote rust formation on steel components. Water accelerates oxidation of the base oil and reacts with antiwear additives, forming acidic compounds that attack yellow metals like bronze valve bodies. In cold conditions, water can freeze in lines and valves.

Air contamination manifests as foam or entrapped bubbles. Aerated fluid compresses under pressure, making hydraulic responses spongy and unpredictable. When high-pressure air bubbles collapse through cavitation, they generate localized heating above 1,000°F and destructive shock waves that erode metal surfaces. Cavitation damage appears as pitted, sponge-like surfaces on pump faces and cylinder walls.

Proper filtration provides the primary defense against contamination. Industrial hydraulic systems typically require filtration to 10 microns absolute or finer. High-pressure systems with servo valves demand even stricter cleanliness levels. Filters must be changed before going into bypass mode, where contaminated fluid flows around saturated filter elements. Many operations use kidney loop filtration systems that continuously polish fluid in the reservoir while equipment runs.

Base oil alone cannot meet modern hydraulic system demands. Carefully engineered additive packages provide critical performance characteristics that separate quality fluids from cheap alternatives.

Antiwear (AW) additives, primarily zinc dialkyldithiophosphate (ZDDP), form protective chemical films on metal surfaces. Under the extreme pressure and temperatures at pump contact points, these films prevent metal-to-metal contact. Systems using fluids without adequate AW additives suffer rapid pump wear, particularly in high-pressure piston pumps operating above 3,000 psi.

Oxidation inhibitors slow the chemical reaction between oxygen and base oil molecules. Without these additives, oxidation accelerates at high temperatures, producing acidic byproducts that corrode components and form sludge. Quality fluids with strong oxidation resistance maintain their properties much longer between change intervals.

Viscosity index improvers help multigrade fluids maintain consistent viscosity across temperature ranges. These polymer additives expand at higher temperatures to maintain viscosity, though they permanently shear down under high mechanical stress. Mobile equipment with smaller reservoirs and high-power density particularly benefits from VI improvers that keep fluid in the optimal viscosity window.

Foam inhibitors modify surface tension to help trapped air bubbles break and release from fluid. Without foam control, agitated fluid in reservoirs froths like beer, allowing air to circulate through pumps and causing cavitation problems. Demulsifiers serve the opposite function for water, helping it separate and settle so it can be drained rather than circulating through the system.

Rust and corrosion inhibitors protect steel and yellow metal components from moisture damage. These additives form protective barriers on metal surfaces, preventing water and oxygen from initiating corrosion. This protection becomes especially critical in humid environments or systems with seasonal temperature cycling that promotes condensation.

The additive package quality directly correlates with fluid cost. Premium synthetic fluids may cost 3-5 times more than basic mineral oils, but they deliver superior protection, longer drain intervals, and better energy efficiency. For critical equipment or harsh operating conditions, the additional cost represents insurance against expensive failures.

Equipment performance varies measurably between fluid quality levels. A German hydraulic press manufacturer conducting controlled testing found that optimized high-VI hydraulic fluid reduced energy consumption up to 10% compared to conventional monograde reference fluid. The system also ran cooler, extending component life and reducing cooling system load.

Mobile construction equipment demonstrates even more dramatic differences. Excavators and loaders working in dusty conditions face constant contamination challenges. Operations using low-quality fluid with poor filtration capability experience pump failures within 2,000-3,000 operating hours. The same equipment running premium fluid with proper filtration systems routinely exceeds 10,000 hours between major repairs.

Temperature management illustrates another quality distinction. Standard mineral oils typically lose their lubrication properties above 180°F, while premium synthetics maintain performance to 250°F or higher. In high-ambient-temperature environments like desert mining operations, this extended temperature capability means the difference between reliable operation and frequent shutdowns for cooling.

Cold weather operation reveals similar gaps. Basic hydraulic oils may become too viscous to pump below 20°F, forcing operators to idle equipment for extended periods before use. Arctic-grade fluids with pour points below -40°F and carefully selected viscosity characteristics start and operate normally in extreme cold, maintaining productivity when standard fluids fail.

Industrial facilities tracking maintenance costs over multi-year periods consistently find that fluid quality investments reduce total ownership costs. One manufacturing plant documented 40% fewer hydraulic repairs after switching from bargain-priced bulk fluid to OEM-specified branded products. The improved reliability also reduced production interruptions, generating additional value beyond direct repair savings.

Selecting appropriate hydraulic fluid begins with understanding system requirements. Equipment manufacturers specify viscosity grades—typically ISO 32, 46, or 68 for industrial applications—based on pump design, operating pressure, and expected temperature range. These specifications reflect extensive testing to identify fluids that provide optimal protection and efficiency.

Climate-controlled indoor manufacturing environments can often use straightforward ISO 46 monograde fluids. The stable temperature eliminates the need for expensive multigrade formulations. Mobile equipment or systems in varying ambient conditions benefit from multigrade fluids that maintain viscosity across wider temperature spans.

Application environment influences other selection criteria. Fire-resistant fluids become necessary near ignition sources or hot surfaces, despite higher costs and special material compatibility requirements. Environmentally sensitive locations like forestry or marine applications require biodegradable fluids to minimize ecological impact from inevitable small leaks. Food-grade hydraulic equipment must use NSF-approved fluids safe for incidental food contact.

Once selected, fluid quality must be maintained through systematic monitoring. Oil analysis programs test samples at regular intervals for viscosity, contamination levels, water content, and additive depletion. Laboratory analysis detects problems early, often identifying issues before they cause noticeable performance degradation. A rising wear metal count signals component deterioration. Increasing viscosity indicates oxidation. Water detection prompts seal inspection.

Filter maintenance follows manufacturer schedules or pressure differential indicators. Waiting for bypass conditions wastes the filter’s protective value when it’s needed most. Breather filters prevent airborne contamination from entering reservoirs during normal thermal breathing cycles. Proper storage and transfer procedures for new fluid prevent introducing contamination before fluid even reaches the system.

Mixing different fluid brands or types creates compatibility risks. Some additives react negatively, precipitating out or forming sludge. When changing fluid types, systems should be thoroughly flushed following manufacturer procedures to remove residual old fluid. For critical systems, complete teardown and cleaning may be justified.

Change intervals depend on operating conditions, not arbitrary time schedules. Systems with excellent filtration operating in clean, temperature-controlled environments may run 5,000+ hours between changes. Harsh conditions with contamination, temperature extremes, or heavy use may require changes every 1,000-2,000 hours. Regular oil analysis provides data-driven change timing rather than guessing.

Mixing fluids of the same ISO grade and type (both AW mineral oils, for example) generally works if both meet system specifications. However, mixing introduces unknowns about additive compatibility. For critical equipment, avoid mixing or flush completely before switching brands. Always check with fluid manufacturers when in doubt.

Hydraulic fluid is the broader term encompassing any liquid used for power transmission in hydraulic systems, including water-based and synthetic types. Hydraulic oil specifically refers to petroleum-based fluids, the most common category. In casual use, the terms are often interchangeable.

Visual inspection reveals obvious problems—milky appearance indicates water, very dark color suggests oxidation, and visible particles mean filtration failure. However, many contamination types remain invisible. Professional fluid analysis detects particulate counts, water content, and chemical changes before they cause visible damage. Annual or semi-annual testing catches problems early.

Hydraulic fluid quality creates measurable competitive advantages that extend far beyond the fluid cost line item. Equipment reliability directly impacts operational efficiency—machines that run when needed complete work on schedule. Reduced downtime means projects finish on time, manufacturing lines hit production targets, and service operations meet commitments.

Energy efficiency gains from premium fluids compound over equipment life. A 6% efficiency improvement across a plant’s hydraulic systems can reduce annual energy costs by thousands or tens of thousands of dollars, depending on scale. These savings flow directly to bottom-line profitability.

Extended component life defers capital equipment replacement costs. Hydraulic pumps, motors, and valves represent major investments. Doubling or tripling component life through proper fluid selection and management reduces lifecycle costs substantially. The extended service life also improves resale value—well-maintained equipment with documented fluid programs commands premium pricing in used equipment markets.

Safety and environmental considerations matter increasingly to insurance carriers and regulatory agencies. Proper fluid management reduces fire risks, prevents environmental contamination from leaks, and eliminates high-pressure injection hazards from degraded systems. Companies with strong fluid maintenance programs often qualify for lower insurance premiums and avoid regulatory fines.

Fluid quality programs don’t require massive investments. The incremental cost difference between low-grade and premium hydraulic fluid typically amounts to 50-100% more per gallon. For a system holding 50 gallons, that’s $200-400 per fill. When compared against a single pump replacement costing $3,000-10,000, or a day of equipment downtime costing similar amounts, the insurance value becomes obvious.

The key lies in viewing hydraulic fluid as a critical component rather than a commodity. Systems designed to generate thousands of pounds of force at thousands of PSI cannot tolerate second-rate lubrication. Quality fluid protects investments, maintains uptime, and delivers measurable returns through reduced failures and improved efficiency. The question isn’t whether fluid quality matters—the question is whether you can afford to ignore it.