Menu

Let us first understand the history of hydraulic technology. As we can see, hydraulic technology has continuously evolved in the course of industrial development to adapt to industrial needs and improve performance:

1795

British inventor Bramah invented the first hydraulic press, opening hydraulic engineering applications.

1905

Working medium changed from water to oil, achieving a qualitative breakthrough.

1940s

Electrohydraulic servo control technology emerged.

1960s

Electrohydraulic proportional control technology was born.

1970s – Present

Continuous development toward high pressure, large flow, and integration.

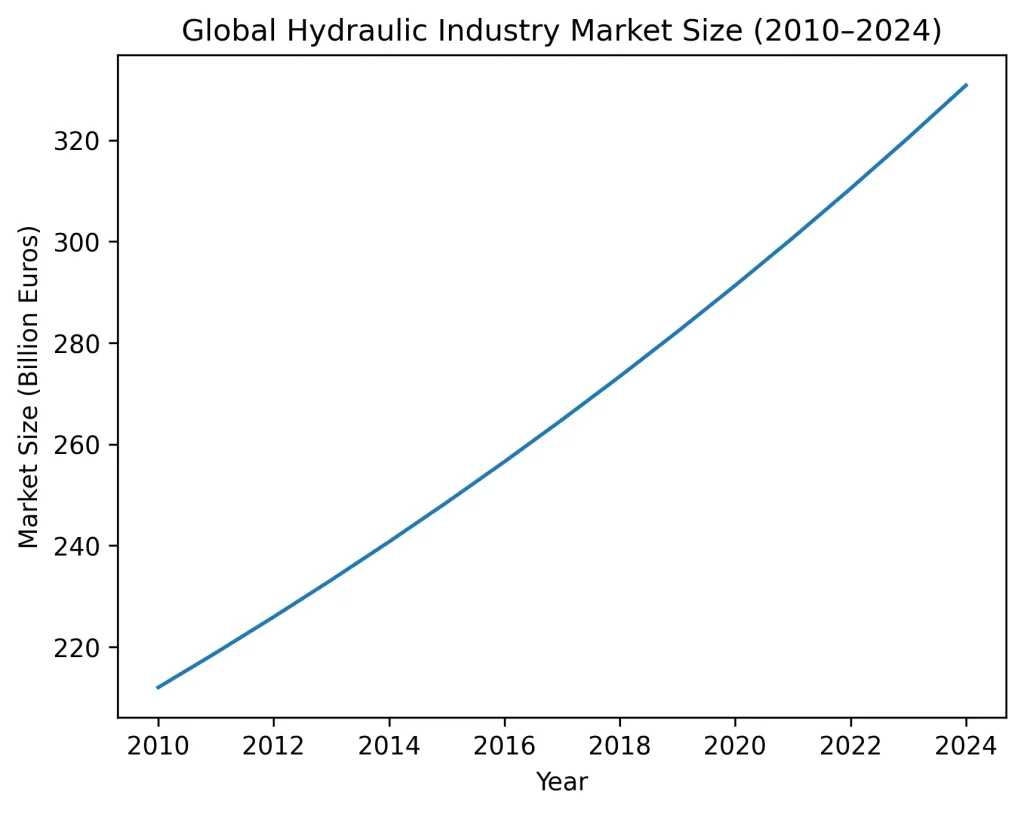

As hydraulic technology continues to advance, we can expect the global market size to grow as well. Indeed, this is the case. Let’s examine the market growth:

As shown in this market size chart, the global hydraulic market size has been consistently growing, increasing from US$21.2 billion in 2010 to US$38.9 billion in 2024, with a CAGR of 3.23%.

The subsequent market report forecasts that it will grow to US$44.26 billion by 2030, with a CAGR of 2.4% (data source: Marketsandmarkets).

Key factors driving market growth include:

Looking at the data alone, hydraulic technology performs well in the market in terms of high efficiency and power saving, but we still need to analyze the actual situation.

Hydraulic technology is widely used today in various industries, including CNC machine tools, construction machinery, and passenger/freight elevators. It improves production efficiency and safety while simultaneously reducing costs. In the field of machinery, hydraulic technology, thanks to its high performance and resilience, enables powerful operation with relatively small volume, thus meeting the requirements of demanding industrial applications. When compared with other power technologies, its advantages are readily apparent:

| Comparison Dimension | Hydraulic Transmission | Electric Transmission | Mechanical Transmission |

| Power Density | Extremely High | Moderate | Low |

| Load Capacity | Powerful | Moderate | Limited |

| Response Speed | Fast | Extremely Fast | Slow |

| Volume and Weight | Compact | Moderate | Bulky |

| Position Accuracy | High | Extremely High | Moderate |

| Overload Protection | Excellent | Requires Additional Protection | Easily Damaged |

| Energy Recovery | Highly Efficient (up to 75%) | Moderate (~25%) | Difficult |

The advantages of hydraulic technology are particularly evident in demanding applications and high power output, making it indispensable in fields such as construction machinery and metallurgical plants.

A large market size also means increased engineering requirements. Hydraulic systems are not without their flaws, and they also present some difficult challenges to overcome during operation, The following are some common problems encountered when using conventional hydraulic systems:

In order to flexibly adapt to various industrial needs and solve the various problems of traditional hydraulic systems, a large number of “digital hydraulic” technologies have emerged in the hydraulic industry, which is undoubtedly a breakthrough.

Digital hydraulics technology actually has many forms; we’ll briefly discuss these three main ones:

These digital hydraulic technologies have led to the development of digital hydraulic products, laying the foundation for overall digital hydraulic systems and providing new ideas for hydraulic system design that better meet industrial needs.

Digital Hydraulic Cylinder

A digital hydraulic cylinder (also known as a digital oil cylinder or electro-hydraulic stepping cylinder) is a high-tech hydraulic transmission and control product that organically combines a cylinder, digital servo valve, sensor, and digital servo control structure into a single integrated device. It achieves the digitalization of the motion characteristics of the hydraulic actuator: the frequency of electrical pulses corresponds to the speed of the hydraulic actuator, and the number of electrical pulses corresponds to the displacement of the actuator. Changes in load, system pressure, fluid characteristics, and even leakage do not affect the required characteristics of the hydraulic actuator.

Digital hydraulic cylinders are particularly suitable for transmission systems requiring high-precision speed and position control, and coordinated motion control, especially in high-flow or ultra-high-flow (kiloliters/minute), high-frequency or ultra-high-frequency servo control applications, where they offer unparalleled competitive advantages and high cost-effectiveness.

Digital Hydraulic Motor

The digital hydraulic motor (also known as a digital oil motor or electro-hydraulic stepping motor) also adopts a digital characteristic design and is particularly suitable for transmission systems requiring high-precision speed and torque control, and coordinated motion control. It performs exceptionally well in low-speed, high-torque, high-precision angular control, and high-frequency or ultra-high-frequency servo control applications.

Digital Hydraulic Pump

The digital hydraulic pump (digital programmable power-sensitive pump) can be directly connected to a computer or network bus, precisely controlling its hydraulic displacement output and the work it performs. It can achieve programmable power output and adapt to load-sensitive, constant-power, and other operating conditions, making it one of the excellent devices for achieving efficient and energy-saving hydraulic operation.

The energy-efficient servo-hydraulic system achieves real-time precise matching of flow rate, pressure, and power through the integration of simulation and optimization algorithms. The system employs an intelligent optimization algorithm-driven adaptive PID control strategy that utilizes feedforward control technology to make adjustments before flow rate changes occur, enabling smooth transitions to target states and converting abrupt step changes into gradual ramp changes.

The ingenious aspect of this design lies in reducing the difficulty of oil film formation in the hydraulic pump’s sliding pairs, which effectively increases service life and minimizes the inertia of the accelerating fluid, pump, and motor, thus reducing unit losses. Depending on operating conditions and load rates, energy savings can reach 20% to 60%. In terms of pressure response performance, the response time of the intelligent pump station is reduced from 100-120 milliseconds of traditional pump stations to less than 100 milliseconds, the average noise level is reduced from 85 decibels to 70 decibels, and fluid consumption is reduced to an average of 60% of the original.

The gravity potential energy recovery hydraulic system achieves perfect dynamic matching between the energy storage device (hydraulic accumulator group + power grid) and sudden, variable loads. It creatively utilizes the pressurized hydraulic fluid from a closed system in an open circuit, transforming the volumetric closed circuit into a semi-closed circuit, allowing for periodic fluid replacement based on operating conditions This solves common problems in closed loops, such as cleanliness and heat dissipation, leakage, and lock-up, without affecting energy efficiency.

The system’s energy-saving effect is between 60% and 75%, which is 50% higher than the best energy-saving accumulator high-low pressure technology currently available on the market.

This system, composed of a hydraulic power system, pressure sensors, and a data acquisition and processing unit, can collect real-time flow rate, volume, and pressure parameters of the hydraulic system. After establishing a mathematical model of the hydraulic cylinder’s flow rate and volume requirements, the system compares theoretical flow rates with actual measured data to detect leaks, pressure anomalies, and accumulator status in the hydraulic system, thereby achieving intelligent diagnosis.

The system combines pressure sensors and a mathematical model of accumulator pressure changes to achieve real-time monitoring of the main pump’s volumetric efficiency, providing timely warnings when deviations exceed the set range. Simultaneously, the system establishes a hydraulic system health assessment method and standards based on node importance, facilitating efficient maintenance, optimized management, and fault prediction of the hydraulic system.

Hydraulic hybrid technology combines hydraulic and electric drive systems, enabling efficient recovery and reuse of vehicle braking energy. When the vehicle brakes, the hydraulic system stores energy and releases it when needed. This technology boasts an energy recovery rate of up to 75%, significantly improving fuel efficiency.

Artificial intelligence technology is deeply penetrating all aspects of hydraulic systems. Through machine learning algorithms, the system can automatically optimize control parameters based on historical operating data, achieving adaptive adjustment. In terms of fault diagnosis, the constructed hydraulic fault knowledge base covers 3800 failure modes, and the AI diagnosis accuracy is 41% higher than traditional empirical judgment.

AI reinforcement learning technology has begun to be applied to the control optimization of complex hydraulic systems. For example, the COMAC C929 aircraft wing hydraulic actuation system uses AI reinforcement learning technology, significantly improving the system’s response accuracy and reliability.

Electro-hydraulic integration represents an important development direction for hydraulic technology. By integrating pressure sensors, temperature sensors, and displacement sensors into the hydraulic system, these “sensory organs” can monitor oil pressure, oil temperature, flow rate, and the position of the actuators in real time. After the data is transmitted to the electronic controller, it is quickly analyzed and processed through built-in algorithms to precisely adjust the opening of the electro-hydraulic proportional valve or servo valve, achieving precise control of the speed, force, and position of the hydraulic actuators.

Electro-hydraulic actuators integrate multiple components, reducing piping and connections and thus lowering the risk of leaks. They also support distributed hydraulic systems, making the system more reliable and easier to maintain. Through IoT technology, the hydraulic system can also achieve remote monitoring and data sharing, facilitating predictive maintenance.

Sunward Intelligent’s 5G remote-controlled excavator uses digital hydraulic technology to achieve precise remote control. Operators can remotely control the excavator’s operation through the 5G network, with system latency controlled at the millisecond level, and the operating accuracy is the same as on-site operation. This technology not only improves operational safety but also provides a new solution for engineering operations in hazardous environments.

The COMAC C929 aircraft’s wing hydraulic actuation system utilizes AI reinforcement learning technology. Through training with extensive flight data, the system can automatically optimize control strategies under complex flight conditions, controlling the precise movements of critical components. This application signifies a new advancement in hydraulic technology within the aerospace sector.

The digital hydraulic system of the “Fendouzhe” manned submersible maintains precise and reliable operation even in the extreme high-pressure environment of the ten-thousand-meter-deep sea. The system utilizes advanced pressure compensation technology and sealing design, ensuring the safety and reliability of deep-sea operations.

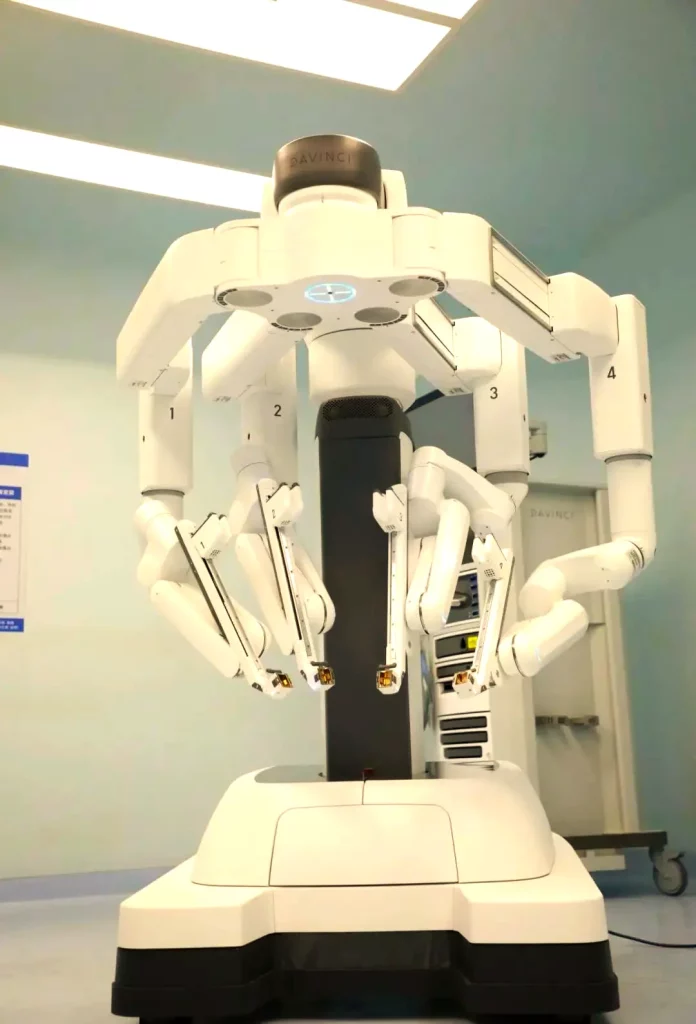

The upgraded Da Vinci surgical robot uses magnetorheological digital hydraulic technology to achieve ultra-precise control of surgical instruments. Magnetorheological fluid can instantly change its viscosity under the action of a magnetic field, allowing the system to provide force feedback ranging from extremely soft to quite rigid, helping doctors gain better tactile perception during minimally invasive surgery.

Heterogeneous Computing Technology: The digital hydraulic controller integrates FPGA+NPU dual chips, capable of completing 4096 pressure-flow coupling calculations within 1 millisecond, with power consumption controlled within 15 watts. This technological breakthrough gives the hydraulic system real-time ultra-high-speed computing capabilities, providing computational power assurance for precise control under complex working conditions.

Multi-Physics Field Modeling: The hydraulic-mechanical-thermal coupling simulation platform developed by Tsinghua University can accurately predict the aging state of seals after 20,000 hours, with an accuracy of 92%. This technology provides a scientific basis for the life prediction and preventive maintenance of hydraulic systems.

Knowledge Graph Technology: The constructed hydraulic fault knowledge base covers 3800 failure modes, structuring and storing a large amount of expert experience and historical fault data. This makes AI diagnosis 41% more accurate than traditional experience-based judgment, significantly improving the efficiency and accuracy of fault diagnosis.

Through in-depth exploration of digital hydraulic technology and intelligent systems, and understanding the applications of innovative technologies such as digital hydraulics, servo energy saving, and intelligent diagnostics, one cannot help but marvel at the rapid pace of technological development. Hydraulic technology has been around for over 200 years, and its future potential is immeasurable. The application of innovative technologies has not only solved the problems of high energy consumption, difficult monitoring, and slow fault response in traditional hydraulic systems, but has also opened up broad development prospects for hydraulic technology.

Pozoom Hydraulic is a leading supplier of hydraulic equipment. We utilize advanced hydraulic technology to design and customize high-efficiency hydraulic systems for construction machinery, and are committed to providing our customers with efficient and reliable hydraulic solutions.