Menu

The mining industry represents one of the most demanding applications for hydraulic equipment, where robust, reliable, and high-performance systems are essential for operational success. Mining equipment such as excavators, haul trucks, and drills operate in challenging environments characterized by extreme temperatures, heavy loads, and abrasive materials, making the selection of an experienced hydraulic equipment supplier critical for mining operations worldwide.

Hydraulics Market Growth

The global Hydraulics Market size in terms of revenue is estimated to be worth $39.40 billion in 2026 and is poised to reach $44.26 billion by 2030, indicating continued growth and innovation in hydraulic technologies.

Table of Contents

Fundamental Principles of Mining Hydraulics

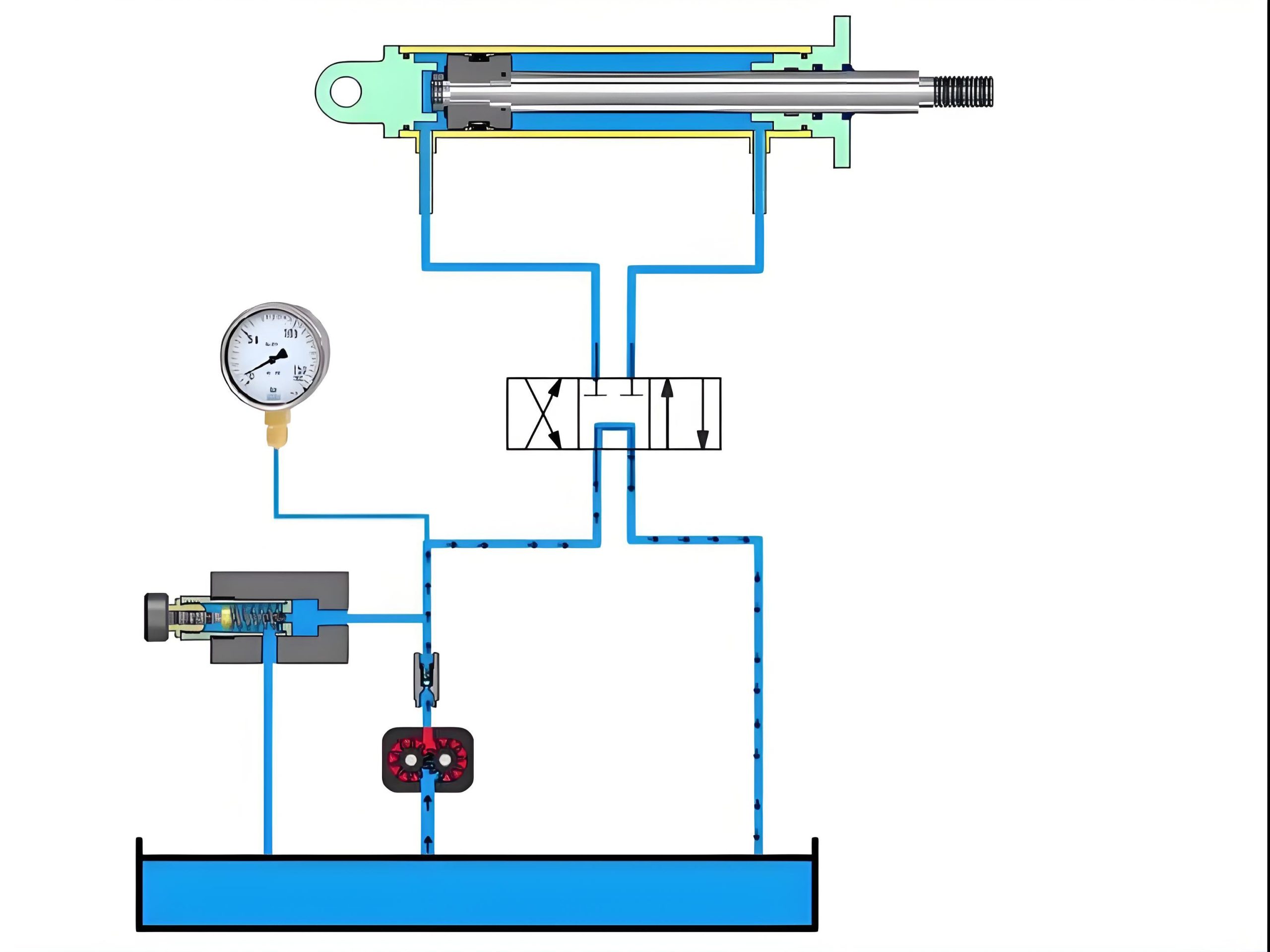

Hydraulic systems in mining applications operate on Pascal's principle, where pressure applied to a confined fluid is transmitted equally in all directions. This fundamental concept enables the generation of enormous forces necessary for mining operations through relatively compact systems.

The fluid power equipment is used to control, generate, and transmit power. They can produce high pressure and high force in compact volumes that can be monitored within a system by meters and gauges. These systems are designed to push, lift, rotate, pull, or grip almost any load encountered in mining environments.

The hydraulic fluid, typically specialized mineral oil or synthetic alternatives, serves multiple functions beyond power transmission. It provides lubrication for moving components, heat dissipation from the system, and contamination control through filtration systems.

Extreme Operating Conditions

In mining applications, hydraulic fluids must withstand extreme temperature variations:

- Sub-zero conditions in Arctic mines

- High temperatures in underground operations exceeding 60°C (140°F)

Core Hydraulic Components in Mining Applications

Hydraulic Pumps: The Heart of Mining Systems

Hydraulic pumps serve as the primary power source in mining hydraulic systems, converting mechanical energy from diesel engines or electric motors into hydraulic energy. The selection of pump types depends on specific mining applications, flow requirements, and pressure demands.

Fixed Displacement Pumps

Used in applications requiring constant flow rates, such as conveyor systems.

Pressure range: Up to 250 bar (3,625 PSI)

Common types: External gear pumps

Variable Displacement Pumps

Offer superior efficiency for dynamic mining operations with load-sensing capabilities.

Pressure range: Exceeding 450 bar (6,525 PSI)

Common types: Axial piston pumps

Radial Piston Pumps

Utilized in high-pressure, low-flow applications like hydraulic rock breakers.

Pressure range: Up to 700 bar (10,150 PSI)

Key trait: Exceptional durability

Hydraulic Motors: Converting Hydraulic Power to Mechanical Motion

Hydraulic motors in mining applications must deliver substantial torque while maintaining precise speed control and withstanding harsh environmental conditions. The motor selection process considers factors including torque requirements, speed ranges, efficiency characteristics, and mounting configurations.

-

Gear Motors

Robust, cost-effective solutions for moderate torque applications like conveyor drives.

-

Vane Motors

Offer smooth operation and good starting torque for applications like rotary tables.

-

Piston Motors

Deliver highest power-to-weight ratios for demanding applications like haul truck wheel drives.

Efficiency comparison of hydraulic motor types across different operating pressures

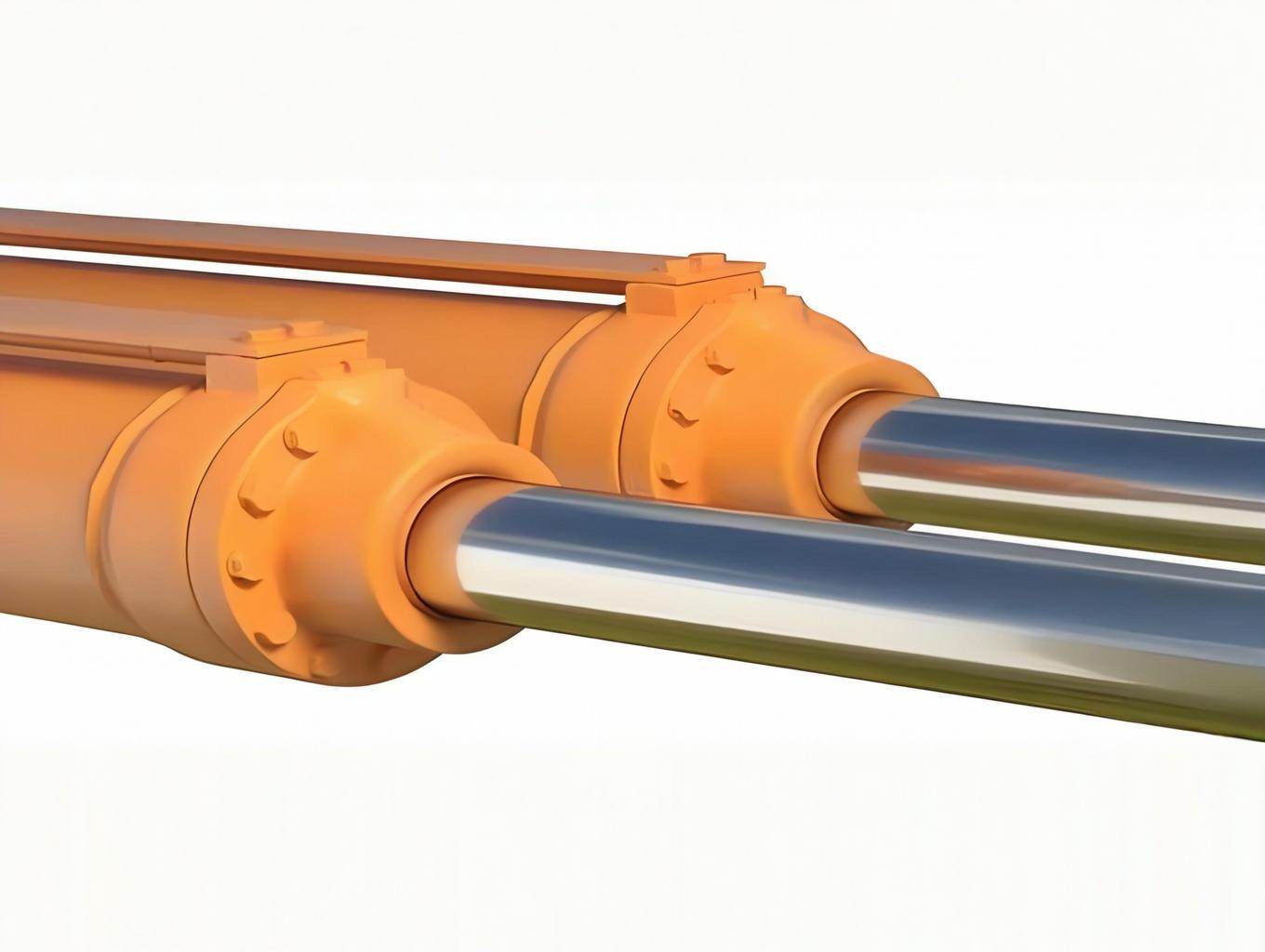

Hydraulic Cylinders: Linear Power Transmission

Single-acting Cylinders

Employed where spring return or gravity provides the return force, such as dump truck bed lifting.

Double-acting Cylinders

Represent the majority of mining applications, providing controlled extension and retraction movements.

Telescopic Cylinders

Enable extended stroke lengths in compact installations, achieving stroke-to-closed length ratios exceeding 4:1.

Mining operations rely heavily on hydraulic cylinders for various lifting, pushing, and positioning tasks. The extreme forces and environmental conditions in mining necessitate specialized cylinder designs and materials that only an experienced hydraulic equipment supplier can properly specify for each unique application. Heavy-duty construction with chrome-plated rods, high-tensile steel barrels, and specialized sealing systems ensures reliability under extreme loads and environmental conditions.

Hydraulic Valves: System Control and Safety

The valve systems in mining hydraulics serve critical functions in controlling flow, pressure, and direction while ensuring operational safety and equipment protection.

| Valve Type | Function | Mining Applications |

|---|---|---|

| Directional Control Valves | Manage fluid flow paths throughout hydraulic systems |

|

| Pressure Control Valves | Maintain system safety through pressure regulation and relief |

|

| Flow Control Valves | Regulate fluid flow rates to control actuator speeds |

|

| Check Valves | Prevent reverse flow and maintain load holding |

|

Mining-Specific Hydraulic Applications

Surface Mining Operations

Surface mining operations present unique hydraulic challenges requiring specialized equipment and systems designed for maximum productivity and reliability. These operations demand hydraulic systems capable of handling extreme loads while maintaining precision control in often harsh environmental conditions.

Large Excavators

Modern mining excavators feature bucket capacities exceeding 40 cubic meters and operating weights surpassing 800 tons.

- Operating pressures up to 350 bar (5,075 PSI)

- Flow rates exceeding 2,000 liters per minute

- Advanced load-sensing systems with up to 15% fuel savings

Haul Trucks

Mining haul trucks rely on hydraulic systems for steering, braking, suspension, and body lifting functions.

- Handling loaded weights exceeding 400 tons

- Dump systems generating over 3,000 kN of lifting force

- Multiple redundancy levels in power steering systems

Drilling Equipment

Drilling equipment employs sophisticated hydraulic systems for feed control, rotation, and percussion functions. These systems must maintain precise control while delivering substantial power to penetrate various geological formations.

Rotary Drilling Rigs

- Variable displacement motors for precise rotation control

- Torque characteristics optimized for varying geological conditions

Percussion Drilling Systems

- High-frequency hydraulic hammers operating at up to 200 bar

- Impact frequencies reaching 3,000 blows per minute

- Advanced accumulator systems for consistent impact force

Underground Mining Operations

Underground mining presents additional challenges including space constraints, ventilation requirements, and specialized safety considerations that influence hydraulic system design and selection. These environments demand compact, reliable systems with enhanced safety features.

Continuous Miners

Utilize hydraulic systems for cutting head positioning, conveyor operation, and tramming functions in confined underground spaces.

Hydraulic mining utilizes continuous miners to mine entries to gain access to production panels. Once a production panel is established, high-pressure water cannons are used to break the coal off the face.

Load-Haul-Dump Vehicles

Versatile underground mining equipment relying extensively on hydraulic systems for drive, steering, bucket operation, and articulated frame control.

Hydraulic drive systems must provide excellent traction control and precise speed regulation in confined underground environments, requiring careful system design consultation.

Roof Support Systems

Employ hydraulic-powered supports capable of supporting roof loads exceeding 1,000 tons per support unit.

- Specialized high-pressure hydraulic cylinders

- Advanced sealing systems for extended maintenance intervals

- Electrohydraulic control valves for remote operation

Underground Drilling Equipment

Requires compact, powerful hydraulic systems for rock drilling applications in confined spaces.

- Operating pressures up to 200 bar (2,900 PSI)

- Percussive frequencies optimized for specific rock hardness

- Compact designs for maneuverability in tight spaces

Advanced Hydraulic Technologies in Modern Mining

Electronic and Digital Control Systems

Modern mining hydraulic systems increasingly incorporate electronic control technologies to enhance performance, efficiency, and operator capabilities. Digital hydraulic valves offer great advantages such as high-power density, precise control and large force output, revolutionizing traditional valve control systems.

Electrohydraulic Systems

Combine electronic control with hydraulic power transmission, enabling precise, programmable control of mining equipment functions. These systems feature closed-loop control algorithms that continuously monitor system parameters and adjust hydraulic flow and pressure accordingly.

CAN Bus Communication

Enables integration of hydraulic system data with overall machine control systems. Real-time monitoring of hydraulic parameters including pressure, temperature, flow rates, and contamination levels provides operators and maintenance personnel with comprehensive system status information.

Load-Sensing Systems

Represent advanced hydraulic technology where pump output automatically adjusts to match system demand. This technology results in significant energy savings, reduced heat generation, and extended component life in mining applications.

Smart Hydraulic System Benefits

Energy Efficiency

+20%

Precision Control

+35%

Component Life

+40%

Productivity

+15%

Maintenance Costs

-25%

Filtration and Contamination Control

Mining environments present severe contamination challenges for hydraulic systems. Dust, debris, water, and temperature extremes can significantly impact system reliability and component life. Effective contamination control is therefore critical to maintaining hydraulic system performance in mining operations.

Advanced Filtration Systems

Incorporate multiple filtration stages including suction strainers, pressure filters, return filters, and offline filtration systems.

Proper filtration system design with beta ratios exceeding 1000 ensures contamination particles larger than 3 microns are effectively removed.

Breather Systems

Prevent atmospheric contamination while allowing thermal expansion and contraction of hydraulic reservoirs.

Silica gel dessicant breathers maintain low moisture levels in hydraulic fluid, preventing corrosion and extending component life.

Contamination Monitoring

Provide real-time assessment of hydraulic fluid cleanliness levels through advanced sensor systems.

Optical particle counters and water content sensors enable predictive maintenance strategies and optimal filter change intervals.

Hydraulic Fluid Technologies for Mining Applications

High-Performance Hydraulic Fluids

Mining hydraulic systems require specialized fluids capable of withstanding extreme operating conditions while maintaining consistent performance characteristics. The selection of appropriate hydraulic fluid is critical to system reliability, component life, and overall operational efficiency.

Mineral-Based Hydraulic Fluids

With advanced additive packages provide excellent lubrication properties and thermal stability for most mining applications.

Anti-wear additives

Oxidation inhibitors

Viscosity improvers

Wide temperature range

Synthetic Hydraulic Fluids

Offer superior performance characteristics including enhanced thermal stability and improved low-temperature fluidity.

PAO formulations

Polyol esters

Extended service intervals

Extreme temperature performance

Fire-Resistant Hydraulic Fluids

Essential in underground mining applications where fire hazards exist, providing varying degrees of fire resistance.

Water glycol

Synthetic esterSynthetic ester

Phosphate ester

Underground applications

Biodegradable Hydraulic Fluids

Address environmental concerns in sensitive mining areas while maintaining adequate performance characteristics.

Vegetable oil-based

Synthetic ester

Rapid biodegradability

Environmental compliance

Fluid Condition Monitoring

Oil Analysis Programs

Enable predictive maintenance strategies through regular monitoring of hydraulic fluid condition.

- Spectroscopic analysis for wear metals

- Contamination level assessment

- Additive depletion monitoring

Particle Counting

Quantifies contamination levels using ISO 4406 cleanliness codes to ensure system integrity.

- ISO 4406 cleanliness coding

- Target codes: 19/17/14 or better

- Correlation with component life

Water Content Analysis

Identifies moisture contamination that can cause corrosion, cavitation, and reduced lubrication.

- Corrosion prevention monitoring

- Target levels below 500 ppm

- Hydraulic fluid degradation tracking

Maintenance and Service Considerations

Preventive Maintenance Strategies

Regular maintenance and servicing are essential to ensure the continued functionality and longevity of these assets in mining operations. Comprehensive maintenance programs, often developed in partnership with the original hydraulic equipment supplier, address hydraulic system components systematically to prevent costly failures and production interruptions.

Scheduled Component Inspection

Includes regular examination of hydraulic hoses, fittings, cylinders, and reservoirs to identify potential issues before they escalate.

Key Inspection Points:

- • Hose condition and fitting integrity

- • Cylinder rod scoring or corrosion

- • Reservoir contamination levels

- • Seal integrity and leakage points

- • Connection tightness verification

Hydraulic Fluid Analysis

At regular intervals enables trending of system condition and early identification of developing problems before they cause failures.

Analysis Parameters:

- • Viscosity at operating temperature

- • Acid number and oxidation levels

- • Water content and contamination

- • Particle count and size distribution

- • Wear metal concentrations

Filter Maintenance Programs

Ensure optimal filtration effectiveness through regular element replacement and system cleanliness verification protocols.

Maintenance Elements:

- • Filter element replacement scheduling

- • Differential pressure monitoring

- • Bypass indicator verification

- • Filter housing inspection

- • System flushing procedures

Troubleshooting and Diagnostics

Pressure Testing

Verifies proper system operating pressures and identifies components with internal leakage or excessive pressure drop that can reduce system efficiency and performance.

Portable test equipment enables field testing of individual system circuits, allowing technicians to isolate problems without removing major components from service.

Flow Testing

Measures actual flow rates compared to specified values, identifying pump wear, internal leakage, or flow restriction problems that impact system performance.

Flow testing equipment must accommodate the high flow rates typical in mining hydraulic systems, often exceeding 2,000 liters per minute in large excavators and haul trucks.

Temperature Monitoring

Identifies overheating conditions that can lead to premature component failure, fluid degradation, and reduced system efficiency.

Normal Operating Range

30-50°C

Caution Zone

50-60°C

Critical Range

60°C+

Infrared temperature measurement enables non-contact monitoring of critical system components, identifying hot spots that indicate internal leakage or inefficiencies.

Safety Considerations in Mining Hydraulics

Pressure Safety Systems

Mining hydraulic systems operate at extremely high pressures requiring comprehensive safety measures to protect personnel and equipment. Properly designed safety systems prevent catastrophic failures and protect workers from serious injury.

Pressure Relief Valves

Provide primary protection against pressure overload conditions that could cause system failure or component rupture.

- Must be properly sized for system flow rates

- Regular testing to ensure proper function

- Set pressure below component rating limits

Accumulator Safety

Requires special attention due to the stored energy potential in high-pressure accumulators that can cause serious injury if released unexpectedly.

- Safety blocks for isolation during maintenance

- Pressure gauges for verification before service

- Proper charging and discharge procedures

Lockout/Tagout Procedures

For hydraulic systems must address stored energy in accumulators and elevated system components to prevent accidental activation during maintenance activities.

Energy Isolation

Securely isolate all energy sources to prevent unexpected startup

Lockout Devices

Apply approved lockout devices to energy isolation points

Tagout Documentation

Attach tags identifying responsible personnel and service nature

Verification

Confirm zero energy state before commencing work

Personnel Safety Training

Hydraulic Safety Training

Programs educate mining personnel about high-pressure hydraulic hazards and proper maintenance procedures to prevent accidents and injuries.

1

Injection Injury Prevention

Training on recognizing risks of high-pressure fluid injection and proper PPE requirements

2

Stored Energy Dangers

Education on hazards of stored energy in accumulators and proper release procedures

3

Maintenance Protocols

Proper procedures for safe maintenance, repair, and component replacement

Emergency Response Procedures

Address hydraulic system failures including major fluid leaks, component failures, and pressure-related emergencies to minimize injury risk.

1

System Shutdown

Procedures for safe emergency shutdown of hydraulic systems during failures

2

Injury Response

Proper first aid for hydraulic fluid injection injuries and pressure-related trauma

3

Hazard Containment

Methods for containing fluid spills and preventing environmental contamination

Future Trends and Economic Considerations

Electrification and Autonomous Systems

Mining industry trends toward electrification are influencing hydraulic system design. Electric-driven hydraulic pumps offer improved efficiency and reduced emissions compared to traditional diesel-driven systems, aligning with environmental regulations and sustainability goals.

Hybrid Power Systems

Combine electric and hydraulic power transmission to optimize efficiency across varying load conditions. Energy recovery systems capture hydraulic energy during lowering operations and convert it back to electrical energy, reducing overall power consumption.

Autonomous Mining Equipment

Almost every stage of mining requires hydraulic systems. Autonomous mining operations require hydraulic systems with enhanced reliability and remote monitoring capabilities to operate without direct human intervention.

Remote Monitoring Systems

Enable real-time hydraulic system status monitoring from central control rooms, allowing for proactive maintenance and issue resolution.

- Satellite communication for remote locations

- Real-time performance analytics

- Automatic alert systems for异常 conditions

Predictive Maintenance Technologies

Utilize machine learning algorithms to predict hydraulic component failures before they occur, minimizing downtime and maintenance costs.

- Advanced sensor systems for continuous monitoring

- Pattern recognition for early problem detection

- Optimized maintenance scheduling

Economic Considerations and ROI

Total Cost of Ownership

Hydraulic equipment selection for mining applications must consider total cost of ownership including initial cost, operating expenses, maintenance requirements, and productivity impact.

Energy Efficiency

Directly impacts operating costs in mining operations with significant fuel consumption.

Modern systems: 10-20% fuel savings

Maintenance Costs

Represent a significant portion of total ownership costs that can be minimized with proper practices.

Quality components: 30-40% lower costs

Productivity Impact

Hydraulic system reliability directly affects uptime and operational efficiency.

Downtime costs: $50,000+ per hour

The mining industry's reliance on hydraulic systems continues to grow as mining operations become larger, deeper, and more complex. Success in mining hydraulic applications requires comprehensive understanding of system design principles, component selection criteria, maintenance requirements, and safety considerations.

As mining operations continue to evolve with autonomous equipment, electrification trends, and environmental considerations, hydraulic systems must adapt to meet these changing requirements while maintaining the reliability and performance that mining operations demand. The future of mining hydraulics lies in intelligent, efficient, and environmentally responsible systems that continue to provide the power and precision essential for successful mining operations worldwide.