Menu

Hydraulic flow control valves reduce operational costs by optimizing fluid usage, preventing equipment damage, and minimizing energy waste. These valves regulate flow rates to match system requirements precisely, which lowers pump power consumption and extends component lifespan while reducing maintenance frequency.

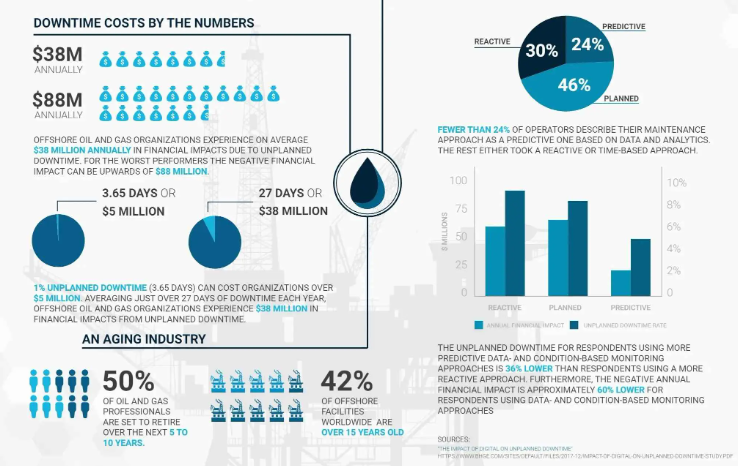

The financial impact becomes clear when you examine unplanned downtime costs. Manufacturing facilities lose between $39,000 to $2 million per hour during unexpected breakdowns, with these costs rising 50% since 2019 due to inflation and higher production demands. Flow control hydraulic valves prevent many of these failures by maintaining stable operating conditions and protecting downstream components from excessive pressure and flow fluctuations.

Flow control valves directly address one of the largest operational expenses in hydraulic systems: energy consumption. Industrial motors consume 25% of U.S. electrical energy, with pump systems representing the greatest opportunity for efficiency improvements and offering average savings of 20%.

The mechanism works through precise flow regulation. Without flow valve hydraulic controls, pumps operate at maximum output regardless of actual demand, forcing excess fluid through relief valves at full system pressure. This wastes substantial energy. A medium-sized 4/3 valve operating at 30 bar pressure drop with 60 liters per minute flow can dissipate approximately 7 kilowatts of power when both metering chambers open simultaneously.

Pressure-compensated flow control valves solve this problem by maintaining constant flow rates regardless of pressure variations. These hydraulic adjustable flow control valve systems automatically adjust to changing load conditions, ensuring actuators receive only the fluid they need. Research shows that modern electronic hydraulic flow control valve designs with digital control systems improve energy efficiency by up to 30% compared to conventional valves.

The energy savings manifest in several ways. First, reduced pressure drops mean less hydraulic power lost as heat. Second, optimized flow rates allow pumps to operate at lower speeds during partial load conditions. Third, preventing flow fluctuations eliminates the energy spikes that occur during system instability.

Consider the annual energy costs: hydraulic systems running continuously can consume 8,750 to 11,000 kilowatt-hours yearly, translating to $1,050 to $1,320 in energy costs at $0.12 per kilowatt-hour. Implementing proper hyd flow control valve technology can reduce these figures by 15-30% through better flow management and pressure optimization.

Preventative maintenance costs 3-5 times less than reactive maintenance, and hydraulic flow control valves play a central role in this cost differential. By maintaining stable flow rates and preventing pressure spikes, these valves protect expensive hydraulic components from premature wear and catastrophic failure.

The wear reduction occurs through several mechanisms. Flow control valve hydraulic systems prevent excessive speeds that cause accelerated wear on seals, bearings, and actuators. They eliminate pressure surges that can rupture hoses and damage pump components. They maintain optimal fluid velocities that reduce cavitation and erosion inside pipes and fittings.

Companies implementing comprehensive preventive maintenance programs report 30-50% reductions in unplanned downtime. The hydraulic flow control valve diagram shows how proper valve placement protects critical components by regulating flow before it reaches sensitive equipment. This upstream protection prevents damage cascades where one component failure triggers multiple downstream failures.

Temperature control represents another maintenance benefit. Excess flow generates heat through friction and turbulence. This heat degrades hydraulic fluid, reducing its lubrication properties and causing oxidation. Degraded fluid accelerates wear throughout the system. Flow hydraulic valve controls prevent these temperature excursions by matching flow rates to actual requirements, keeping fluid temperatures within optimal operating ranges.

Seal life particularly benefits from controlled flow rates. Seals fail prematurely when exposed to excessive pressure differentials or rapid flow changes. A hydraulic flow valve that maintains consistent conditions can extend seal life by 40-60%, significantly reducing replacement costs and the associated downtime.

The filter replacement schedule also improves. Systems with poor flow control generate more contamination through component wear and fluid degradation, requiring more frequent filter changes. Proper flow control hydraulic valve systems produce less contamination, extending filter life and reducing maintenance labor.

With proper maintenance enabled by effective flow controls, hydraulic systems can operate reliably for over 10 years, providing excellent return on investment. The initial cost of quality hydraulic flow control valves typically pays back within 12-18 months through reduced maintenance and downtime costs alone.

Unplanned downtime costs have become staggering. Beyond the immediate repair expenses, production losses, labor inefficiency, and missed delivery deadlines compound the financial impact. Hydraulic flow control valves prevent downtime through multiple protective mechanisms.

The primary protection comes from preventing sudden pressure changes. When actuators stop or start abruptly, pressure waves propagate through the hydraulic system. These pressure spikes can reach 2-3 times normal operating pressure, rupturing hoses, blowing seals, and fracturing metal components. Electronic hydraulic flow control valve systems with pressure compensation capability absorb these transients, maintaining system stability during operation changes.

Flow dividers within hydraulic valves manufacturer offerings enable synchronized operation of multiple actuators. This synchronization prevents the mechanical binding and component damage that occurs when actuators move at different speeds. Industries running synchronized equipment report 25-40% fewer mechanical failures compared to systems without proper flow division.

Predictive maintenance becomes possible with modern hydraulic valves incorporating diagnostic capabilities. These smart valves monitor flow rates, pressures, and temperatures continuously. Deviations from normal operating parameters trigger alerts before failures occur. This advance warning allows repairs during scheduled downtime rather than emergency shutdowns.

The cascade effect of prevented failures multiplies the cost savings. A single motor failure might seem localized, but if that motor drives equipment producing components for downstream operations, dozens of workers become idle while waiting for repairs. One study found that 70% of hydraulic system malfunctions stem from improper valve selection and usage, indicating enormous room for improvement through better flow control implementation.

Response time to process changes matters significantly. Hydraulic adjustable flow control valve configurations allow operators to modify system behavior quickly as production requirements shift. This flexibility prevents the need to stop equipment for reconfiguration, maintaining production flow and avoiding costly changeovers.

Hydraulic system efficiency extends beyond simple energy consumption to encompass overall system performance. Flow control valve hydraulic components optimize this performance by ensuring each actuator operates at its ideal speed and force profile.

Cycle time optimization represents a major efficiency gain. Without proper flow controls, actuators either move too slowly, wasting time, or too quickly, reducing precision and increasing mechanical stress. Hydraulic flow control valves enable engineers to tune each motion profile for optimal speed without sacrificing accuracy or component longevity.

The control valve market growth reflects this importance. Valued at $9.99 billion in 2024, the market projects to reach $17.07 billion by 2034, driven largely by automation adoption and energy efficiency demands. This 5.5% compound annual growth rate indicates industry recognition that proper flow control directly impacts profitability.

Load-sensing capabilities in advanced hyd flow control valve systems further enhance efficiency. These valves detect when actuators encounter varying loads and adjust flow rates accordingly. Light loads require less flow; heavy loads need more. This dynamic adjustment maintains consistent speeds while minimizing energy waste during lighter work phases.

Pressure zones created by reducing valves working alongside flow controls allow different system sections to operate at optimal pressures. Sensitive components receive lower pressures for protection, while high-force actuators get the pressure they need. This zoning prevents over-pressurizing delicate equipment while maintaining adequate power where required.

Fluid condition monitoring integrated into modern hydraulic flow control valves tracks oil degradation and contamination levels. Early detection of fluid problems prevents the efficiency losses and accelerated wear that contaminated oil causes. Systems can schedule fluid changes based on actual condition rather than arbitrary time intervals, reducing fluid costs while maintaining optimal performance.

The return on investment for quality hydraulic flow control valves typically manifests within 12-18 months through combined savings in energy, maintenance, and downtime prevention. Understanding proper installation and selection ensures these returns materialize.

Valve sizing represents the critical first decision. Undersized valves create excessive pressure drops, wasting energy and generating heat. Oversized valves operate inefficiently at low openings where control becomes imprecise. Engineers must calculate actual flow requirements, including peak demands and minimum flows, to specify appropriate valve capacities.

The hydraulic flow control valve diagram should account for pressure compensation needs. Systems experiencing significant pressure variations require pressure-compensated designs to maintain consistent flow rates. Applications with stable pressures may use simpler, less expensive valve configurations. The pressure differential across the valve during operation determines whether compensation proves cost-effective.

Temperature considerations affect both valve selection and system layout. Flow valve hydraulic components generate heat through throttling action. Installing valves where cooling airflow exists prevents heat buildup. Using synthetic hydraulic fluids with wider temperature ranges may justify higher upfront costs through extended component life and reduced maintenance.

Integration with automation systems multiplies the value of advanced electronic hydraulic flow control valve installations. These valves connect to programmable logic controllers, enabling coordinated control of entire production lines. The automation integration allows real-time adjustments based on product changeovers, quality requirements, or equipment condition monitoring.

Direct cost comparisons show compelling advantages. Preventative maintenance saves 12-18% compared to reactive approaches. Companies report 300-400% returns on preventive maintenance investments within the first year. The elimination of just one catastrophic failure often pays for an entire valve upgrade project.

Indirect benefits add substantial but harder-to-quantify value. Improved product quality from consistent actuator speeds reduces scrap rates. Enhanced worker safety through stable system operation avoids injury costs and regulatory penalties. Customer satisfaction improves when delivery schedules hold because equipment maintains reliable operation.

Different industries realize cost savings through flow control valves in ways specific to their operational requirements. Manufacturing facilities achieve precision in automated assembly lines where consistent actuator speeds ensure proper part fitment and reduce defect rates.

Construction equipment demonstrates particularly strong benefits. Excavators, loaders, and cranes use hydraulic flow control valves to regulate lifting speeds and prevent load swinging. This control protects both the equipment and surrounding structures while allowing operators to work faster with confidence. The material handling sector reports similar advantages, with forklifts and hydraulic jacks operating more safely and efficiently under proper flow control.

Agricultural machinery relies on flow valve hydraulic systems for implements like sprayers and tillers. Consistent flow rates ensure even chemical application across fields, reducing waste and improving crop yields. Harvesting equipment maintains optimal speeds regardless of crop density variations, maximizing throughput during time-sensitive harvest windows.

The oil and gas industry uses flow control hydraulic valve technology extensively in drilling operations and pipeline management. Pressure control capabilities prevent equipment damage from pressure surges while flow regulation ensures optimal drilling speeds. These applications often justify premium valve designs because the costs of production delays far exceed equipment expenses.

Manufacturing injection molding and stamping operations benefit from cycle time consistency. Hydraulic adjustable flow control valve installations allow precise control of press speeds, improving part quality while reducing energy consumption during non-critical motion phases. Some facilities report 15-25% cycle time reductions through optimized flow control compared to systems using simple throttle valves.

Mining and off-highway vehicles operate in harsh conditions where reliability proves essential. Hydraulic flow control valves designed for these environments withstand contamination, temperature extremes, and vibration while maintaining performance. The durability of quality valves reduces the maintenance burden in remote locations where service access costs more than the parts themselves.

Energy cost reductions typically range from 15-30% depending on system design and operating conditions. Systems with highly variable loads see greater savings because flow controls prevent pumps from running at maximum output during low-demand periods. The actual savings depend on duty cycles, pressure requirements, and how much time equipment spends at partial load versus full capacity.

Most installations achieve payback within 12-18 months through combined energy savings, reduced maintenance costs, and prevented downtime. High-utilization systems operating multiple shifts daily may reach payback in 6-9 months. The calculation should include avoided emergency repair costs and production losses, not just direct energy savings, for accurate ROI assessment.

Yes, flow control valve hydraulic components integrate into existing systems through retrofit installations. Engineers assess current system specifications, including pressure ranges, flow requirements, and contamination levels, to specify compatible valves. Some systems may need supporting modifications like filter upgrades or pressure relief valve adjustments, but complete system replacement rarely proves necessary.

Electronic hydraulic flow control valve systems offer superior precision and adjustment capability compared to mechanical designs. They enable remote control, automated adjustments based on process conditions, and diagnostic data collection. However, mechanical pressure-compensated valves provide excellent performance at lower cost for applications not requiring electronic features. The choice depends on control requirements, budget, and system integration needs.

The operational cost advantages of hydraulic flow control valves extend throughout equipment lifecycles. Beyond immediate energy and maintenance savings, these components protect capital investments by preventing catastrophic failures that force premature equipment replacement.

Proper valve selection starts with understanding actual system requirements rather than overspecifying for worst-case scenarios. Operating pressure ranges, flow rate variations, fluid types, and temperature conditions all factor into optimal valve selection. Manufacturers provide detailed specifications including flow coefficients and pressure compensation ranges that guide proper matching to applications.

System-level thinking amplifies individual component benefits. Combining flow controls with appropriate filtration, fluid management, and monitoring systems creates robust hydraulic installations that operate reliably for decades. The integration enables each component to perform its protective function while the whole system operates more efficiently than the sum of parts alone could achieve.

Training operators and maintenance personnel on flow control capabilities ensures the technology delivers expected results. Understanding how to adjust valve settings for different products or operating conditions allows systems to adapt to changing requirements without engineering intervention. This operational flexibility prevents production delays while optimizing efficiency across diverse workloads.

Documentation of valve settings, maintenance schedules, and performance metrics establishes baselines for comparison. When efficiency declines or problems emerge, having historical data accelerates troubleshooting by identifying when conditions changed. This information guides targeted repairs rather than time-consuming trial-and-error diagnosis.

Future-proofing considerations matter for long-term installations. Specifying valves with adjustment ranges beyond current needs accommodates production expansion or process changes without requiring valve replacement. Choosing designs with available upgrade paths to electronic control or diagnostic capability protects against obsolescence as automation requirements evolve.

The compounding nature of cost savings means improvements made today continue delivering value for years. Energy costs saved don’t just benefit one year’s budget – they reduce expenses throughout the equipment’s operating life. Similarly, prevented component failures avoid not only immediate repair costs but also the long-term effects of secondary damage that degraded components inflict on surrounding equipment.

Working with experienced hydraulic valves manufacturers ensures access to technical support during specification, installation, and operation. These partnerships provide valuable insights into application-specific challenges and solutions that generic product selection cannot address. The relationship often yields ongoing value through technology updates, troubleshooting assistance, and performance optimization recommendations.

Ultimately, hydraulic flow control valves represent strategic investments rather than simple component purchases. Their ability to reduce operational costs while improving reliability and performance makes them essential elements of competitive manufacturing and industrial operations. The financial returns and operational advantages they provide will continue justifying their adoption across industries seeking to optimize hydraulic system performance.