Menu

Professor Samuel Ting was awarded the Nobel Prize in Physics in 1976 in recognition of his experimental discovery of a new particle. In his acceptance speech, Professor Ting said in Chinese: “The backward notion that ‘those who work with their minds govern others, while those who work with their hands are governed by others’ has been very harmful to young people in developing countries. Because of this notion, many students in developing countries tend toward theoretical research and avoid experimental work. In fact, natural science theory cannot be separated from experimental foundation. Physics, in particular, is generated from experiments. I hope that my winning this prize can arouse the interest of students in developing countries and draw their attention to the importance of experimental work. Experimentation is the foundation of natural science. Theory without experimental verification is meaningless. When experiments overturn theory, only then can new theory be created, but theory cannot overturn experiments.“

If experimentation is so important for sciences that study theory, then for hydraulics—a practical technology that must face reality, solve real problems, and create social benefits—it should certainly not be neglected.

Unfortunately, some university hydraulics teachers are disconnected from practice and testing, turning “engineering hydraulics” into “formula hydraulics”: textbooks are filled with lengthy formulas, frequently using differential and partial differential equations, yet rarely containing test curves. Classes teach formulas, exams only test formulas and calculations, leading students to mistakenly believe that “the more formulas, the more advanced,” that hydraulics can be mastered through formulas alone, and that hydraulic systems can be designed through calculations alone. How naive!

Hydraulics deals with liquids! Even elementary school students know that liquids are vastly different from solids: solids have fixed shapes, while the shape of liquids changes with their container. The molecules of solids vibrate around their equilibrium positions, whereas liquid molecules, even when macroscopically at rest, undergo large-scale irregular random motion—Brownian motion. In fact, the most commonly used physical quantity in hydraulic technology—pressure itself—is a statistical parameter representing the sum of impact forces caused by liquid molecular motion. Even when left stationary, liquids will have different pressures at different levels due to gravity. In hydraulics, to transmit energy, liquids must be in motion. Even in so-called steady-state motion, in seemingly smooth and orderly laminar flow, the velocity at each point on the same cross-section of the flow channel differs, and thus the pressure at each point also differs—not to mention in transient and turbulent conditions. Furthermore, when subjected to external forces, the volume change of liquids is much greater than that of solids. Therefore, the uncertainty of liquids is much greater than that of solids, and we should not use the mindset for dealing with solids to handle liquids. Formulas in hydraulics are mainly used to analyze and demonstrate causal relationships, influencing factors, and trends—not for truly accurate calculations! More emphasis should be placed on actual measurements!

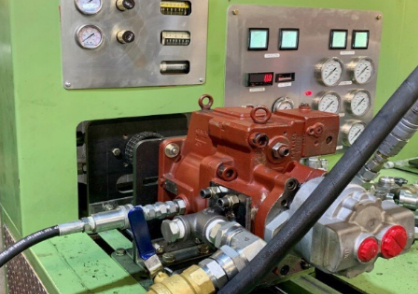

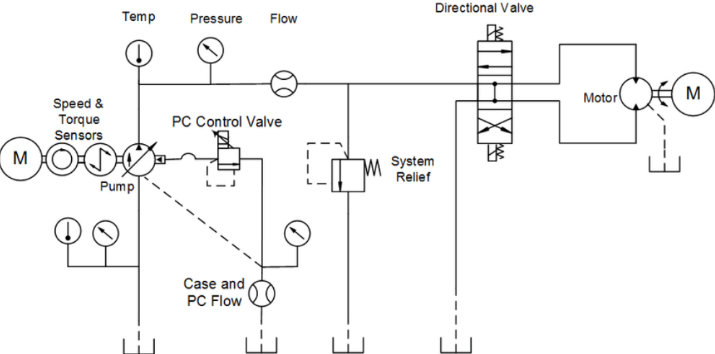

Regrettably, some university hydraulics laboratory courses still use pressure gauges invented 170 years ago, while digital testing instruments available for 40 years are still not dared to be used. As a result, graduate students studying hydraulics are at a loss when faced with test curves, only able to copy descriptions from lecture notes and textbooks at length, yet unable to explain test curves using Newton’s laws and Pascal’s law learned in middle school. This is truly lamentable.

This teaching philosophy that emphasizes theory over experimentation causes students many difficulties after graduating to work in enterprises and research institutions, requiring a long period of study before they can enter actual work. What a disservice to students!

Some professors teaching hydraulics still do not know how to use hydraulic testing instruments to this day. In the past, because of poverty, universities had no money to buy hydraulic testing equipment and had no testing conditions. Now the situation has completely changed—if testing is still not done, there are no more excuses.

Some professors teaching hydraulics argue that they are training research-oriented talent, so they need not focus on actual testing. They probably dare not say that IFAS is not training research-oriented talent. Yet precisely there, not a single research project is not closely connected with testing. Every doctoral student has at least one test bench dedicated to their use. Theoretical research that is not combined and compared with test results cannot become a paper, and would not pass even as a master’s thesis.

My experience learning hydraulic technology for nearly 50 years: formulas can more clearly describe the mutual influence relationships and trends among physical quantities, facilitating qualitative analysis. But learning formulas should serve hydraulic technology! Playing with formulas divorced from reality without clarifying their physical meaning is like a tree without roots—it cannot grow!

For practical hydraulic engineering and technical personnel, being able to master formulas that reveal the internal laws of hydraulics is certainly a good thing. But calculations should serve the analysis of actual working conditions, starting from practice, gradually increasing computational complexity, and applying as needed! It’s not that calculations aren’t needed, but they should match testing and processing capabilities—good enough is sufficient! Don’t spend too much energy on formulas, getting confused by tedious calculations divorced from reality, hindering progress. In fact, differential forms are only useful when studying transient states. If even steady states cannot be clarified, what is there to say about transient states? When beginning to learn hydraulics, it is completely possible not to involve advanced mathematics!

In learning hydraulics, more important than getting entangled in complex formulas is: organizing concepts, understanding essence, grasping causal relationships, and understanding influencing factors and trends of change. Spend more energy studying test curves—first steady, then transient!

Standing in front of a machine reciting Euler’s equation—that person is either a genius or a fool! For engineering and technical personnel, when receiving a task or encountering a problem, qualitative analysis always comes first. Then, based on the characteristic curves of some valves, further in-depth quantitative analysis is conducted.

Quantitative analysis should also go from rough to fine, progressing step by step. For example, for a certain parameter, first determine whether it should roughly be between 1 and 2, or between 8 and 9. Then, if necessary, further determine whether it is between 8.1 and 8.2 or between 8.8 and 8.9.

Although accurate calculation in hydraulic technology is impossible, but still some estimation should be done as much as possible to reduce blindness. For this reason, I have converted some calculation formulas related to hydraulic valves into an EXCEL spreadsheet estimation software “Hydraulic Valve Estimation 2023” as a complimentary resource for this book, to facilitate readers’ application and verification.

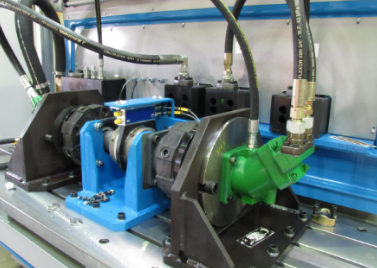

Testing must be given very, very high importance. Testing should be placed in the most important position in learning hydraulics. The ability to test and analyze the pressure and flow change processes of hydraulic systems should be a basic skill that master’s students and assistant engineers must master. Ask yourself: can one be an electrician without knowing how to use a multimeter? Then why should becoming a hydraulic assistant engineer not require knowing how to use a hydraulic “multimeter”?