Menu

Hydraulic directional valves and directional control valves typically require replacement every 5-10 years under normal operating conditions, but certain demanding applications and environmental factors can accelerate wear to the point where annual replacement becomes economically justified. This occurs primarily when contamination levels exceed 75% of hydraulic system failure thresholds, when operating pressures consistently exceed design specifications, or when maintenance costs reach 20-35% of total operational expenses.

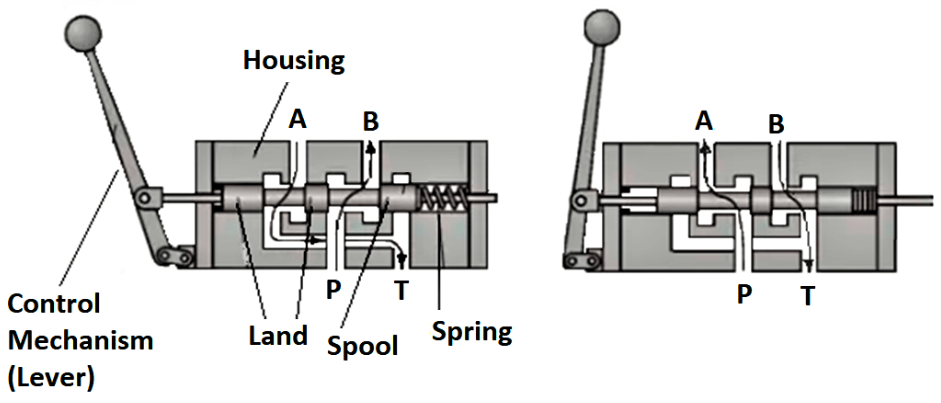

Directional control valves come in three main flavors, each with their own personality and failure tendencies. Spool valves slide back and forth, poppet valves bounce on springs, and rotary valves spin around. How these designs fail determines when you’ll need to replace them.

Spool valves work like precisely engineered sliding gates. Picture a finely machined cylinder (the spool) moving through a tight-fitting bore – where this cylinder stops determines which hydraulic ports connect together. The gaps between spool and bore are tiny, usually just 0.001-0.003 inches, which makes them incredibly sensitive to contamination.

When particulate contamination reaches levels exceeding 500,000 particles per 100ml (the maximum acceptable threshold according to industry standards), internal clearance spaces between spool and bore begin accumulating abrasive particles. Research indicates that particles equal in size to the clearance between moving surfaces cause jamming, while smaller particles (≤10 micrometers) form silt that erodes interior mating surfaces, rendering valves inoperable within accelerated timeframes.

Poppet valves function through spring-loaded seating mechanisms that open and close port access based on pressure differentials. These valves experience different failure modes, primarily seat wear and spring fatigue, which can progress rapidly under high-cycle applications where valve cycling exceeds 1 million operations annually.

Rotary valves utilize rotational motion to achieve directional changes, offering advantages in certain high-flow applications but presenting unique maintenance challenges related to seal integrity and bearing wear.

Here’s the thing about hydraulic valves – dirty fluid is their kryptonite. Studies show that 75% of hydraulic system failures trace back to contamination problems. It’s like having sand in your car engine; everything wears out much faster. The relationship between contamination levels and replacement frequency follows a predictable pattern that explains why annual replacement becomes necessary in severe operating environments.

Primary contamination sources include:

Each source contributes particles across different size ranges that impact valve performance through distinct mechanisms. Environmental contamination typically introduces larger particles (15-25 micrometers) that cause immediate mechanical interference, while wear debris consists of smaller metallic particles that create abrasive wear on precision surfaces over extended periods.

The velocity of degradation depends on the interaction between particle size distribution and valve clearances. Valves designed with 0.002-inch clearances experience accelerated failure when exposed to contamination levels exceeding MIL-H-5606F cleanliness requirements (10,000 particles 5-15 micrometers per 100ml). Under these conditions, valve lifespan can decrease by 40-60% compared to properly maintained systems.

Critical contamination thresholds for annual replacement:

Operating pressure significantly influences directional valve replacement frequency, with each 500 PSI increase above design specifications reducing expected service life by approximately 25%. This correlation becomes critical in applications where system pressures approach or exceed maximum rated values, transforming standard 5-10 year lifespans into annual replacement scenarios.

Pressure-related failure mechanisms include:

Cavitation damage occurs when fluid pressure drops below vapor pressure, creating micro-explosions that pockmark valve surfaces. This phenomenon becomes severe at pressures exceeding 3,000 PSI in systems without adequate pressure relief protection.

Seal degradation accelerates under continuous high-pressure operation, with temperature rises of 50°F above ambient reducing seal life by 50%. Annual replacement becomes justified when seal replacement costs approach 40% of valve replacement costs.

Internal leakage development follows pressure cycling patterns, with valves experiencing more than 10 pressure cycles per hour showing increased internal leakage rates that compromise system efficiency and require premature replacement.

Erosion patterns in high-pressure applications create distinctive wear signatures that can be used to predict replacement timing. Valves operating above 4,000 PSI show measurable erosion within 2,000-3,000 hours rather than the standard 8,000-10,000 hour service interval.

Industrial applications requiring annual replacement typically operate in pressure ranges exceeding 5,000 PSI, where valve design margins become insufficient for sustained operation without accelerated component degradation.

Environmental conditions create operating contexts that either extend or severely reduce directional valve service life, with temperature, humidity, and airborne contamination levels serving as primary determinants of annual replacement necessity.

Temperature extremes create the most significant environmental challenge, with both high and low temperature conditions accelerating valve deterioration through distinct mechanisms. Operating temperatures above 180°F (82°C) cause hydraulic fluid oxidation rates to double for every 18°F increase, leading to varnish formation that obstructs valve clearances. Conversely, temperatures below 0°F (-18°C) increase fluid viscosity beyond pump capability, causing starvation and increased wear during startup cycles.

Humidity effects prove particularly severe in applications with relative humidity exceeding 80%, where water ingress through breather systems increases moisture content beyond the 500 PPM threshold that triggers accelerated fluid degradation. This moisture contamination reduces oil life by 60% and creates corrosion on internal valve components.

Airborne contamination from industrial processes, construction environments, or agricultural applications introduces particulate matter that bypasses standard filtration systems. Systems operating in environments with particulate concentrations above 0.1 mg/m³ require annual valve replacement to maintain operational reliability.

Seasonal variations create thermal cycling that accelerates seal and elastomer degradation, with freeze-thaw cycles causing material embrittlement that compromises valve sealing integrity within annual operating cycles.

Different industrial applications create unique operating conditions that demand specific replacement frequency calculations based on actual service conditions rather than theoretical lifespan estimates.

Mining equipment applications experience severe operating conditions where directional valves operate in environments with high particulate contamination, extreme temperature variations, and continuous high-pressure operation. Case studies from gold mining operations demonstrate valve failure rates 300% higher than industrial averages, with maintenance costs representing 41% of total equipment operational expenses. Under these conditions, annual replacement becomes economically justified when downtime costs exceed replacement expenses.

Construction machinery presents different challenges related to start-stop operation patterns and varying load conditions that create pressure spikes and thermal cycling. Equipment operating in construction environments typically experiences valve lifespans reduced by 40% compared to controlled industrial applications, making annual inspection and potential replacement necessary for critical applications.

Agricultural equipment operates in dusty conditions with high levels of airborne contaminants that compromise filtration effectiveness. Tractors and harvesters operating in agricultural environments show contamination levels 200% higher than factory settings, requiring more frequent valve replacement to maintain system reliability.

Marine applications face salt water contamination risks and extreme environmental conditions that accelerate valve degradation. Salt exposure creates corrosion patterns on valve components that require annual replacement to prevent catastrophic failure.

Steel mill and foundry applications operate in high-temperature environments with significant particulate contamination from metal processing operations. These applications experience valve service life reductions of 50-70% compared to clean industrial environments.

The decision to implement annual directional valve replacement requires comprehensive economic analysis that considers replacement costs, downtime expenses, productivity losses, and system-wide impact factors.

Direct replacement costs for directional control valves range from 500−500-500−5,000 depending on size, pressure rating, and complexity, with annual replacement total costs (including labor and system downtime) typically ranging from 1,500−1,500-1,500−8,000 per valve.

Downtime costs associated with valve failure vary significantly by application, with industrial equipment downtime costing 200−200-200−2,000 per hour depending on production value. Mining operations experience downtime costs exceeding $5,000 per hour, making annual preventive replacement economically attractive compared to reactive replacement during production periods.

Maintenance cost analysis indicates that hydraulic system maintenance typically represents 20-35% of total operational expenses in severe service applications. Within this category, valve-related maintenance often accounts for 15-25% of total hydraulic maintenance costs, making annual replacement a predictable budget item rather than an emergency expense.

Productivity impact calculations for directional valve failures show that equipment operating with degraded valves experiences 15-30% reduction in operational efficiency, with associated productivity losses ranging from 10,000−10,000-10,000−50,000 annually per piece of equipment depending on application value.

Insurance and safety considerations create additional economic factors, with valve failures in critical applications potentially causing damage costs 10-50 times higher than replacement expenses. High-pressure hydraulic systems in industrial applications can experience catastrophic failure costs exceeding $100,000, making annual replacement insurance against major losses.

Optimizing directional valve maintenance intervals requires balancing preventive replacement costs against reactive maintenance expenses, with data-driven approaches providing the most accurate replacement timing predictions.

Condition-based monitoring provides the most accurate replacement timing through continuous assessment of valve performance parameters. Key monitoring parameters include pressure drop measurements across valve positions, internal leakage quantification, and response time measurements that indicate mechanical wear progression.

Predictive maintenance programs utilizing vibration analysis, thermal imaging, and fluid analysis provide early warning indicators of valve degradation, allowing replacement before catastrophic failure occurs. Systems implementing comprehensive predictive maintenance show 25-40% reduction in valve-related downtime.

Statistical failure analysis using Weibull distribution modeling helps predict failure probability curves based on operating conditions. Applications with failure rates exceeding 15% annually typically benefit from preventive replacement strategies.

Oil analysis programs provide contamination level tracking that correlates with valve wear rates, enabling replacement timing optimization based on actual operating conditions rather than fixed time intervals.

Performance trending of valve efficiency metrics (flow coefficient changes, pressure drop variations, response time changes) provides quantitative replacement decision criteria that eliminate guesswork from maintenance scheduling.

Understanding industry standards and benchmark performance data provides context for replacement frequency decisions and helps establish appropriate service life expectations for different operating conditions.

ISO 10770 standards establish cleanliness classifications and contamination limits that correlate directly with valve service life. Systems maintaining cleanliness levels better than ISO 16/13 (particle counts) show 200-300% longer valve service life compared to systems operating at ISO 20/17 levels.

API standards for hydraulic systems provide specific guidelines for inspection frequencies and replacement criteria based on criticality and operating conditions. Critical applications require inspection intervals of 1,000 hours with replacement criteria based on measured performance degradation rather than time-based schedules.

SAE research studies demonstrate that directional valves operating in properly maintained systems achieve service lives of 15,000-25,000 hours, while valves in contaminated or poorly maintained systems require replacement after 3,000-5,000 hours of operation.

Industry failure statistics indicate that directional valves in industrial applications experience failure rates of 2-5% annually, while valves in severe service applications (mining, construction, agricultural) show failure rates of 15-25% annually, supporting annual replacement strategies for severe duty applications.

Manufacturer warranty data provides performance expectations under various operating conditions, with most manufacturers offering 2-year warranties for industrial applications and 1-year warranties for severe duty service, reflecting expected service life under different operating conditions.

Implementing annual directional valve replacement requires systematic approach that ensures maximum benefit while controlling costs and minimizing operational disruption.

Risk assessment procedures evaluate application severity to determine replacement necessity, considering factors including contamination exposure, pressure cycling frequency, temperature extremes, and criticality of function.

Cost-benefit analysis models compare annual replacement costs against historical failure costs, productivity losses, and emergency maintenance expenses to justify replacement programs. Successful programs demonstrate 30-50% reduction in total valve-related costs over 3-year periods.

Inventory management strategies optimize replacement stock levels to minimize inventory carrying costs while ensuring availability for planned replacement activities. Bulk purchasing programs typically provide 20-30% cost savings compared to emergency replacement purchases.

Scheduling coordination with equipment maintenance cycles ensures replacement activities occur during planned downtime periods, minimizing production impact and labor costs. Integrated maintenance programs show 15-25% cost reductions compared to standalone replacement programs.

Performance tracking systems monitor replacement program effectiveness through maintenance cost tracking, downtime analysis, and equipment reliability metrics to optimize program parameters over time.

Training programs for maintenance personnel ensure proper installation procedures, quality control measures, and performance verification techniques that maximize replacement program effectiveness.

Assessment involves measuring contamination levels, monitoring operating pressures, tracking failure history, and calculating maintenance costs. Systems with contamination above 20,000 particles per 100ml, operating pressures exceeding design specifications by more than 20%, or showing valve-related downtime exceeding 40 hours annually typically benefit from annual replacement programs.

Critical indicators include internal leakage development (measurable pressure drop under static conditions), contaminated fluid analysis showing metal wear particles, pressure cycling exceeding design limits, or maintenance costs approaching replacement expenses. Immediate replacement becomes necessary when any combination of these factors creates system reliability concerns.

Extending service life requires maintaining fluid cleanliness below ISO 16/13 standards, operating within pressure specifications, implementing preventive maintenance programs, using appropriate fluid selection for operating conditions, and installing proper filtration systems. Systems maintaining these standards typically achieve 15,000-25,000 hour service life.

Contamination levels prove most critical, with each increase in particle count reducing service life exponentially. Operating pressure above design specifications and temperature extremes create secondary impacts, while application severity and maintenance quality complete the primary influence factors. Proper management of these factors can double or triple service life compared to poorly maintained systems.

The decision to implement annual hydraulic directional valve replacement requires comprehensive analysis of operating conditions, economic factors, and reliability requirements. While most systems operate effectively with 5-10 year replacement intervals, severe duty applications, contaminated environments, and high-criticality operations justify annual replacement programs that provide predictable costs, enhanced reliability, and optimized system performance. The key lies in matching replacement strategies to actual operating conditions rather than applying generic time-based maintenance approaches.