Menu

Threaded cartridge hydraulic valves first appeared in the United States in the early 1950s, used as relief valves mounted on aircraft fuel pump bodies (two-port). Due to their light weight and compact structure, they were gradually adopted by industries such as agriculture and mining. However, in the 1960s, they were still limited to simple two-port functions (such as check valves, relief valves, and 2/2 solenoid valves), used in medium-low pressure and small flow applications. The main manufacturer was Fluid Control Company in the United States.

Around 1970, Fluid Control’s distributors in Europe and America became independent one after another (such as Modular Controls in the US, Sun Hydraulics, Sterling Hydraulics in the UK, Wandfluh in Switzerland, Comatrol in Italy, etc.), and threaded cartridge valves developed into multi-port, multi-function designs.

In the 1980s, full-range suppliers emerged, and threaded cartridge valves became generally accepted by the market. In the 1990s, breakthroughs came with the application of 3D design software and CNC machining centers for manifolds.

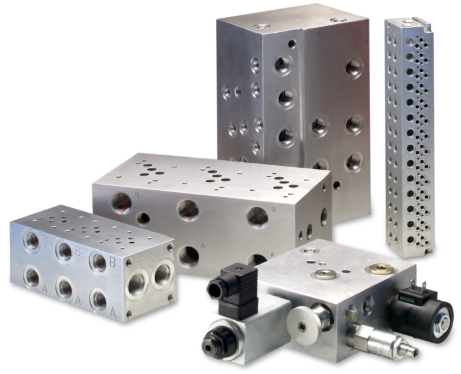

Threaded cartridge valves have no castings; components are suitable for high-volume automated machining, have many common parts, and can easily combine different functions. Production costs are lower than equivalent subplate/line-mounted valves. After decades of R&D, the product range is extremely broad (except for servo valves, they can achieve all other hydraulic valve functions), becoming the mainstream form of hydraulic valves, with varieties exceeding ten thousand:

Special design varieties are several times the basic types. Manufacturers continuously improve and introduce new products to meet users’ special requirements. Control performance and reliability have improved, with widespread applications squeezing the market share of subplate valves, line-mounted valves, and modular valves, becoming essential for modern hydraulics (especially mobile equipment hydraulics). Their manifold form (compact hydraulics) is the preferred choice for hydraulic systems, with growth rates 2-3 times that of other hydraulic components (Eaton 2003 report).

Since the 21st century, hydraulic giants have successively acquired threaded cartridge valve manufacturers:

HydraForce sales: $100 million in 2003 → $330 million in 2015 → $470 million in 2018; slogan: “Uncompromisingly compact, endlessly customizable.”

Threaded cartridge valve and manifold sales: approximately $750 million in 2006 → $1.5 billion in 2012 → $2 billion in 2016; 2018 sales volume: HydraForce 13 million units, HYDAC 6.6 million units, Sun Hydraulics 6.1 million units, Bosch Rexroth 5 million units; on July 15, 2022, Bosch Rexroth acquired HydraForce.

Currently, over 100 companies worldwide can supply threaded cartridge valves and manifolds, but very few can supply a complete product range. Suppliers each have their own characteristics and compete with each other; no single company can currently provide all types.

The core characteristic of threaded cartridge valves is flexible application. Main methods include:

At inception, there was only 3/4″-16 thread, two-port. Later, 3-6 port designs developed. In the 1970s, each company developed their own cavities, resulting in non-unified cavities that were not interchangeable (manufacturers welcomed this situation to lock in customers).

In 1982, major users like Ford and Caterpillar pushed for international standards. In 1998, ISO 7789 (metric thread) was barely passed (advocates: Bosch, Rexroth, etc.; contributors: Bucher, Tries of Germany, etc.).

Two years later, 12 US manufacturers proposed standard draft CAD 17209 for UN/UNF threads. European manufacturers opposed it on grounds of “insufficient safety and opposition to dual standards.” The draft did not become an international standard but instead became US national standard NFPA. Since 2008, the “TR17209” working group has been drafting UNF thread cavity international standards, which still exist today.

Market adoption of ISO 7789 has progressed slowly; no company has yet launched a complete ISO series valve. The October 2007 revision only refined dimensional definitions without changing the number of cavities; the situation has not fundamentally improved (user pressure would be needed to change this).

Cavities using UNF threads are known as ICC (Industry Common Cavity) (supported by HydraForce, etc.). ICC-08/10/16/20 cavities are basically similar but have local differences (interchanging may cause oil leakage); ICC-12 cavities are completely different.

Sun Hydraulics insists on its own cavity design (believing it has obvious advantages) and once occupied important international markets (Rexroth once distributed their products, and other companies also copied their cavities). After acquisitions by multinational corporations (Parker, Eaton, etc.), the acquired companies’ cavities were retained to satisfy existing customers, with no unified cavity series (e.g., Parker’s 2009 catalog listed 53 valve cavities).

Currently, the market has at least 3 well-known cavity series: ISO 7789, Sun, and ICC, plus numerous proprietary series from various manufacturers. “The trains have scattered in all directions, difficult to return to the same track.”

Countermeasures:

Limited by thread strength and tightening torque (maximum 500 N·m), ISO 7789:2007 only goes up to M42×2mm, resulting in:

Countermeasures: Mix different types in manifolds as needed: use subplate valves where necessary (e.g., NG6 subplate solenoid directional valve flow can reach 90 L/min); use cover-plate cartridge valves for high-flow sections.

Threaded cartridge valves started later than traditional line-mounted/subplate valves and are constrained by size and layout limitations. Early performance (flow/pressure drop, relief valve hysteresis, flow divider accuracy, dynamic response, durability, etc.) was inferior to traditional forms. Because mobile machinery is limited by space/weight, threaded cartridge valves were preferred despite lower performance requirements.

With technological development, some threaded cartridge valve performance has now approached or equaled traditional valves and is also used in stationary equipment hydraulics.

Countermeasures:

Building systems with threaded cartridge valves requires designing manifolds. Once manufactured, manifolds are difficult to modify (circuit changes require redesign), making development cycles longer than line-mounted/modular components.

Countermeasures:

Threaded cartridge valve manufacturing is technology-, capital-, labor-, and management-intensive:

8 types of pilot valves + 6 types of springs + 18 types of pilot valve seats + 16 types of valve bodies can combine into 13,824 solenoid directional valves with different performance characteristics. Computer management of drawings, process cards, parts, etc. is required, with significant difficulty.