Menu

When your production line stops, money walks out the door. That's what a mid-sized manufacturing plant in Ohio learned after experiencing five major hydraulic failures in eight months.

Their story shows you what happens when you ignore your hydraulic tank. More importantly, it reveals the exact steps they took to fix the problem.

Inspection Results

What The Inspection Revealed

The specialist spent two days analyzing their systems. His findings painted a troubling picture of long-neglected design issues.

Contamination Levels Were Alarmingly High

Fluid samples showed ISO 4406 cleanliness codes of 22/20/17. Industry standards recommend 16/14/11 for their type of equipment.

They were operating at contamination levels five times higher than recommended, dramatically increasing wear and failure rates of critical components.

Excessive contamination leads to premature failure of pumps, valves, and seals, increasing maintenance costs and unplanned downtime.

Financial Impact

The Cost They Didn't See

Before they fixed anything, the operations manager calculated the real cost of their hydraulic tank problems, revealing a much larger financial impact than initially thought.

Unplanned Downtime Cost Comparison

The Fix

The Solution They Implemented

The plant decided to redesign their hydraulic tanks rather than replace the entire system. The specialist recommended a five-phase approach that addressed all root causes.

1

2

3

4

5

Implementation Timeline

The entire modification took six weeks. Three weeks for parts procurement and three weeks for installation, done during scheduled maintenance windows to minimize production impact.

Outcomes

The Results Nobody Expected

The changes delivered impressive results within the first month, with continued improvements over time.

Impressive Return on Investment

The payback period was just 11 months. After that, every dollar saved went straight to their bottom line.

A $15,000 investment in tank modifications saved them $287,000 in the first year alone. That's an impressive 19:1 return on investment.

But the real value wasn't just money saved. It was production reliability restored, maintenance staff spending time on improvements instead of emergency repairs, and operators confident their equipment would run when needed.

Key Insights

What Made This Work

Three critical factors drove their remarkable success and can be applied to any hydraulic system improvement project.

"The hydraulic tank market is projected to grow from $19.04 billion in 2023 to $30.7 billion by 2030, which signals increasing recognition of proper tank design. But growth doesn't help if you don't apply the fundamentals correctly."

— Plant Operations Manager

They also learned that tank size matters less than tank design. A well-designed smaller tank outperforms a poorly-designed larger tank every time.

The global industrial hydraulic equipment market was valued at $37.5 billion in 2024 and is expected to reach $52.6 billion by 2033. That's a lot of equipment relying on properly designed tanks.

Practical Advice

Five Things You Can Check Today

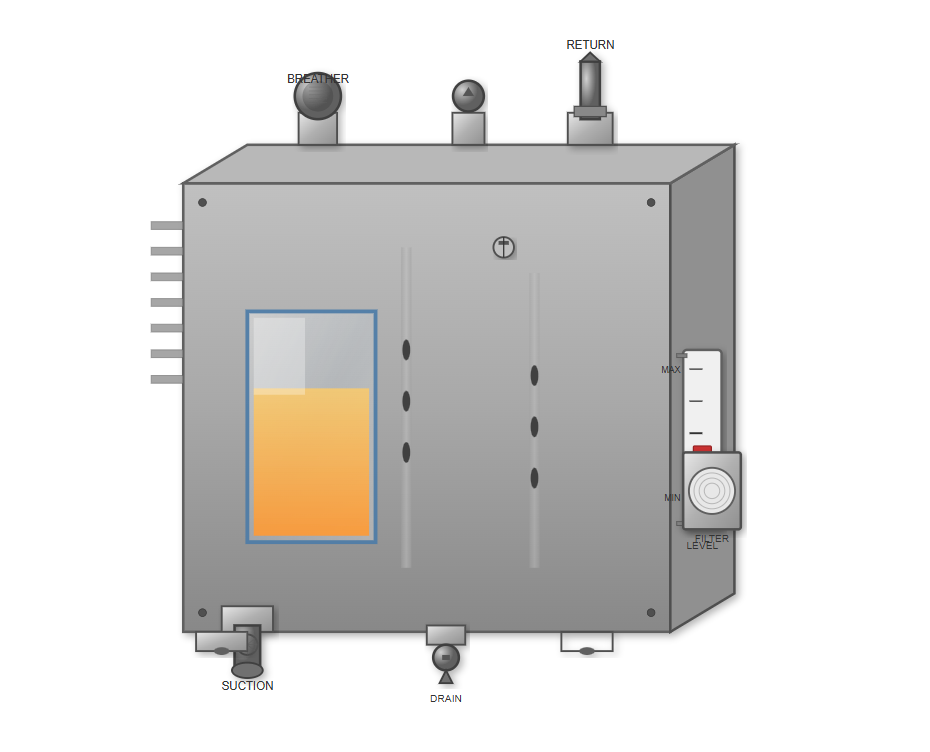

You don't need a consultant to spot basic hydraulic tank problems. Here's what to look for to identify potential issues in your own systems.

Key Takeaways

Lessons That Apply Everywhere

This manufacturing plant wasn't special. They faced problems that affect thousands of facilities running hydraulic equipment.

Next Steps For Your Operation

You don't need to redesign your entire hydraulic system to see improvements. Start small and build on your success.

-

Start with one system. Pick the one causing you the most problems. Apply the principles from this case study. Measure the results.

-

Get your fluid analyzed. This gives you baseline data to measure improvements against. Most industrial fluid suppliers offer this service.

-

Talk to your maintenance team. They know which systems fail most often. They see the patterns you might miss from reports alone.

-

Consider the total cost of your current approach. Add up downtime, replacement parts, fluid costs, and maintenance labor. Compare that to the cost of proper tank design.

The manufacturing plant in this case study isn't unique. They just decided to stop accepting failures as normal. You can make the same choice.

Common Questions

FAQ About Hydraulic Tank Problems

Answers to the most frequently asked questions about hydraulic tank design, maintenance, and performance.