Menu

Hydraulic cylinders are the actuators in hydraulic systems, responsible for converting hydraulic energy into mechanical energy. The input to a hydraulic cylinder consists of fluid flow and pressure, while the output is linear velocity and force. The piston of a hydraulic cylinder performs linear reciprocating motion, delivering a limited linear displacement.

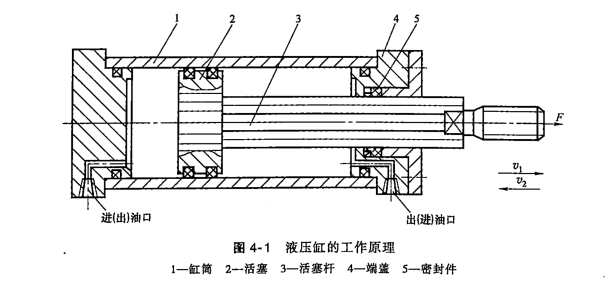

The working principle of a hydraulic cylinder is illustrated in Figure 4-1. A hydraulic cylinder consists of main components such as the cylinder barrel, piston, piston rod, end caps, and piston rod seals. Other types of piston hydraulic cylinders have similar main components to the structure shown in Figure 4-1.

If the cylinder barrel is fixed and hydraulic fluid is continuously fed into the left chamber, when the fluid pressure is sufficient to overcome all loads on the piston rod, the piston moves continuously to the right at velocity v, and the piston rod performs work on the external load. Conversely, when hydraulic fluid is fed into the right chamber, the piston moves to the left at velocity v, and the piston rod again performs work externally. This completes one reciprocating cycle. Such a hydraulic cylinder is called a fixed-cylinder type. If the piston rod is fixed and hydraulic fluid is continuously fed into the left chamber, the cylinder barrel moves to the left; when fluid is fed into the right chamber, the cylinder barrel moves to the right. This is called a fixed-piston-rod type. Unless otherwise specified, the hydraulic cylinders discussed in this chapter are of the fixed-cylinder, moving-piston-rod type.

Thus, the fluid entering the hydraulic cylinder must have pressure p and flow rate q. The pressure overcomes the load, while the flow rate determines the motion speed. The pressure and flow rate input to the cylinder represent the hydraulic energy, while the force and velocity of the piston acting on the load represent the mechanical energy output. Therefore, the input pressure p, flow rate q, output force F, and velocity v are the main performance parameters of a hydraulic cylinder.

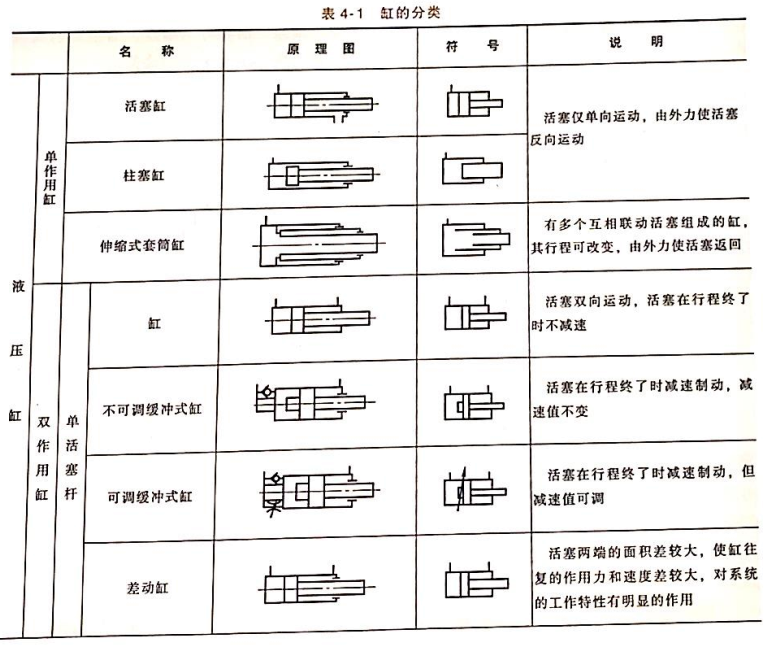

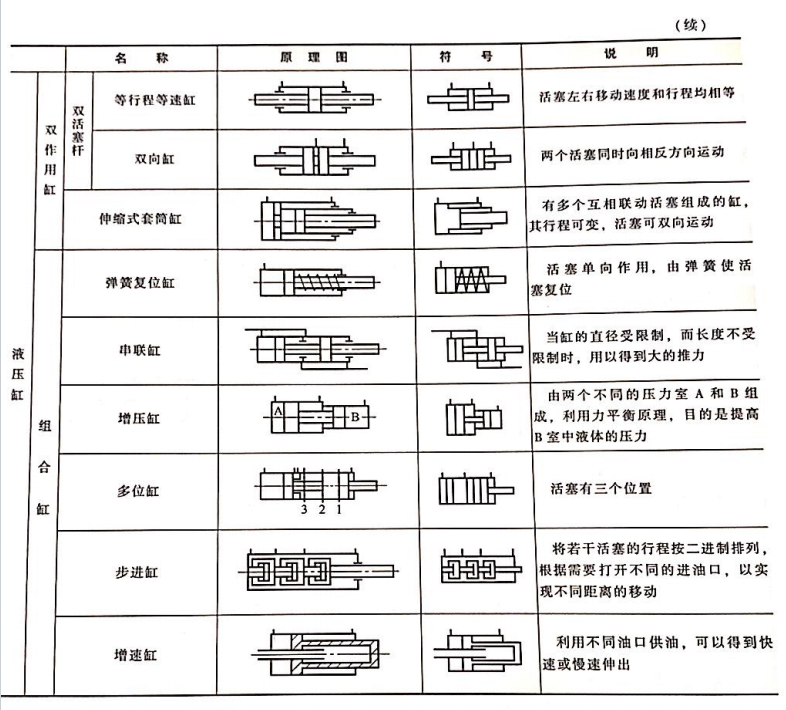

To meet the diverse needs of various applications, hydraulic cylinders are available in multiple types:

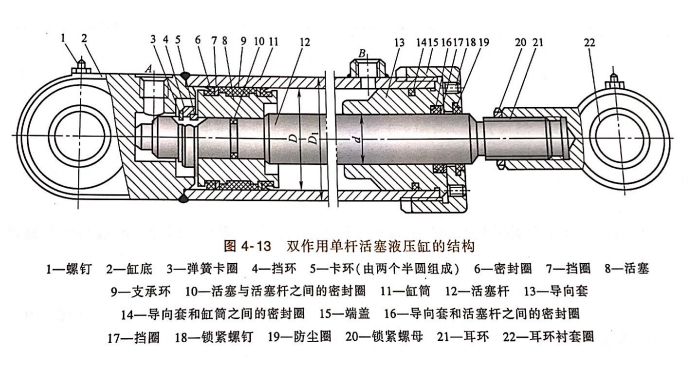

Figure 4-13 illustrates the structure of a double-acting single-rod piston hydraulic cylinder, commonly used in construction machinery. Its main components include the cylinder base (2), piston (8), cylinder barrel (11), piston rod (12), guide sleeve (13), and end cap (15). The structural features of this cylinder include:

The following sections describe the common structures of the main components of this hydraulic cylinder.

From Figure 4-13, the structure of a hydraulic cylinder can be divided into five main parts: cylinder barrel and end cap, piston and piston rod, sealing devices, buffering devices, and exhaust devices.

1.Cylinder Barrel and End Cap

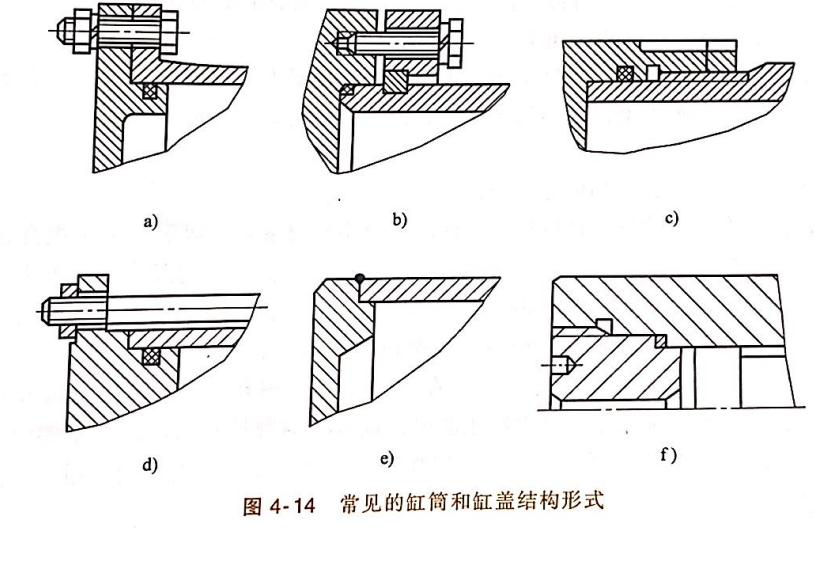

The structure of the cylinder barrel and end cap depends on the materials used. For working pressures p < 10 MPa, cast iron is used; for p < 20 MPa, seamless steel tubes are used; and for p > 20 MPa, steel or forged steel is used.

Common cylinder barrel and end cap structures are shown in Figure 4-14:

2.Piston and Piston Rod

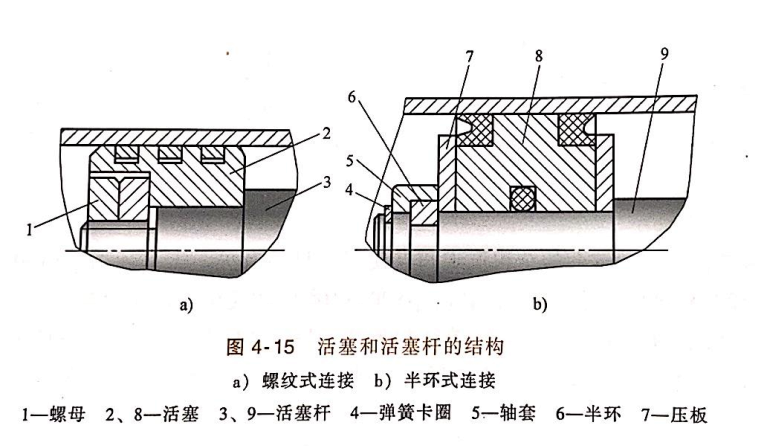

Piston and piston rod structures vary, including integral, taper pin, threaded, and half-ring connections, as shown in Figure 4-15.

3.Sealing Devices

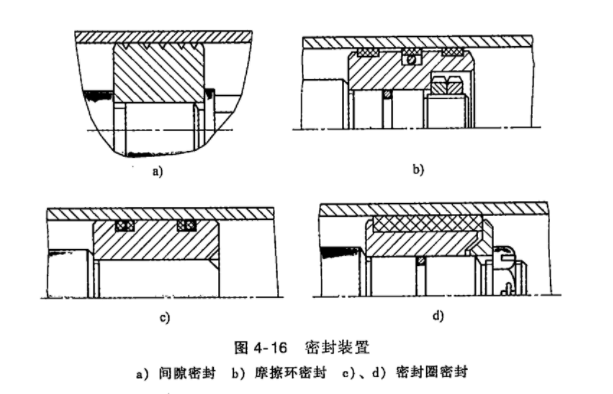

Common sealing devices in hydraulic cylinders are shown in Figure 4-16: