Menu

Displacement refers to how much oil a pump can push per revolution. A 30cc gear pump theoretically pushes 30 milliliters per revolution; in practice it’s slightly less due to internal leakage, but it’s basically that amount and won’t change. Variable displacement pumps are different – they can adjust from zero to maximum displacement, with any value in between.

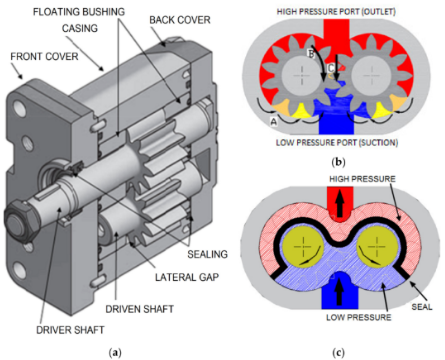

Gear pumps are the most common type of fixed displacement pump. In external gear types, two gears are mounted in a housing and rotate against each other, with the spaces between teeth carrying oil from inlet to outlet. Internal gear types have one large and one small gear nested together rotating. There’s also a type of gear pump that uses herringbone gears, which has less noise and pulsation than straight-cut gears. Regardless of type, once speed is set, flow is set. When system pressure rises, the gear pump keeps pushing oil; if it can’t push through, it forces open the relief valve and oil returns to tank through the relief valve. This process converts energy into heat. If the system operates for extended periods at demands below maximum flow requirement, this heat loss is considerable.

The principle of variable displacement in piston pumps starts with the swashplate. The shaft drives the cylinder block, which has a circle of holes, each containing a piston. The piston head has a slipper that rides against the swashplate. There’s an angle between the swashplate and shaft; as the piston follows the cylinder block through one rotation, it’s pushed in and released by the swashplate, completing one cycle of oil intake and discharge. Large swashplate angle means long piston stroke and large displacement. Small swashplate angle means short stroke and small displacement. Since the swashplate angle can be adjusted, displacement can be adjusted.

There are several ways to adjust swashplate angle. The most basic is pressure compensation – when system pressure exceeds the set value, control oil pushes a servo piston to bring the swashplate toward center position, reducing displacement so pressure stops rising. There’s also load-sensing control, which maintains a fixed pressure differential between pump outlet pressure and load pressure; when load is light the pump outputs less oil, when load is heavy the pump outputs more oil. Starting with the Komatsu PC200-5 and PC300-5 generation, excavators began widespread use of open-center load-sensing systems. Later came closed-center load-sensing, which is even more efficient. Kawasaki’s K3VLS, K5V, and K7V series supplied for excavators all follow this approach.

There’s measured data on efficiency differences. At the same 90 liters per minute flow and 207 bar working pressure, external gear pumps have total efficiency around 85%, requiring 36.5 kilowatts of input power. Bent-axis piston pumps have total efficiency around 92%, with input power of 33.75 kilowatts. The nearly 3 kilowatt difference all becomes heat in the oil. For an excavator working 10 hours a day, a gear pump produces 30 kilowatt-hours more heat than a piston pump. This heat must be removed by the radiator, so the radiator needs to be larger and fan power must keep up.

The advantage of gear pumps is toughness. The clearance between gear tips and housing is much larger than the clearance between piston pump pistons and cylinder bores; some particles in the oil won’t easily cause seizure. Changing filter elements every 500 hours is generally fine. When they break, repairs are simple – replacing a seal kit costs a few hundred yuan. Piston pumps have tight clearances at the micron level, requiring high oil cleanliness. Filter elements must be changed every 250 hours, and even more frequently in harsh conditions. Dirty oil entering the piston cylinder bores scores grooves; particles between slippers and swashplate wear the slippers round – this kind of damage can’t be repaired, only parts replaced. A rotating assembly set costs several thousand yuan.

Vane pumps fall between the two. The rotor rotates inside the stator ring, with vanes in rotor slots flung outward against the stator inner wall. There’s eccentricity between the stator ring and rotor; in one revolution, the cavities between vanes first enlarge to draw in oil then shrink to discharge oil. In fixed displacement vane pumps, the stator ring position is fixed with constant eccentricity. In variable displacement vane pumps, the stator ring can move and eccentricity can be adjusted. Adjusting to concentric eliminates displacement. Automotive power steering used to use many vane pumps; now with more electric power assist, they’re used less.

Screw pumps are also fixed displacement. Two or three screws mesh and rotate together, pushing oil along the helical grooves from one end to the other. Flow is smooth without pulsation, and noise is low. Many pumping stations on oil pipelines use these. Industrially they’re also popular for conveying high-viscosity fluids, such as syrup and resin.

Selection depends on application scenario. For a cylinder with one action where flow and pressure are consistent throughout, a gear pump is sufficient. For stamping presses where most of the cycle requires low-pressure high-flow for rapid advance and retraction, with only those few seconds of actual stamping requiring high pressure, using a gear pump wastes too much energy – you need a variable displacement pump. Excavators are more complex, with five or six actuators – boom, stick, bucket, swing, and travel – operating in rotation, each requiring different flow and pressure that constantly changes; load-sensing variable displacement pumps are essential. Early excavators with open-center systems paired with fixed displacement pumps existed, but they had high fuel consumption and insufficiently precise control; they’re basically unseen now.

Price differences depend on tonnage. Gear pumps for small equipment cost one or two thousand yuan. For 20-ton class excavators’ main pumps, variable piston pumps cost four to five thousand US dollars new, and refurbished ones still cost over four thousand. But you can’t install gear pumps on excavators to save money on the pump – the valve bank won’t match, and the entire hydraulic system architecture isn’t designed that way.