Menu

Hydraulic Valves

Hydraulic systems have revolutionized industrial machinery by enabling the transmission of power through pressurized fluid. At the heart of these systems lies a critical component: the Hydraulic valve. A Hydraulic valve serves as a control mechanism that regulates the flow, pressure, and direction of hydraulic fluid within a circuit.

The development of hydraulic technology can be traced back to ancient civilizations, but modern hydraulic systems emerged during the Industrial Revolution. However, it wasn't until the 20th century that the Hydraulic valve evolved into the precise, reliable component we recognize today.

In any hydraulic system, the Hydraulic valve functions as a traffic controller, directing fluid flow to where it's needed and preventing it from going where it's not. This regulation is essential for converting hydraulic energy into mechanical work efficiently and safely.

The importance of Hydraulic valve technology cannot be overstated. These components make possible the precise control of heavy machinery, enabling operations that would be impossible with mechanical or electrical systems alone. From manufacturing plants to construction sites, Hydraulic valve systems power the modern world.

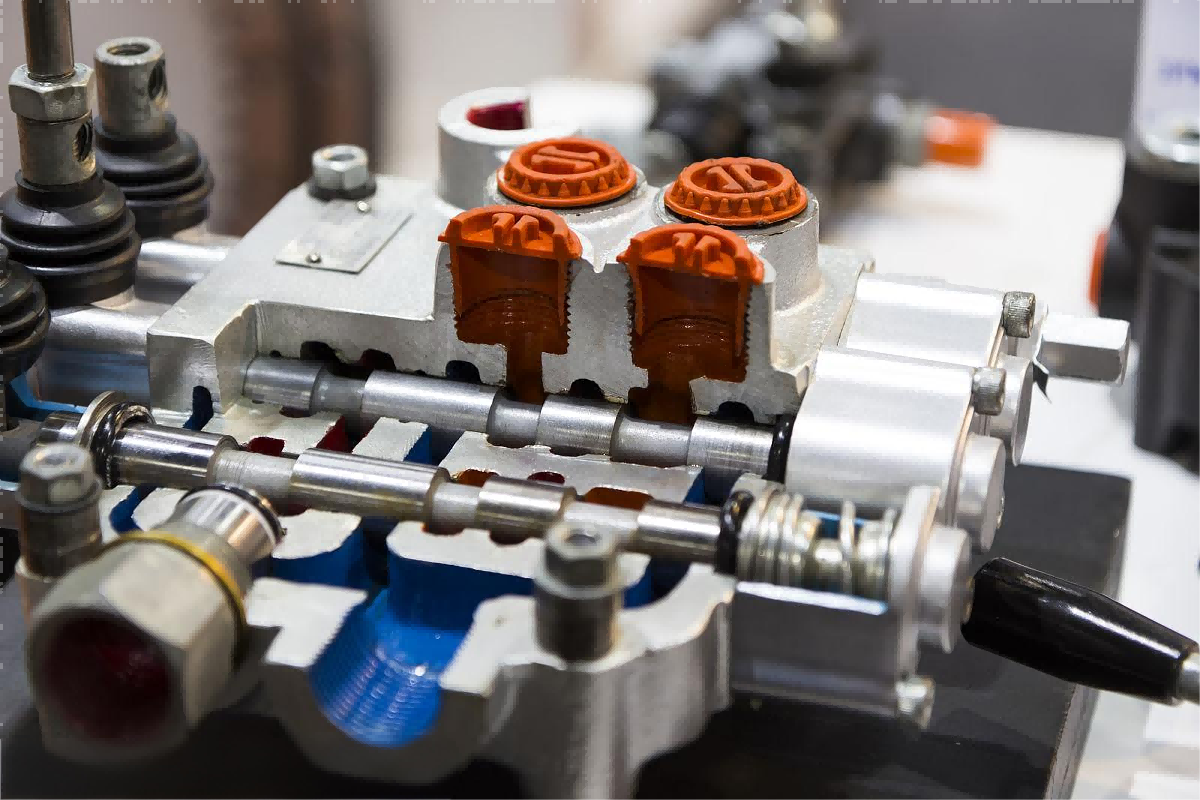

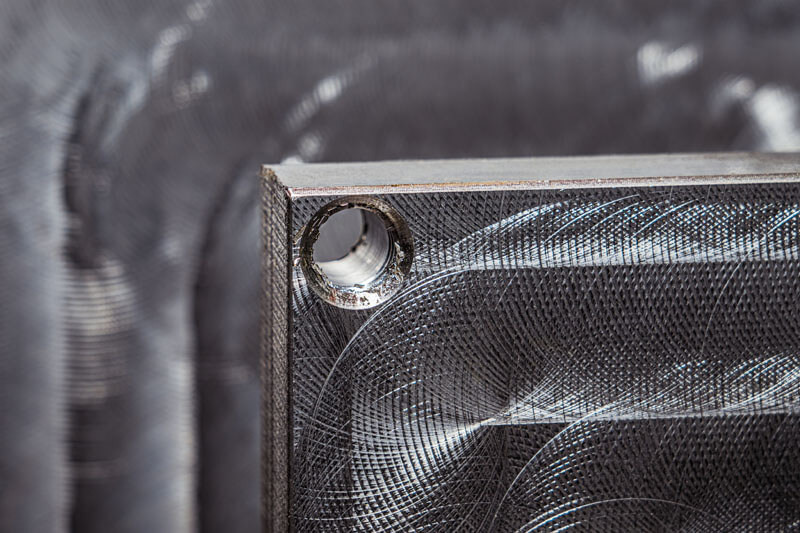

Cross-sectional view of a precision Hydraulic valve showing internal components

Key Takeaways

- A Hydraulic valve controls fluid flow, pressure, and direction in hydraulic systems

- Modern Hydraulic valve designs evolved significantly during the 20th century

- Hydraulic valve technology enables precise control of heavy machinery

- These components are essential for converting hydraulic energy to mechanical work

Fundamental Working Principles

To understand how a Hydraulic valve operates, we must first grasp the basic principles of hydraulics. Hydraulic systems work on Pascal's Law, which states that pressure exerted anywhere in a confined incompressible fluid is transmitted equally in all directions throughout the fluid. A Hydraulic valve manipulates this pressure and flow to control system behavior.

Flow Control

A Hydraulic valve regulates the volume of fluid passing through a circuit. By restricting or opening flow paths, the valve controls the speed at which actuators (cylinders or motors) operate.

Pressure Regulation

Certain Hydraulic valve types maintain system pressure within safe operating limits, preventing damage to components while ensuring sufficient force generation.

Directional Control

A Hydraulic valve can redirect fluid flow, determining which components receive pressure and enabling functions like extending/retracting cylinders or reversing motor direction.

The Physics Behind Hydraulic Valves

At its core, a Hydraulic valve operates by modifying the flow characteristics of hydraulic fluid. This involves several key physical principles:

Bernoulli's Principle

As fluid passes through a restriction in a Hydraulic valve, its velocity increases while pressure decreases. This principle is crucial for flow control valves that use variable orifices to regulate flow rate.

Laminar vs. Turbulent Flow

A well-designed Hydraulic valve minimizes turbulent flow, which causes energy loss and increased wear. Laminar flow through the valve ensures efficient operation and predictable performance.

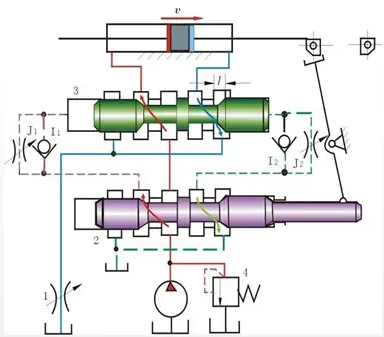

Pressure-flow relationship in a typical Hydraulic valve

Schematic representation of Hydraulic valve operation within a simple hydraulic circuit

The basic operation of a Hydraulic valve involves a movable element (spool, poppet, or gate) that interacts with a stationary port configuration. By positioning this element, the valve changes which ports are connected, altering the flow path through the system.

Actuation methods for moving this element vary, including manual operation, hydraulic pilot signals, solenoids, or even computer-controlled servos in advanced systems. Regardless of the actuation method, the core function remains consistent: precise control of hydraulic fluid to achieve desired system performance.

Classification of Hydraulic Valves

Hydraulic valves are categorized based on their primary function within a hydraulic system. While there are many specialized designs, most Hydraulic valve types fall into three main categories, each serving distinct purposes in controlling hydraulic fluid.

Directional Control Valves

Directional control valves are the most commonly recognized type of Hydraulic valve. Their primary function is to control the path of hydraulic fluid through a system, determining which components receive fluid and in which direction it flows.

The simplest directional Hydraulic valve is a check valve, which allows flow in one direction only. More complex designs include spool valves with multiple positions and ports that can direct flow between various components.

Common Configurations:

- 2-way valves: Control flow between two ports

- 3-way valves: Direct flow between a supply port and one of two outlet ports

- 4-way valves: The workhorse of many systems, directing flow to and from actuators

Directional control Hydraulic valve specifications include the number of ports (ways) and the number of positions the valve can assume. For example, a 4/3 valve has 4 ports and 3 positions.

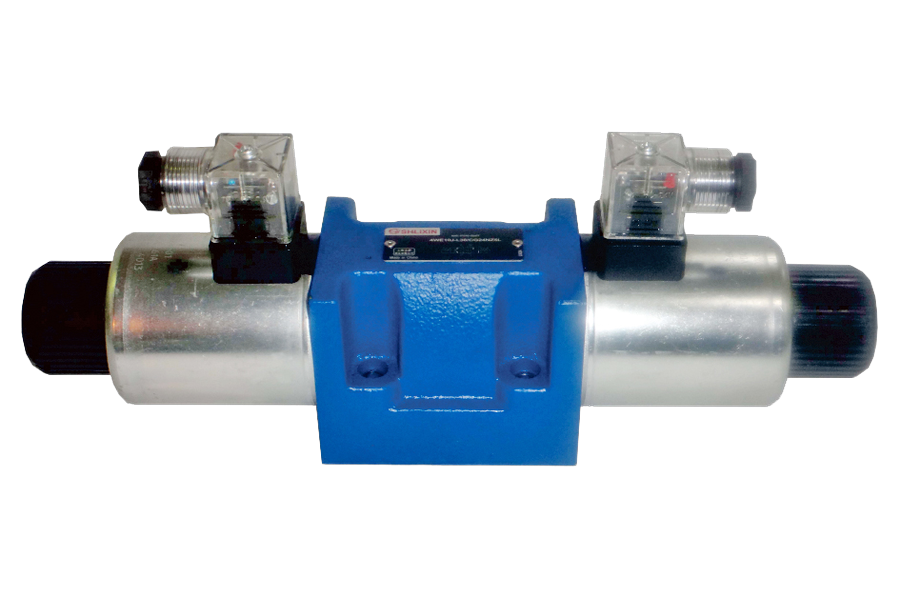

4-Way Directional Hydraulic Valve

Spool design allows precise control of fluid direction

Pressure Control Valves

Pressure Relief Hydraulic Valve

Protects system components from overpressure conditions

Pressure control valves regulate the pressure within hydraulic systems, ensuring it stays within safe and effective operating ranges. This type of Hydraulic valve is critical for preventing system damage and ensuring consistent performance.

A pressure relief Hydraulic valve is perhaps the most important safety component in any hydraulic system, opening to relieve excess pressure when it exceeds a preset limit. Other pressure control designs manage pressure in specific parts of the system.

Types of Pressure Control Valves:

- Relief valves: Protect systems from overpressure

- Reducing valves: Maintain lower, constant pressure in secondary circuits

- Sequence valves: Enable one operation to complete before another starts

- Unloading valves: Direct fluid back to tank at low pressure when not needed

Pressure settings on these valves are typically adjustable, allowing system designers to tailor performance to specific application requirements.

Flow Control Valves

Flow control valves regulate the rate at which hydraulic fluid moves through a circuit. Since the speed of hydraulic actuators is directly proportional to flow rate, this type of Hydraulic valve effectively controls the speed of machine movements.

A basic flow control Hydraulic valve uses an adjustable orifice to restrict flow. More sophisticated designs incorporate pressure compensation to maintain consistent flow rates regardless of pressure fluctuations in the system.

Key Designs:

- Needle valves: Provide fine flow control through a tapered needle and seat

- Gate valves: Use a sliding gate to control flow volume

- Pressure-compensated flow control valves: Maintain consistent flow despite pressure changes

- Proportional flow control valves: Allow remote adjustment of flow rates

Precision flow control is essential for operations requiring accurate speed regulation, such as in manufacturing processes where timing is critical.

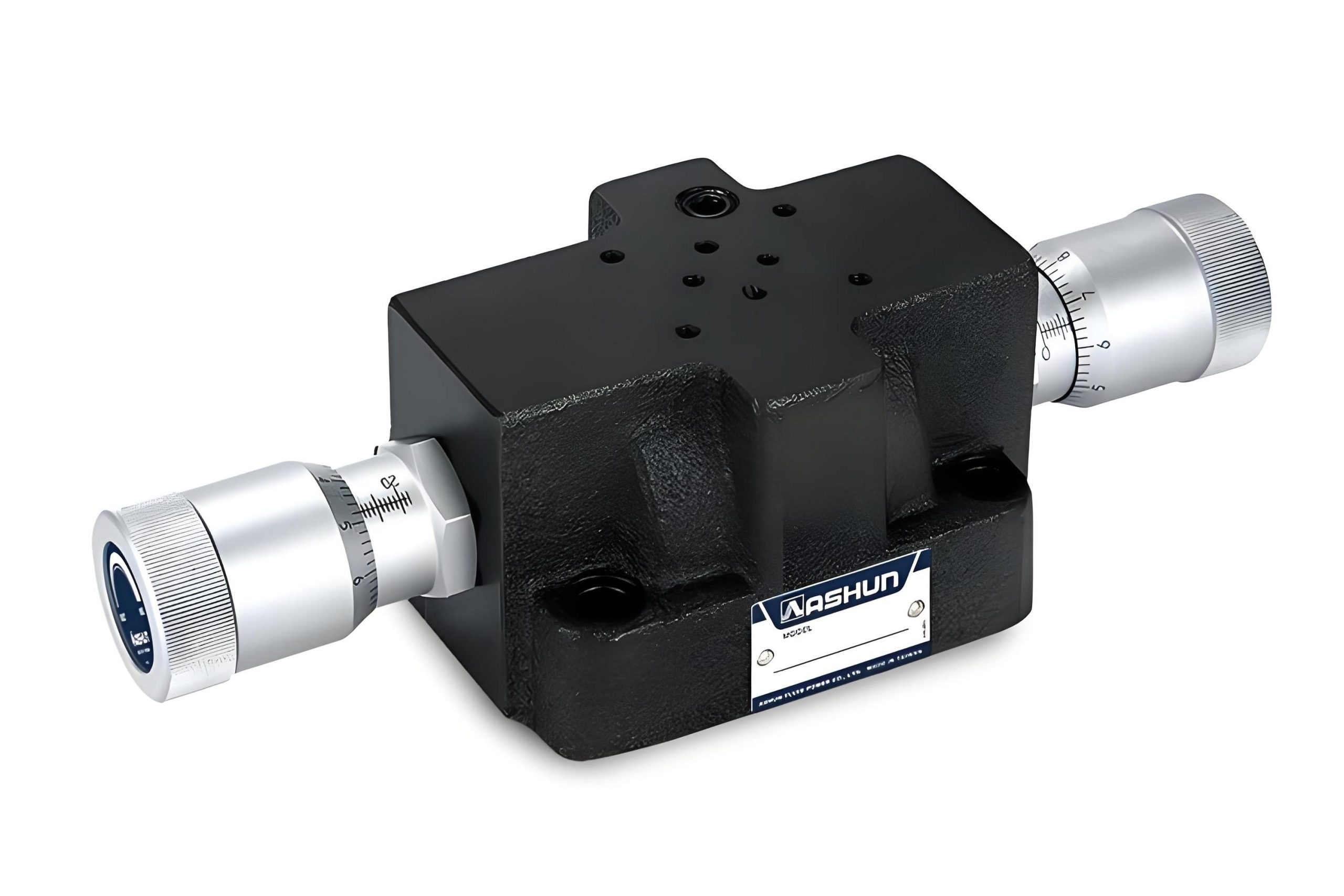

Precision Flow Control Hydraulic Valve

Enables accurate speed control of hydraulic actuators

Specialized Hydraulic Valve Designs

Beyond the three primary categories, numerous specialized Hydraulic valve designs exist for specific applications:

- Servo valves: Offer extremely precise control for applications like flight simulators

- Proportional valves: Provide variable control proportional to an electrical input signal

- Cartridge valves: Compact design allows modular system construction

- Counterbalance valves: Prevent loads from falling due to gravity

- Shuttle valves: Allow flow from two sources to a single destination

- Manifold valves: Combine multiple Hydraulic valve functions in a single block

Hydraulic Valve Manufacturing Processes

The production of a high-quality Hydraulic valve demands precision engineering and advanced manufacturing techniques. Even minor imperfections can compromise performance, making manufacturing processes critical to the functionality and reliability of every Hydraulic valve.

Material Selection

The manufacturing process begins with careful material selection based on the Hydraulic valve's intended application. Common materials include:

- Carbon steel for general applications

- Stainless steel for corrosion resistance

- Brass for low-pressure applications

- Special alloys for high-temperature or extreme environments

Material selection impacts not only the Hydraulic valve's performance but also its manufacturing processes and final cost.

Heat Treatment

Many Hydraulic valve components undergo heat treatment to optimize their mechanical properties:

Key machining processes include:

- Hardening and tempering for wear resistance

- Annealing to reduce internal stresses

- Case hardening for components needing hard surfaces and tough cores

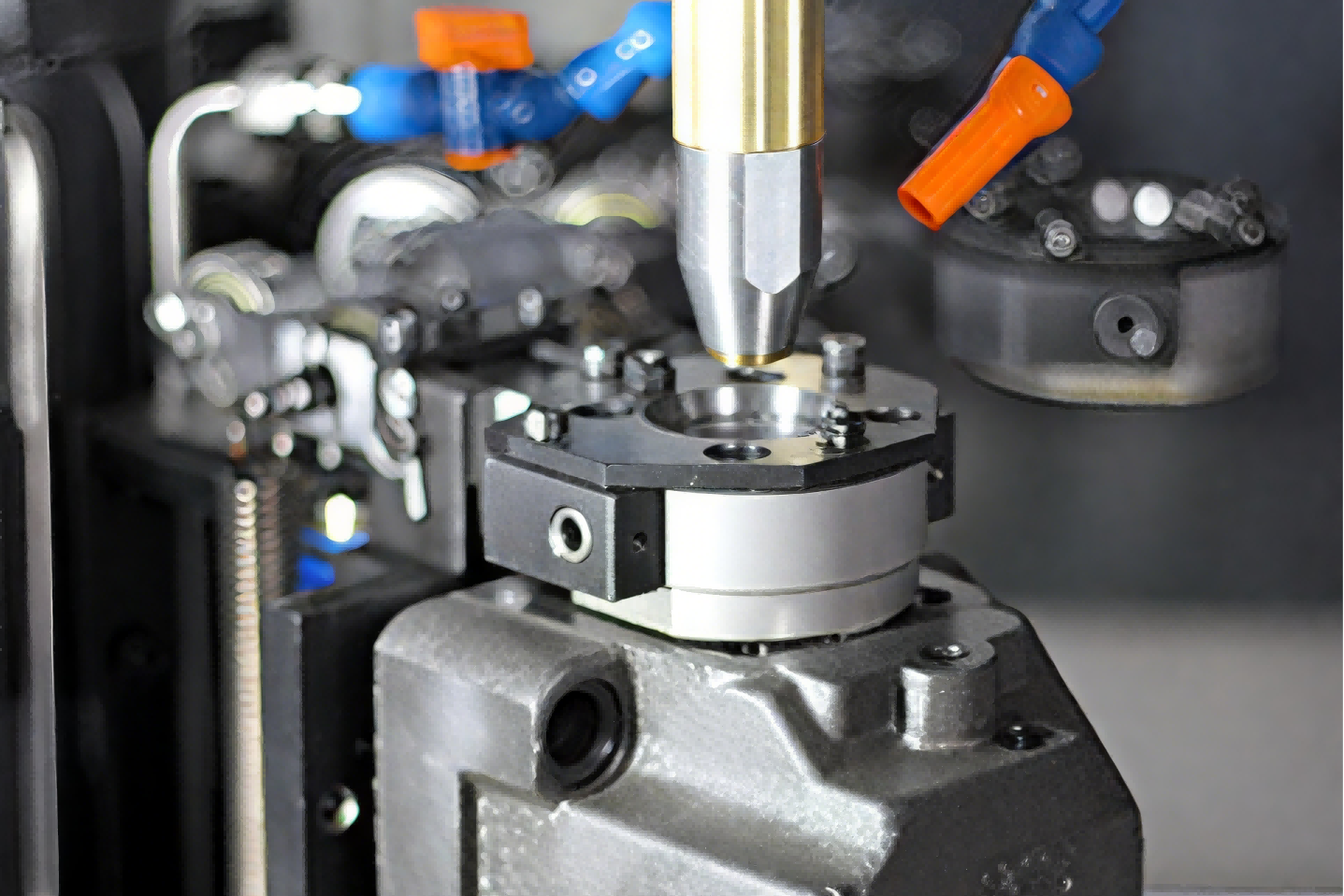

Precision Machining

The critical components of a Hydraulic valve require extremely precise machining to ensure proper operation. Tolerances as tight as 0.001mm may be required for valve spools and bodies.

- CNC turning for cylindrical components

- CNC milling for complex shapes and ports

- Grinding for final surface finish and dimensional accuracy

- EDM (Electrical Discharge Machining) for intricate features

Material selection impacts not only the Hydraulic valve's performance but also its manufacturing processes and final cost.

Surface Finishing

Surface treatments enhance the performance and longevity of a Hydraulic valve:

- Plating (chrome, nickel) for wear resistance and corrosion protection

- Anodizing for aluminum components

- Polishing to reduce friction and improve fluid flow

- Special coatings for extreme environments

Surface finish is particularly important for sealing surfaces and moving parts within the Hydraulic valve.

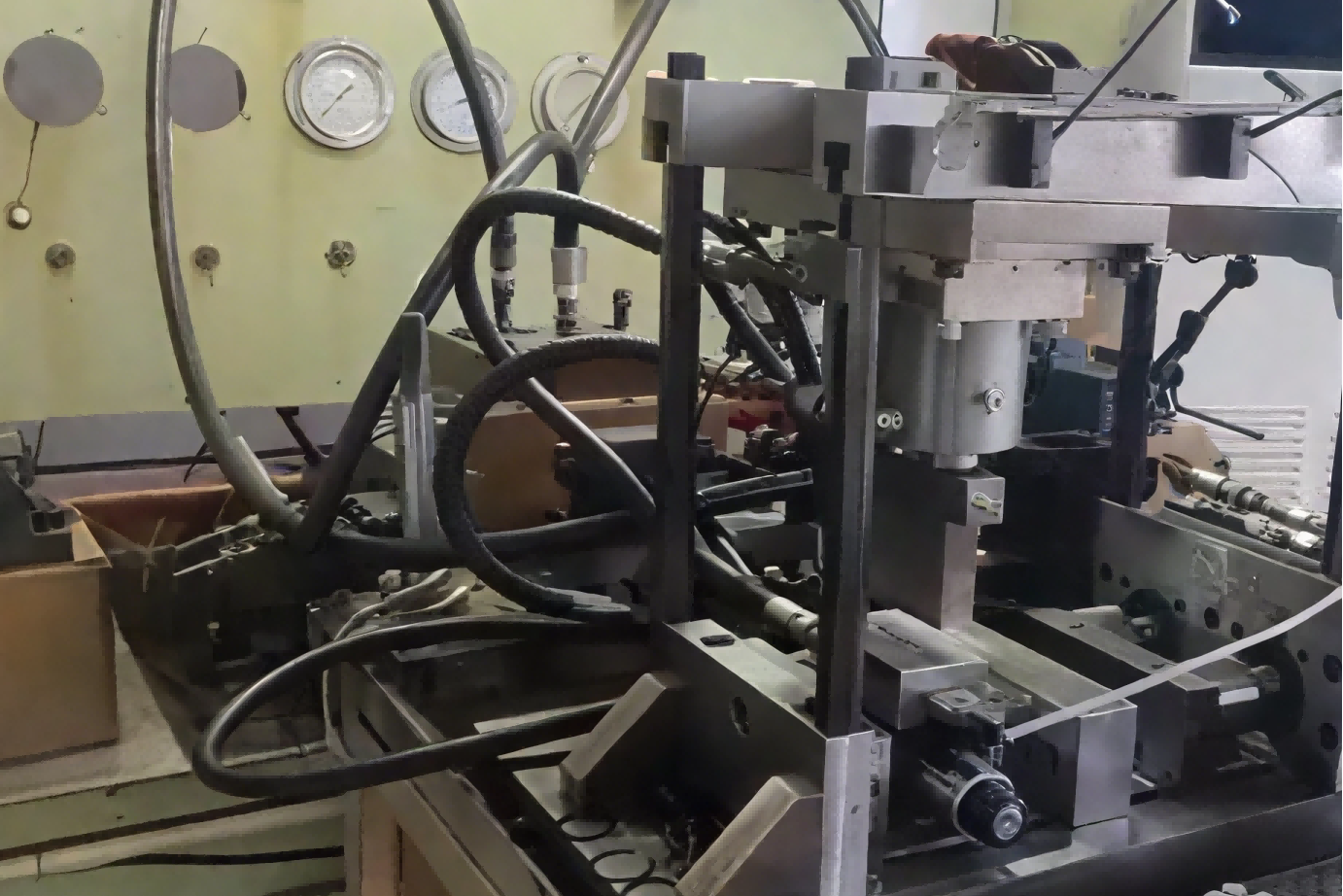

Assembly and Testing

The final stages of Hydraulic valve production involve careful assembly and rigorous testing:

- Cleanroom assembly to prevent contamination

- Torque-controlled fastening of components

- Pressure testing to verify integrity

- Performance testing across operating range

- Leak testing using precision instruments

Statistical process control ensures consistent quality across production runs of identical Hydraulic valve models.

Quality Control in Hydraulic Valve Production

Quality control is paramount in Hydraulic valve manufacturing, with multiple inspection points throughout the production process:

Dimensional Inspection

Coordinate Measuring Machines (CMMs) verify critical dimensions to ensure each Hydraulic valve meets design specifications.

Material Testing

Samples from each material batch undergo testing to confirm mechanical properties before being used in Hydraulic valve production.

Performance Validation

Each Hydraulic valve undergoes functional testing to ensure it operates correctly across its specified pressure and flow ranges.

Modern manufacturing facilities employ statistical process control and automated inspection systems to maintain consistent quality in Hydraulic valve production.

Hydraulic Valve Applications

The versatility of hydraulic systems makes the Hydraulic valve a critical component in countless industrial, mobile, and aerospace applications. Anywhere precise control of force, speed, and movement is required, a Hydraulic valve plays an essential role in regulating system performance.

Industrial Machinery

In factory settings, the Hydraulic valve controls presses, injection molding machines, material handling equipment, and robotic systems:

- Hydraulic presses use pressure control valves to regulate force

- Robotic arms rely on proportional valves for precise movement

- Conveyor systems use directional valves to control actuators

In these applications, a Hydraulic valve must provide consistent performance over millions of cycles with minimal maintenance.

Construction and Mining

Heavy machinery depends on rugged Hydraulic valve designs to withstand harsh environments:

- Excavators use multiple directional valves for arm movements

- Mining equipment employs specialized valves for high-pressure applications

- Bulldozers utilize flow control valves for precise blade positioning

Construction-grade Hydraulic valve components must resist contamination and operate reliably in extreme temperatures.

Marine Applications

Ships and offshore platforms utilize specialized Hydraulic valve designs resistant to corrosion:

- Steering systems use precise control valves

- Cargo handling equipment relies on heavy-duty valves

- Offshore drilling rigs employ explosion-proof valve designs

Marine Hydraulic valve components often feature stainless steel construction and special seals to resist saltwater corrosion.

Aerospace and Defense

The aerospace industry demands the highest performance from every Hydraulic valve:

- Aircraft landing gear uses lightweight, high-strength valves

- Flight control systems employ servo valves for precise movement

- Military vehicles require ruggedized valve designs

Aerospace Hydraulic valve components must meet stringent safety standards and weight requirements while operating flawlessly in extreme conditions.

Agricultural Equipment

Modern farming relies on hydraulic systems with durable valves:

- Tractors use valves for implement control

- Harvesters employ flow control for various functions

- Irrigation systems use specialized valves for water control

Agricultural Hydraulic valve designs must handle dust, debris, and varying weather conditions while maintaining reliability.

Mobile Hydraulics

Numerous mobile applications depend on compact, efficient Hydraulic valve designs:

- Fire trucks use valves for ladder and pump control

- Waste collection vehicles employ specialized valves

- Material handling equipment uses proportional controls

Mobile applications require Hydraulic valve components that balance performance with size, weight, and energy efficiency.

Hydraulic Valve Selection Criteria

Choosing the right Hydraulic valve for an application requires considering several factors:

Performance Requirements

- Operating pressure range

- Flow rate capacity

- Response time

- Leakage characteristics

Environmental Factors

- Temperature range

- Contamination risks

- Corrosion potential

- Vibration and shock levels

System Integration

- Mounting configuration

- Port sizes and types

- Actuation method

- Compatibility with fluids

Hydraulic Valve Maintenance and Troubleshooting

Proper maintenance is essential to ensure the longevity and reliable performance of any Hydraulic valve. A well-maintained Hydraulic valve can operate efficiently for thousands of hours, while neglect can lead to premature failure and costly downtime.

Preventive Maintenance Practices

Preventive maintenance helps avoid unexpected Hydraulic valve failures. Key practices include:

Fluid Analysis and Maintenance

Regular oil sampling and analysis detects contamination that can damage a Hydraulic valve. Maintaining proper fluid levels and changing filters according to schedule prevents many common valve issues.

Temperature Monitoring

Excessive temperature can degrade hydraulic fluid and damage a Hydraulic valve. Monitoring system temperatures identifies potential issues before they cause valve failure.

Regular Inspection

Visual inspections of Hydraulic valve components for leaks, corrosion, or damage can identify problems early. Checking mounting bolts for proper torque prevents vibration-related issues.

Scheduled Overhauls

Following manufacturer recommendations for Hydraulic valve overhauls ensures worn components are replaced before they cause system failures. This includes replacing seals, springs, and other wear items.

Hydraulic Valve Troubleshooting Guide

When a Hydraulic valve malfunctions, systematic troubleshooting can identify the root cause:

| Symptom | Possible Causes | Solutions |

|---|---|---|

| Valve fails to actuate |

|

Check electrical connections, clean valve, replace spring if necessary |

| Excessive leakage |

|

Replace seals, repair or replace damaged components, ensure proper assembly |

| Erratic operation |

|

Flush system, check pressure control valves, inspect and replace worn parts |

| Pressure control issues |

|

Readjust valve, clean or replace orifice, replace sensing element |

Hydraulic Valve Repair Best Practices

When repairing a Hydraulic valve, following proper procedures ensures reliable performance:

- Use clean workspaces to prevent contamination during repair

- Follow manufacturer guidelines for disassembly and reassembly

- Replace all wear components, not just those obviously damaged

- Use only recommended replacement parts for the specific Hydraulic valve model

- Calibrate the valve according to specifications after repair

- Test repaired valves before reinstallation in the system

Proper documentation of repairs helps track Hydraulic valve performance over time and identifies patterns in failure modes.

Contamination Control

Contamination is the leading cause of Hydraulic valve failure. Effective contamination control includes:

Sources of Contamination

- Particulate matter from manufacturing or wear

- Water ingress from condensation or leaks

- Air bubbles from improper filling or leaks

- Chemical contamination from incompatible fluids

Prevention Methods

- Use proper filtration with appropriate micron ratings

- Ensure clean fluid handling during maintenance

- Seal systems properly to prevent ingress

- Follow proper fluid storage and handling procedures

- Implement regular fluid testing protocols

Developments in Hydraulic Valve Technology

The Hydraulic valve continues to evolve as material science, manufacturing techniques, and control systems advance. These innovations are driving improvements in efficiency, precision, and sustainability across all applications of hydraulic technology.

Smart Hydraulic Valves

The integration of sensors and microprocessors into Hydraulic valve designs enables real-time monitoring of performance parameters. These smart valves can self-diagnose issues, communicate with system controllers, and even adjust their operation for optimal efficiency.

Additive Manufacturing

3D printing technology is revolutionizing Hydraulic valve production, allowing complex internal geometries that optimize flow characteristics. Additive manufacturing reduces waste, enables rapid prototyping, and creates opportunities for performance improvements not possible with traditional machining.

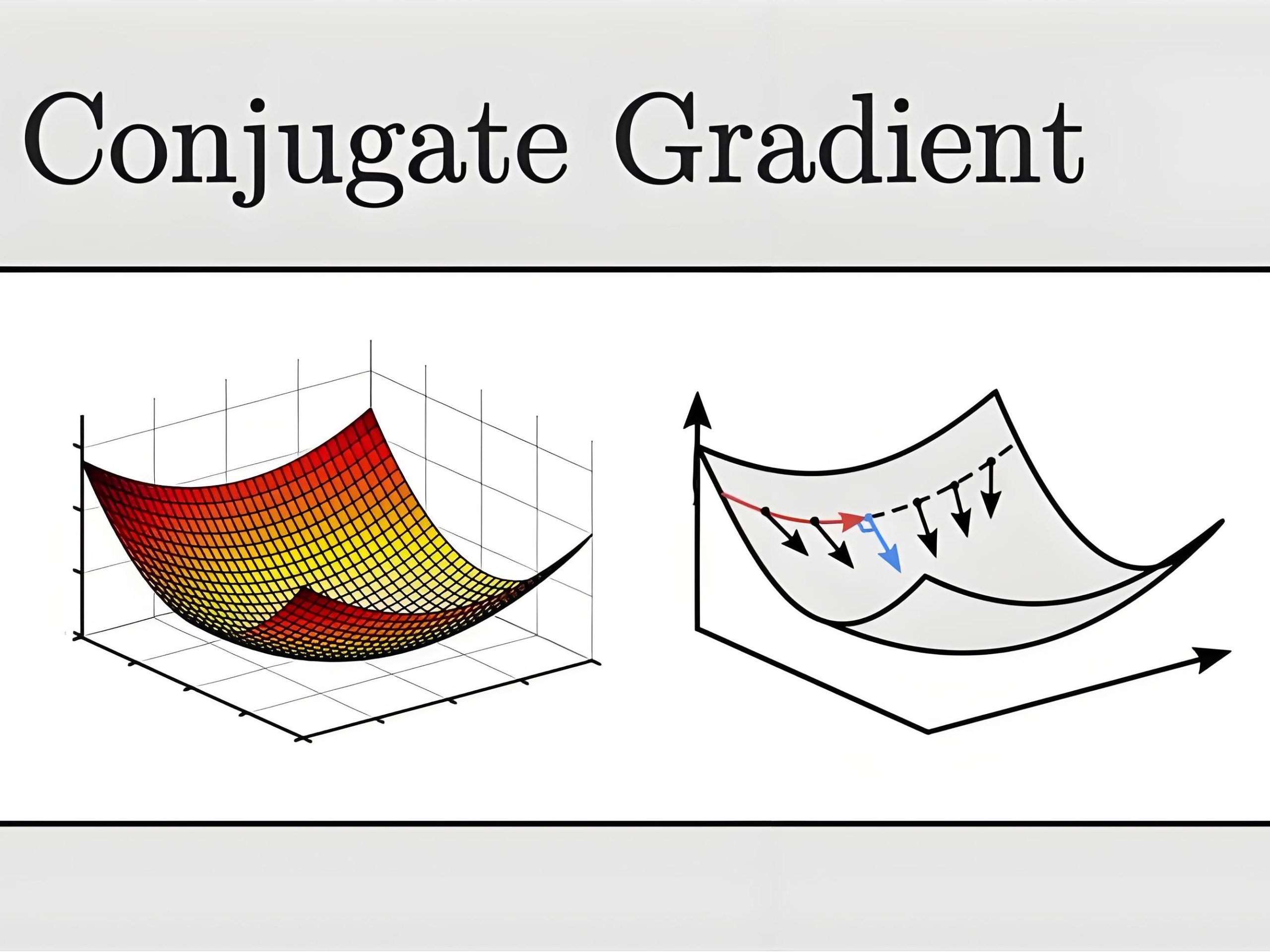

Computational Design

Advanced computational fluid dynamics (CFD) allows engineers to optimize Hydraulic valve designs for maximum efficiency. These simulations predict flow patterns, pressure drops, and potential cavitation issues before physical prototypes are built, accelerating development cycles.

Sustainability Trends in Hydraulic Valve Design

Environmental concerns are driving significant innovations in Hydraulic valve technology, focusing on energy efficiency and reduced environmental impact:

Energy Efficiency Improvements

Next-generation Hydraulic valve designs minimize pressure drops and energy losses while maintaining performance. This includes:

- Optimized flow paths to reduce turbulence

- Proportional control for precise energy use

- Regenerative circuits that capture and reuse energy

- Low-power actuation systems for valve controls

Eco-Friendly Materials and Fluids

The Hydraulic valve of the future will work with new environmentally friendly fluids and materials:

- Biodegradable hydraulic fluids

- Recyclable materials in valve construction

- Reduced use of rare earth elements in actuators

- Longer-lasting components to reduce waste

Integration with Industry 4.0

The industrial internet of things (IIoT) is transforming how hydraulic systems, including Hydraulic valve components, are monitored and controlled:

- Networked Hydraulic valve systems that communicate with central controllers

- Predictive maintenance based on real-time performance data

- Adaptive control systems that optimize valve performance based on operating conditions

- Digital twins that simulate Hydraulic valve behavior for virtual testing

- Remote monitoring and adjustment capabilities

This connectivity enables unprecedented levels of system optimization and efficiency, with the Hydraulic valve serving as a critical data node in intelligent hydraulic systems.

Emerging Applications and Technologies

New frontiers in Hydraulic valve technology are expanding the capabilities of hydraulic systems:

Miniaturized Hydraulic Valves

Micro-hydraulic systems for medical devices and small-scale automation require tiny, precise valves that maintain performance at reduced scales.

High-Pressure Systems

Advancements in materials science are enabling Hydraulic valve designs that operate at extremely high pressures, reducing system size while maintaining power output.

Self-Healing Technologies

Research into self-healing seals and adaptive components could lead to Hydraulic valve designs that automatically compensate for wear and minor damage.

Multi-Functional Valves

Integrating multiple functions into a single Hydraulic valve reduces system complexity, improves efficiency, and lowers costs.

The Hydraulic valve stands as a cornerstone of modern fluid power systems, enabling the precise control that makes hydraulic technology indispensable in countless applications. From the simplest check valve to sophisticated proportional control systems, the Hydraulic valve has evolved into a highly engineered component that balances performance, durability, and efficiency.

As we've explored, understanding the principles, types, manufacturing processes, and maintenance requirements of these valves is essential for anyone working with hydraulic systems. The ongoing development of smarter, more efficient Hydraulic valve designs promises to further expand the capabilities and applications of hydraulic technology in the future.

Whether in industrial machinery, construction equipment, aerospace systems, or emerging technologies, the Hydraulic valve will continue to play a vital role in powering and controlling the mechanical systems that shape our modern world.