Menu

Introduction

This comprehensive guide explores the principles, designs, and applications of hydraulic pumps and motors, essential components in modern fluid power systems that convert mechanical energy to hydraulic energy and back.

Pump Technologies

Detailed analysis of gear, vane, and piston pump designs

Motor Systems

Comprehensive overview of hydraulic motor technologies

Performance Data

Comparative analysis of efficiency and applications

Section 1: Overview

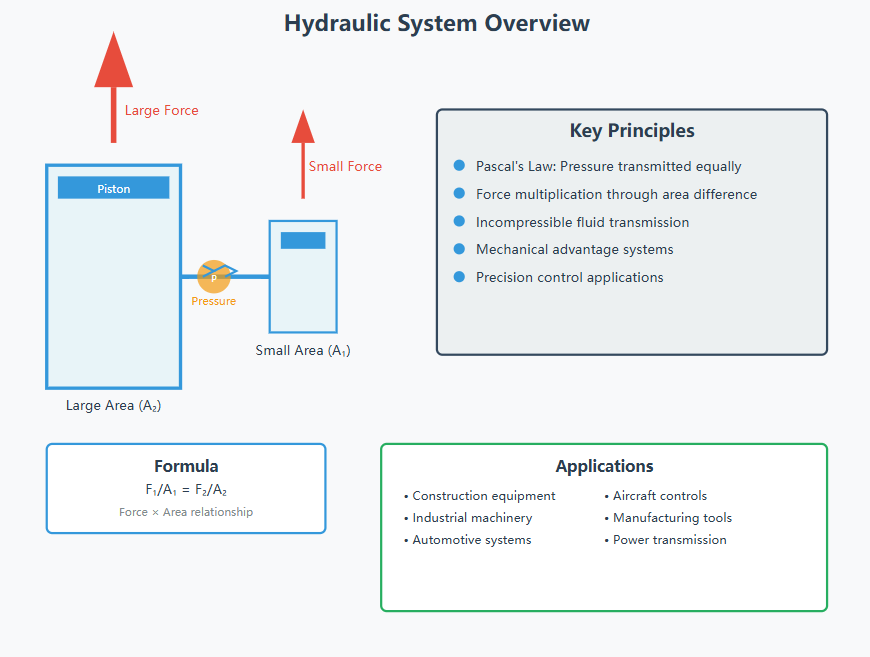

The hydraulic pump stands as one of the most fundamental components in modern fluid fluid power systems, converting mechanical energy into hydraulic energy through the pressurization of fluid. These remarkable devices have revolutionized industrial machinery, construction equipment, and countless other applications where substantial force transmission is required. Understanding the principles behind hydraulic pumps and motors is essential for anyone involved in mechanical engineering, industrial maintenance, or system design.

A hydraulic pump operates on the basic principle of creating flow by mechanically displacing fluid from an inlet to an outlet port. This displacement generates the pressure necessary to overcome system resistance and perform useful work. The relationship between flow rate, pressure, and power in a hydraulic pump follows fundamental fluid dynamics equations, making these devices predictable and reliable in their operation.

The evolution of hydraulic pump technology has been driven by the increasing demands of industry for higher pressures, improved efficiency, and greater reliability. From simple hand-operated pumps to sophisticated variable-displacement units controlled by electronic systems, the hydraulic pump has undergone continuous refinement.

When examining hydraulic pump selection criteria, engineers must consider multiple factors including required flow rate, operating pressure, fluid compatibility, environmental conditions, and noise levels. The choice of pump type significantly impacts system performance, maintenance requirements, and overall operating costs.

Key Principles of Hydraulic Pumps

- Convert mechanical energy to hydraulic energy through fluid pressurization

- Create flow by displacing fluid from inlet to outlet ports

- Generate pressure proportional to system resistance

- Operate on principles of fluid dynamics with predictable performance

- Available in various designs optimized for specific applications

Section 2: Gear Pumps

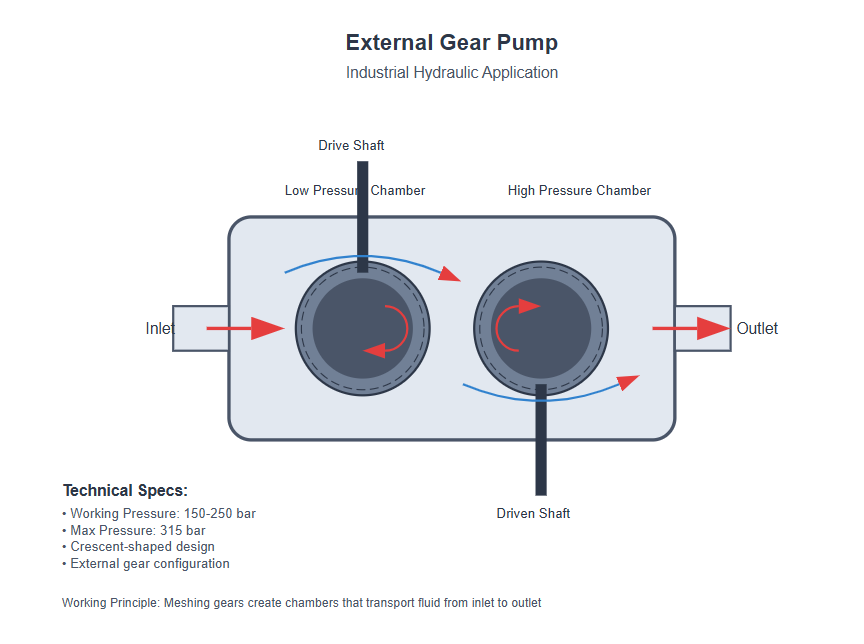

Gear pumps represent the most widely used type of hydraulic pump in industrial applications, primarily due to their simple construction, reliability, and cost-effectiveness. These positive displacement pumps utilize meshing gears to transfer fluid from the inlet to the outlet, creating a continuous flow that is proportional to the rotational speed of the gears.

The operational principle of a gear-type hydraulic pump involves the rotation of precisely machined gears that create expanding and contracting volumes within the pump housing. As the gears rotate and unmesh at the inlet side, they create a partial vacuum that draws fluid into the expanding tooth spaces.

Internal gear pumps offer an alternative configuration where a smaller external gear rotates within a larger internal gear, with a crescent-shaped partition separating the inlet and outlet ports. This design provides several advantages over external gear pumps, including lower noise levels, higher volumetric efficiency at low speeds, and the ability to handle fluids with varying viscosities.

The performance characteristics of gear pumps make them ideal for applications requiring moderate pressure and flow rates. Typical operating pressures range from 150 to 250 bar, with some specialized designs capable of reaching 315 bar.

Section 3: Vane Pumps

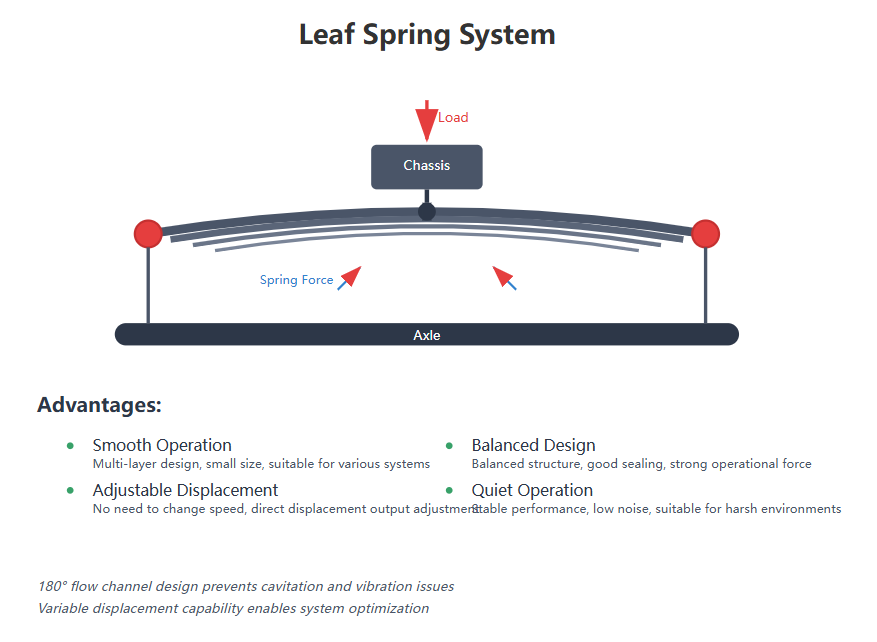

Vane pumps utilize sliding vanes mounted in a rotor to create the pumping action, offering smooth flow delivery and the capability for variable displacement in certain configurations. The basic design consists of a rotor eccentrically positioned within a cam ring, with rectangular vanes that slide in and out of slots in the rotor as it rotates.

The hydraulic pump mechanism in vane designs provides exceptionally smooth flow characteristics due to the multiple vanes continuously entering and leaving the pumping cycle. As the rotor turns, centrifugal force and hydraulic pressure push the vanes outward against the cam ring, maintaining a seal between adjacent pumping chambers.

Balanced vane pumps represent an evolution in design that addresses the radial loading issues inherent in unbalanced configurations. By incorporating two inlet and two outlet ports positioned 180 degrees apart, balanced vane pumps eliminate net radial forces on the rotor and bearings.

Variable displacement vane pumps offer sophisticated control capabilities that make them valuable in systems requiring varying flow rates. By adjusting the eccentricity of the cam ring relative to the rotor, these pumps can modify their displacement from maximum to zero flow while maintaining constant shaft speed.

Vane Pump Advantages

Smooth Flow Characteristics

Multiple vanes create consistent flow with minimal pulsation, ideal for sensitive systems

Variable Displacement Options

Ability to adjust flow output without changing rotational speed, improving energy efficiency

Balanced Designs Available

Eliminate radial loads on bearings, extending service life and enabling higher pressure operation

Quiet Operation

Smoother operation compared to gear pumps, making them suitable for noise-sensitive environments

Section 4: Piston Pumps

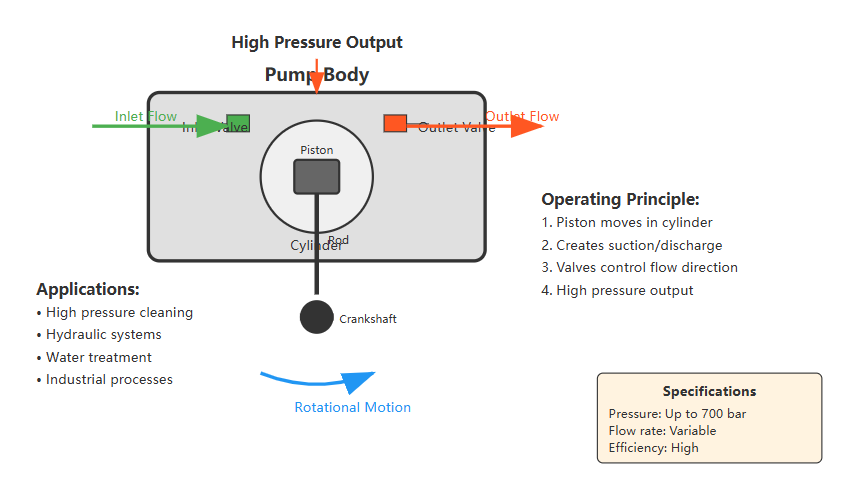

Piston pumps represent the pinnacle of hydraulic pump technology in terms of pressure capability and efficiency, utilizing reciprocating pistons to generate fluid flow. These sophisticated devices come in two primary configurations: axial piston and radial piston designs, each offering distinct advantages for specific applications.

Axial piston pumps arrange their pistons parallel to the drive shaft, with the pistons reciprocating within a cylinder block that rotates with the shaft. The hydraulic piston mechanism involves a swash plate or bent axis design that converts rotational motion into linear piston movement.

The bent axis configuration represents an alternative approach to axial piston pump design, where the cylinder block axis is positioned at an angle to the drive shaft axis. This arrangement eliminates the need for a swash plate, potentially reducing internal leakage and improving efficiency at high pressures.

Radial piston pumps position their pistons perpendicular to the drive shaft, typically utilizing an eccentric cam or crankshaft to create the reciprocating motion. These pumps excel in ultra-high pressure applications, with some designs capable of generating pressures exceeding 700 bar.

Piston Pump Configurations

| Pump Type | Pressure Range | Efficiency | Typical Applications |

|---|---|---|---|

| Axial Piston - Swash Plate | 210-350 bar | 90-95% | Industrial machinery, mobile equipment |

| Axial Piston - Bent Axis | 280-420 bar | 92-96% | Heavy machinery, marine applications |

| Radial Piston | 350-700+ bar | 88-94% | High-pressure industrial systems, test equipment |

Section 5: Performance Comparison and Applications

Understanding the comparative performance characteristics of different hydraulic pump types is crucial for selecting the optimal solution for specific applications. Each pump design offers unique advantages and limitations that must be carefully evaluated against system requirements, operating conditions, and economic considerations. The selection process involves analyzing factors such as pressure requirements, flow rate needs, efficiency expectations, noise constraints, and maintenance capabilities.

Gear Pumps

Excel in applications prioritizing simplicity, reliability, and cost-effectiveness over maximum efficiency or pressure capability.

Common Applications:

- • Lubrication systems

- • Machine tool hydraulic units

- • Agricultural tractors

- • Construction machinery

Pressure Range: 150-250 bar

Vane Pumps

Occupy a middle ground in the performance spectrum, offering better efficiency than gear pumps and smoother flow characteristics.

Common Applications:

- • Injection molding machines

- • Die-casting equipment

- • Machine tools

- • Automated production lines

Pressure Range: 140-175 bar

Piston Pumps

Dominate applications demanding maximum pressure capability, highest efficiency, and precise control in demanding environments.

Common Applications:

- • Hydraulic presses

- • Steel mill equipment

- • Aerospace systems

- • High-performance industrial systems

Pressure Range: 350+ bar

The integration of hydraulic pump motor combinations in modern systems requires careful consideration of compatibility and performance matching. The pump must provide adequate flow and pressure to meet the motor's requirements while operating within its optimal efficiency range. System designers must account for pressure losses, temperature effects, and dynamic loading conditions when selecting pump and motor combinations.

Section 6: Hydraulic Motors

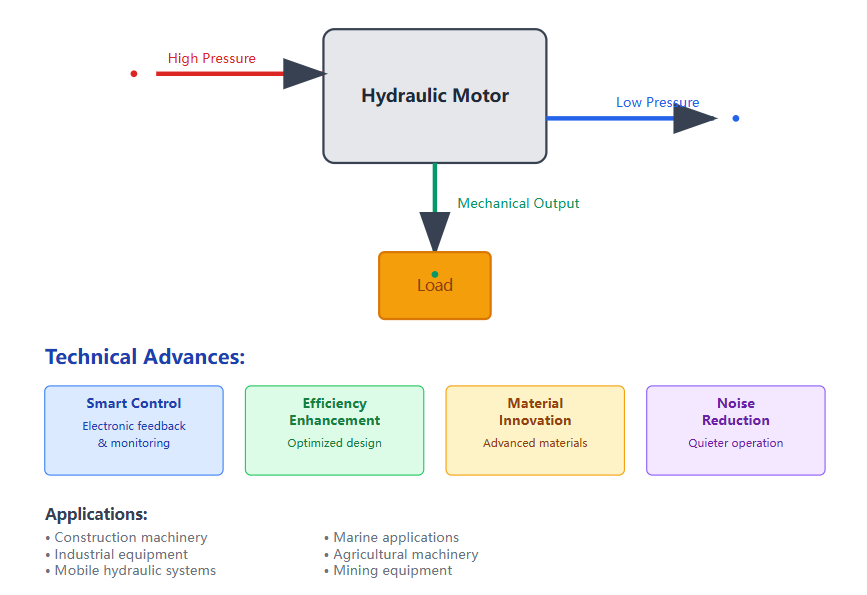

The hydraulic motor serves as the complementary component to the hydraulic pump, converting hydraulic energy back into mechanical energy to perform useful work. While hydraulic motors share many design similarities with pumps, their optimization for different operating conditions results in distinct performance characteristics.

Hydraulic motors operate on the reverse principle of pumps, using pressurized fluid to create mechanical rotation. The fundamental designs mirror those found in pumps: gear motors, vane motors, and piston motors, each offering specific advantages for different applications.

Gear motors provide economical solutions for applications requiring moderate torque and speed. Their simple construction and robust design make them suitable for conveyor drives, winch applications, and fan drives where precise speed control is not critical.

Vane motors offer smooth operation and good starting torque characteristics, making them suitable for applications requiring consistent low-speed performance. The balanced vane design provides uniform torque output with minimal pulsation.

Piston motors deliver the highest performance in terms of efficiency, pressure capability, and power density. Axial piston motors dominate high-speed applications, while radial piston motors excel in low-speed, high-torque applications.

Advancements in Hydraulic Motor Technology

The advancement of hydraulic motor technology continues to focus on improving efficiency, reducing noise, and extending service life:

Smart Controls Integration

Integration with sensors and electronic controls enables condition monitoring and predictive maintenance

Material Innovations

Advanced bearing designs and seal technologies enable operation at higher pressures and temperatures

Efficiency Improvements

Design optimizations have increased overall efficiency, reducing energy consumption and heat generation

Noise Reduction

Advanced designs and manufacturing techniques have significantly reduced operating noise levels

The comprehensive understanding of hydraulic pumps and motors forms the foundation for designing and maintaining efficient fluid power systems. From the simple reliability of gear pumps to the sophisticated performance of piston designs, each technology offers unique advantages that must be matched to application requirements. The continuous evolution of hydraulic pump and motor technology drives improvements in industrial productivity, energy efficiency, and operational reliability across diverse industries.

The future of hydraulic technology promises further advancements in efficiency, control precision, and integration with digital systems. Smart hydraulic components incorporating IoT connectivity and artificial intelligence will enable unprecedented levels of system optimization and predictive maintenance. As industries continue to demand higher performance and greater efficiency, the fundamental principles of hydraulic power transmission will remain relevant while the technology continues to evolve to meet these challenges.

The selection and application of hydraulic pumps and motors require careful consideration of numerous factors, from basic performance requirements to long-term maintenance implications. Engineers and technicians must stay informed about technological advances while maintaining a solid understanding of fundamental principles. This knowledge enables the design of hydraulic systems that deliver reliable, efficient performance while minimizing environmental impact and operating costs. The continued importance of hydraulic power transmission in industrial applications ensures that expertise in hydraulic pump and motor technology remains valuable for engineering professionals worldwide.